Full-automatic sand washer and sand washing process thereof

A sand washing machine, fully automatic technology, applied in the direction of mobile filter element filter, filter screen, grille, etc., can solve the problems of poor sand washing effect, sand washing can not be effectively dewatered, etc., to ensure the effect of sand washing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

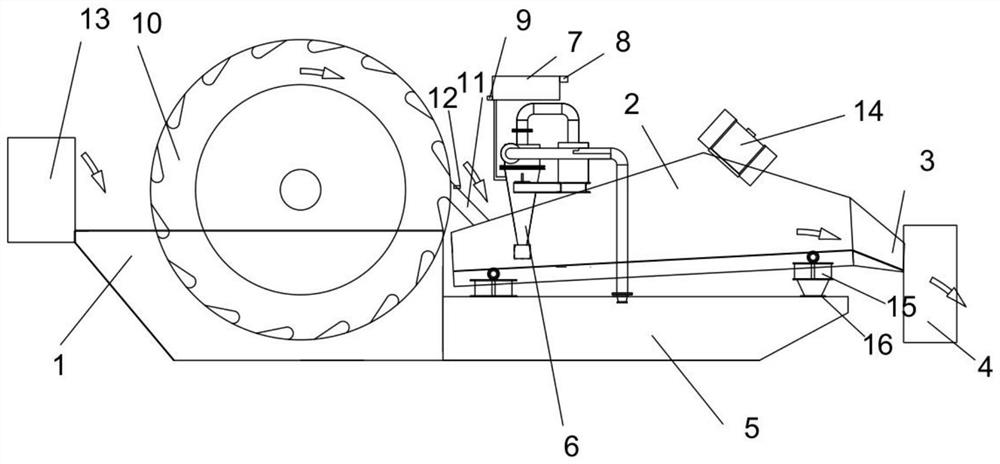

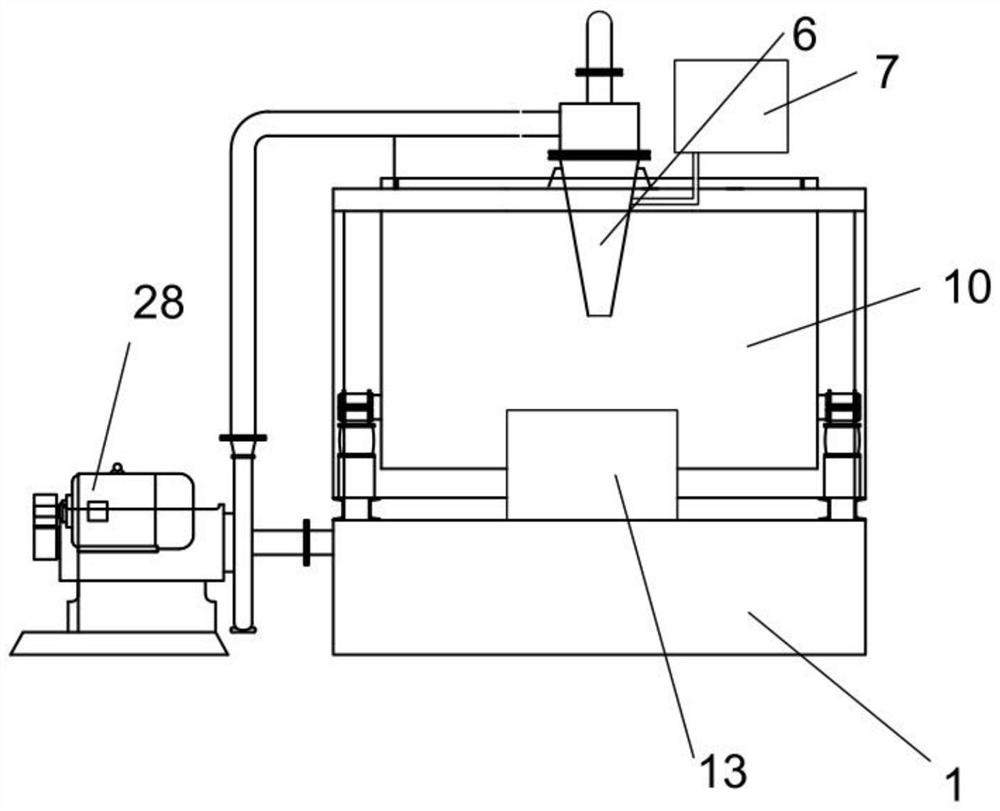

[0029] see Figure 1-Figure 2 , this embodiment provides a fully automatic sand washing machine, including a first water tank 1 for storing water and sand, the top of the first water tank 1 is an opening, and a high-frequency The dewatering screen 2 is connected with a finished product conveyor belt 3 at the large particle output end on the right side of the high frequency dewatering screen 2, and is connected with a finished product collection bin 4 at the other end of the finished product conveyor belt 3, and the bottom of the high frequency dewatering screen 2 is provided with The second water tank 5, the second water tank 5 is also connected with a cyclone 6 through the slurry pump 28, the sand outlet end on the cyclone 6 is connected to the high-frequency dewatering screen 2, and the cyclone 6 is The water outlet 8 is connected with a waste water sedimentation tank 7, the waste water sedimentation tank 7 is provided with a water outlet 8 and a mud outlet 9, the water outl...

Embodiment 2

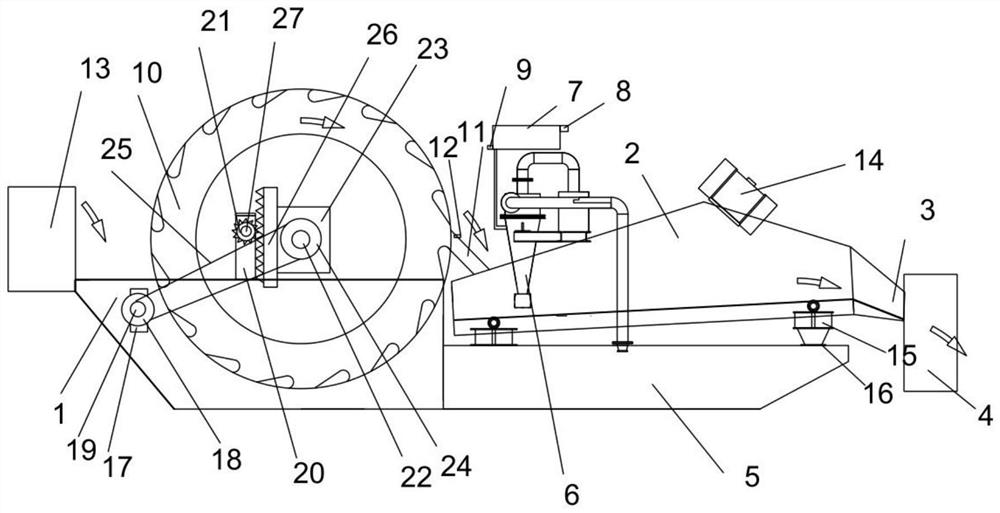

[0040] see image 3 , the present embodiment provides a fully automatic sand washing machine. Further, in order to adjust the distance between the conveying impeller 10 and the bottom of the first water tank as required, a motor bracket 17 is provided on the side of the first water tank 1. On the motor bracket 17 A second motor 18 is provided, and the output of the second motor 18 is connected with a rotating wheel 19. The front and rear side walls of the first water tank 1 are provided with connecting frames 20, and each connecting frame 20 is provided with a rotary connection with Gear 21, the conveying impeller 10 is connected to an impeller support 23 through a rotating shaft 22, one side of the rotating shaft 22 protrudes from the impeller support 23 and is provided with a pulley 24, which is arranged between the pulley 24 and the rotating wheel 19 The detachable belt 25 is provided with a vertical rack 26 meshing with the gear 21 on the impeller support 23, and a third m...

Embodiment 3

[0042] see Figure 4 , the present embodiment provides a fully automatic sand washing machine. Further, to improve the cleaning effect, a silica gel baffle 30 that is offset against the surface of the conveying impeller 10 is provided at the bottom of the first water tank 1. By setting the silica gel baffle 30, when conveying When the impeller 10 rotates, it can rub against the silica gel baffle 30 to finally perform surface friction cleaning on the gravel to further improve the cleaning effect. In order to improve the cleaning effect, the silicon silica gel baffle 30 should not be too soft, nor too hard, or too soft. There is no mutual friction effect, too hard will affect the rotation efficiency of the conveying impeller 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com