Copper pipe port machining, polishing and deburring device

A port and copper tube technology, applied in the field of copper tube port processing, polishing and deburring devices, can solve the problems of not meeting production efficiency requirements, low manual grinding efficiency, inconvenient collection, etc. The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

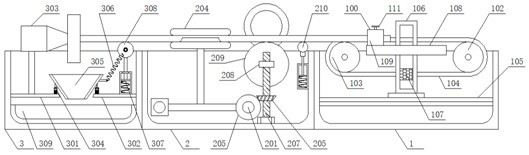

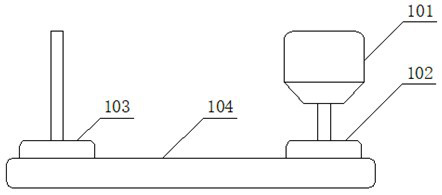

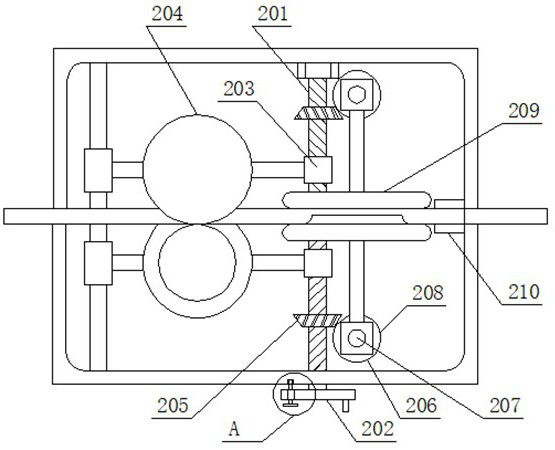

[0031]SeeFigure 1-6The present invention provides a technical solution: a copper-tube port processing polishing destinating device including a transmission cartridge 1, a correction cartridge 2, and a grinding cartridge 3, and the right side of the top of the inner wall of the transmission cartridge 1 is fixed to the right side of the upper portion of the upper side fixed connection. Installation, coaxial layout, output speed 20R / min, output torque 12 kg / cm, voltage 220V transmission motor 101, the front surface of the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com