Positioning drilling machine

A drilling machine and chassis technology, applied in boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc., can solve the problems of inaccurate positioning and low processing accuracy, and improve accuracy , improve accuracy, increase resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

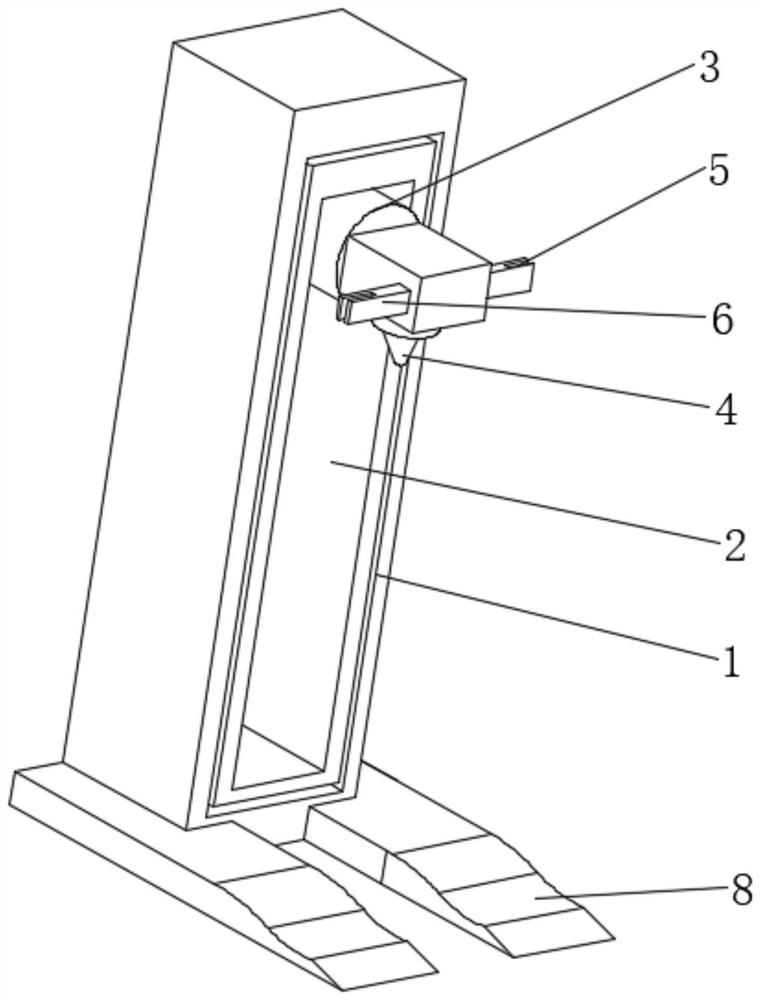

[0029] see figure 1 , the present invention provides a technical solution: a positioning drilling machine, including a chassis 1, the outer surface of the chassis 1 is provided with a sliding groove 2, the inner surface of the sliding groove 2 is slidably connected with a sliding base 3, and the outer surface of the sliding base 3 The drilling head 4 is fixedly connected through the connection block, the left and right sides of the connection block are fixedly connected with the brake plate 5, the outer surface of the brake plate 5 is provided with a U-shaped groove 6, and the inner surface of the U-shaped groove 6 is provided with a touch Mechanism 7, the bottom of the cabinet 1 is fixedly connected with a fixed plate 8, the outer surface of the fixed plate 8 is provided with a bar-shaped groove 9 directly in front of the cabinet 1, and the left and right sides of the inner surface of the bar-shaped groove 9 are provided with dark grooves 10 The inner surface of the dark groo...

Embodiment 2

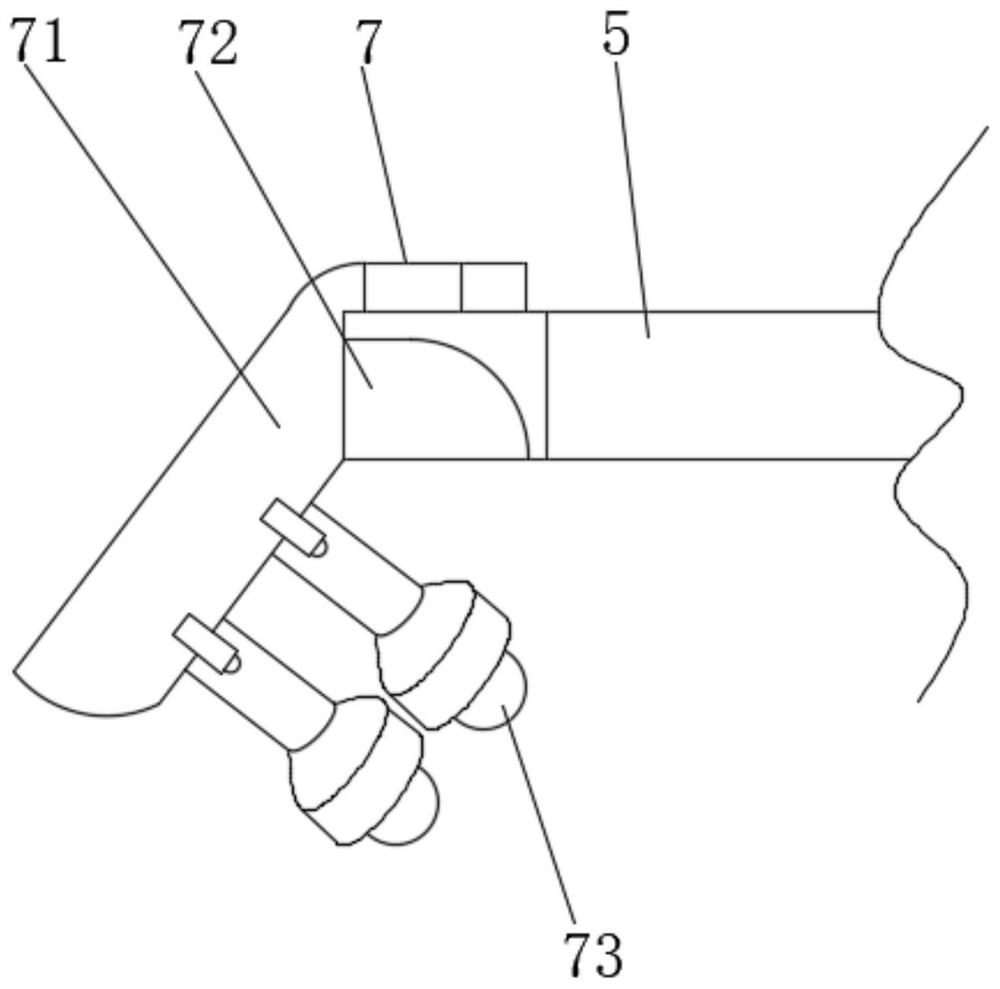

[0031] see Figure 2-3 , the present invention provides a technical solution: the trigger mechanism 7 includes a rotating curved rod 71, the outer surface of the rotating curved rod 71 is rotationally connected with the inner surface of the U-shaped groove 6, and the outer surface of the braking plate 5 is slidably connected with an arc-shaped block 72 , the rear of the arc-shaped block 72 is slidingly connected with the outer surface of the rotating curved rod 71 through the connecting rod, the bottom of the outer surface of the rotating curved rod 71 is fixedly connected with a knocking rod 73 through a spring rod, and the inner surface of the U-shaped groove 6 is provided with an anti-skid Component 74. After the arc-shaped block 72 is pushed, the arc-shaped block 72 moves upwards to leave the inside of the rotating curved rod 71, the rotating curved rod 71 rotates downward with gravity, the knocking rod 73 moves downward, and the trigger mechanism 7 can touch the positioni...

Embodiment 3

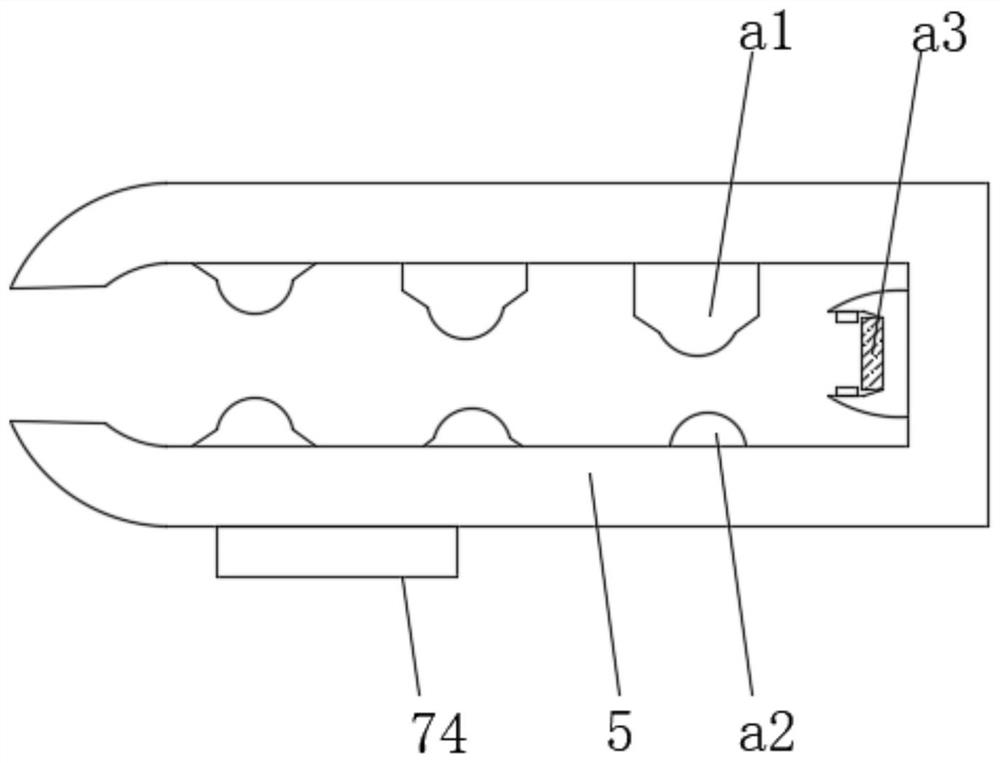

[0035] see Figure 4-6 , the present invention provides a technical solution: the positioning mechanism 11 includes an arc-shaped fixed frame 111, the left and right sides of the outer surface of the arc-shaped fixed frame 111 are respectively fixedly connected with the left and right sides of the inner surface of the strip groove 9, and the inner surface of the dark groove 10 The surface is slidingly connected with a positioning plate 112, the outer surface of the positioning plate 112 is uniformly provided with a circular groove 113, the inner surface of the circular groove 113 is fixedly connected with a positioning belt assembly 114, the outer surface of the positioning plate 112 and the inner surface of the arc-shaped fixed frame 111 Slidingly connected, the left and right sides of the top of the fixed plate 8 are all slidably connected with sliding blocks 115 . After the sliding block moves backward, the positioning plate 112 moves forward to the arc-shaped fixed frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com