Steam cooking device and control method thereof

A cooking device and steam technology, which is applied to steam cooking utensils, timing control ignition mechanism, cooking utensils, etc., can solve the problems of users being scalded and unable to eliminate high-temperature steam in the oven cavity in time, and achieve the effect of avoiding food corruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

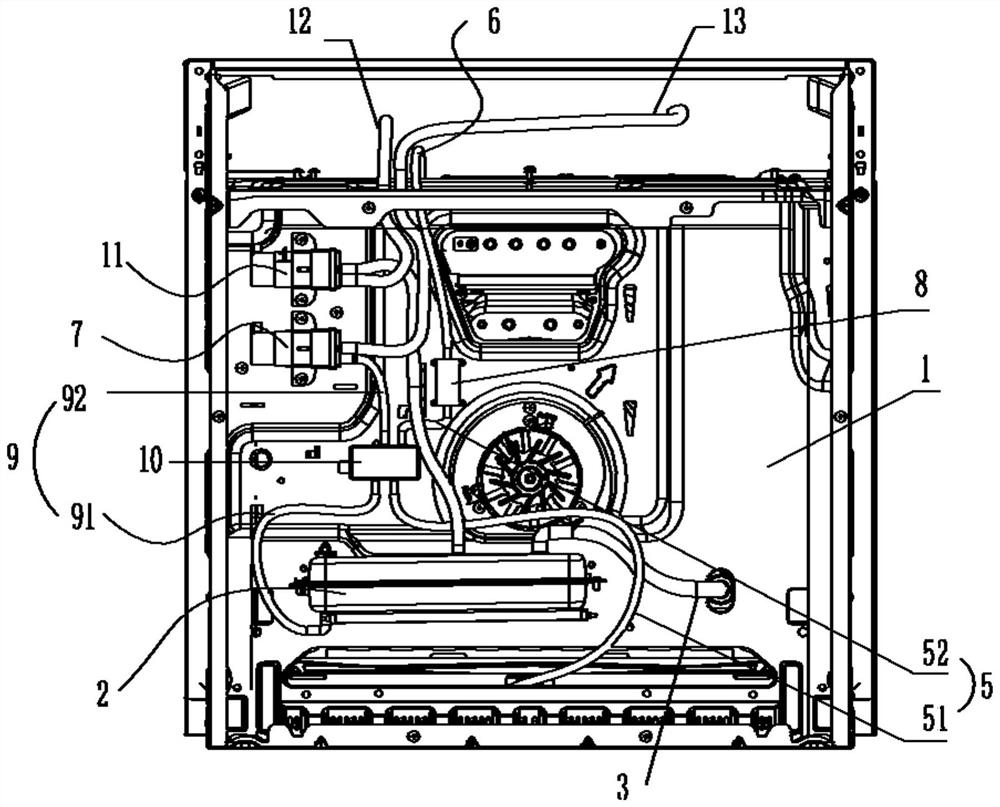

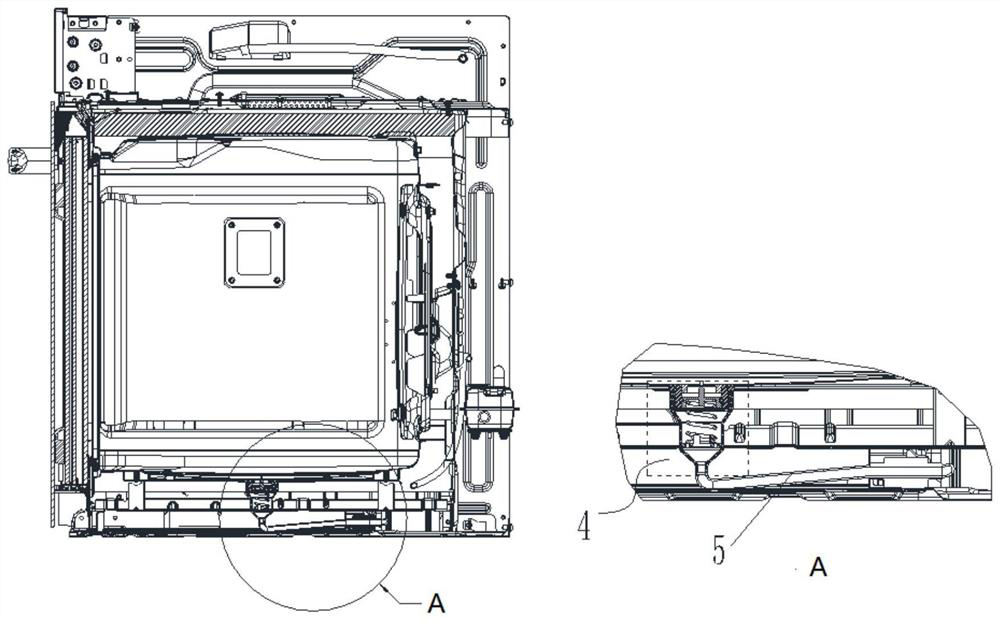

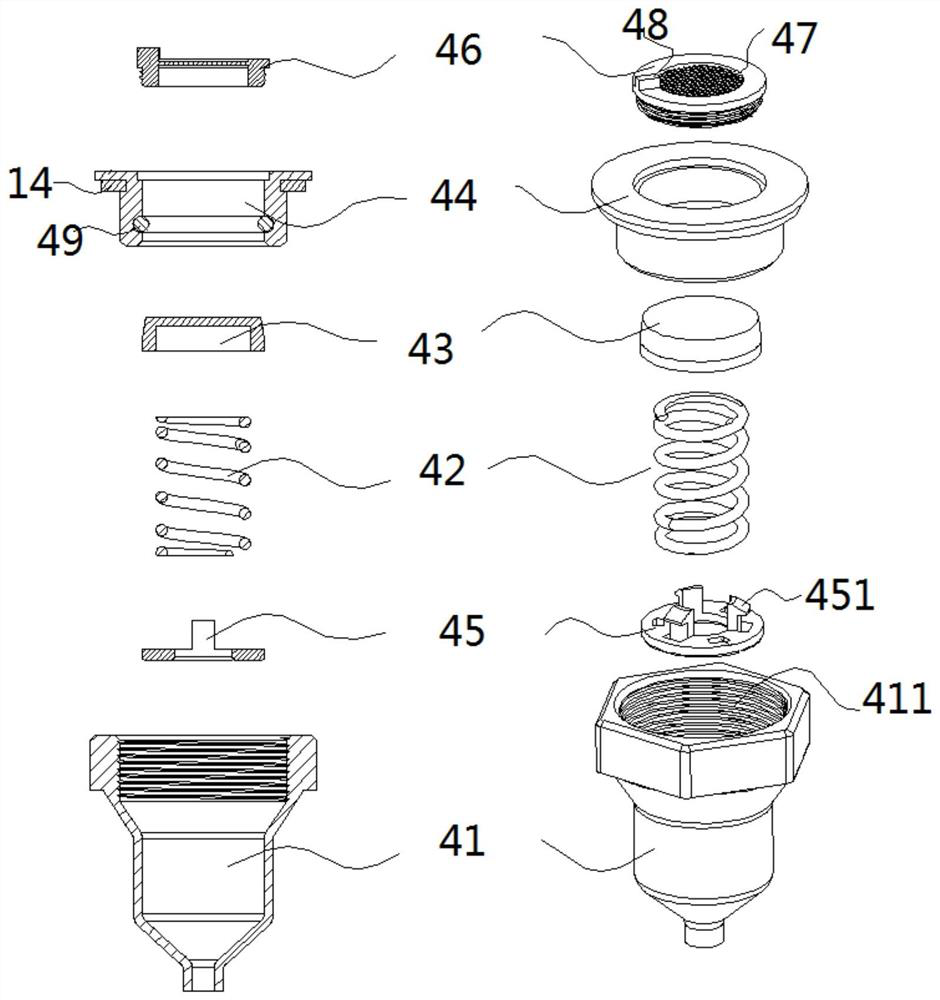

[0057] This embodiment provides a steam cooking device, such as Figure 1-Figure 5 As shown, in this embodiment, the steam cooking device can be a steamer, a steam oven, or a steamer, as long as the cooking device that can realize the cooking operation by steam is the steam cooking device in this embodiment.

[0058] The steam cooking device will generate high-temperature steam through the steam generator 2, and the high-temperature steam will exchange heat with the lower temperature inner cavity, food, cabinet door, etc.

[0059] In this embodiment, the steam cooking device includes:

[0060] The liner 1 is made of metal material, such as stainless steel. The ingredients to be cooked are placed in the inner pot 1, specifically, a steaming rack can also be set in the inner pot 1, and the inner pot 1 can be divided from the height direction by the steaming rack, so as to form different cooking spaces.

[0061] The inner tank 1 is provided with a door body, the door body is pr...

Embodiment 2

[0109] This embodiment provides a control method for a steam cooking device, which includes an inner tank connected with an exhaust pump, and a door lock is provided on the door of the inner tank, including the following steps:

[0110] S1. Obtain a cooking completion signal of the food to be cooked;

[0111] In this embodiment, the cooking completion signal can be determined by setting the cooking duration. For example, the timing starts after the steam cooking device is started. After 20 minutes, the food has been cooked by default, and the cooking completion signal is sent at this time.

[0112] S2. Obtain an opening signal of the door body;

[0113] There is no limitation on the manner of acquiring the opening signal of the door body. As an implementation manner, a pressure sensor may be provided on the door handle of the door body, and the user's door opening action may be judged by the pressure sensor. As another implementation manner, an infrared sensor may also be pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com