Machine-made sand production line

A production line and machine-made sand technology, applied in the direction of solid separation, etc., can solve the problems of complicated operation, troublesome driving operation, increase labor cost and equipment cost, etc., achieve multi-stage continuous sand washing and sand washing effect, and fully guarantee the sand washing effect. , The effect of saving labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] See attached picture.

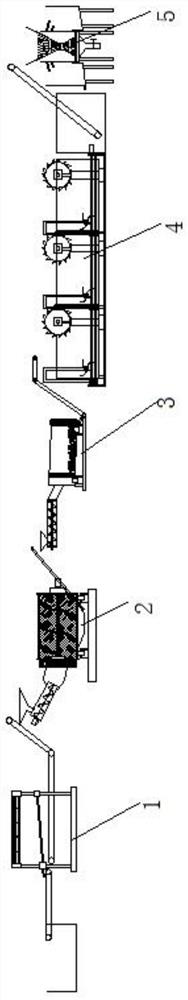

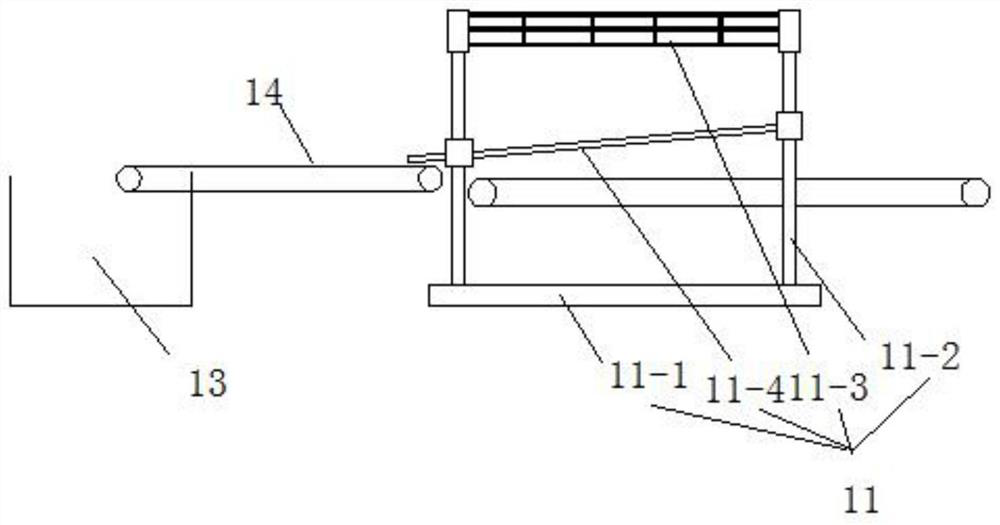

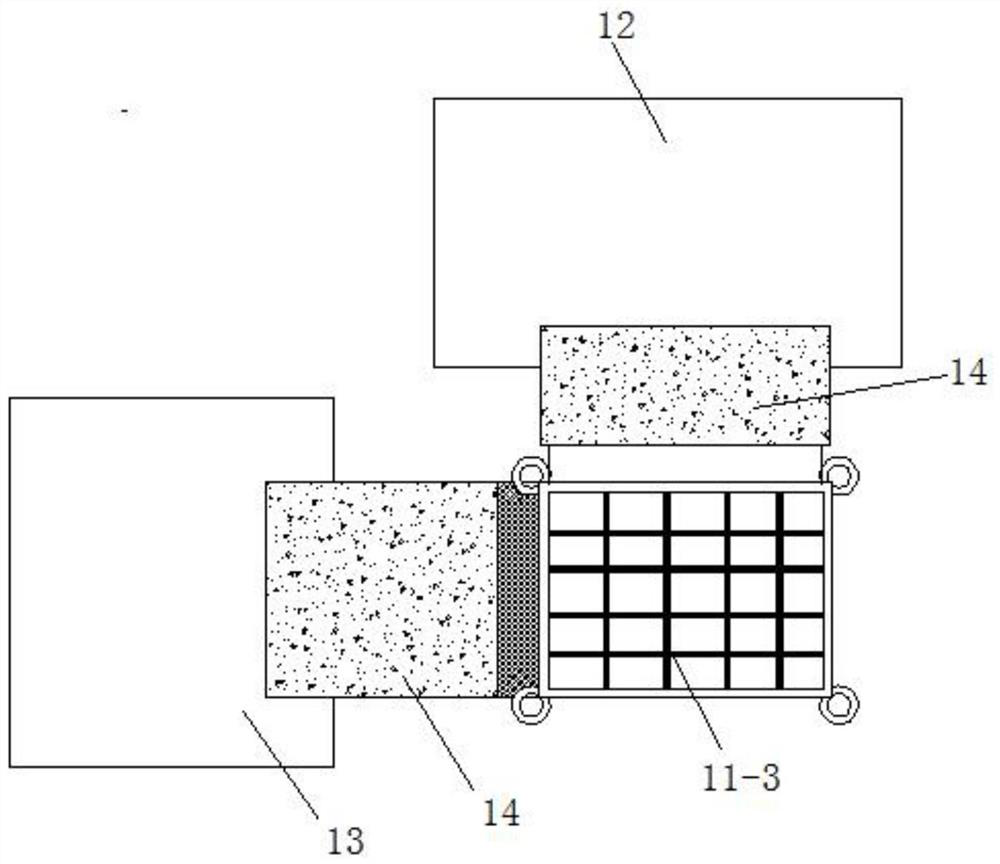

[0032] A machine-made sand production line, including a feeding system 1, a shaftless drum screening system 2, a ball milling system 3, a sand washing system 4, and a concentration and purification system 5 arranged sequentially along the production process. Screening device 11 for direct screening after material, receiving bin 12 for storing large material after screening, buffer bin 13 for buffering small material after screening, and transporting large material and small material to processing respectively The circulation conveying component 14 on the production line, the screening device 11 includes a base 11-1, and a supporting column 11-2 is distributed on the base 11-1, and a large material screening net arranged at an upper and lower intervals and inclined is erected on the supporting column 11-2 11-3 and the vibrating screen 11-4, the bottom end of the vibrating screen 11-4 is set with a fine material circulation conveyor belt 11-5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com