Handrail surface machining shot blasting machine and shot blasting treatment method

A technology of surface processing and shot blasting machine, which is applied in the direction of metal processing equipment, used abrasive processing devices, manufacturing tools, etc., can solve the problems that the shot blasting quality cannot be guaranteed and the efficiency of the shot blasting machine is low, so as to ensure the shot blasting The effect of processing quality, improving shot blasting efficiency, and ensuring shot blasting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

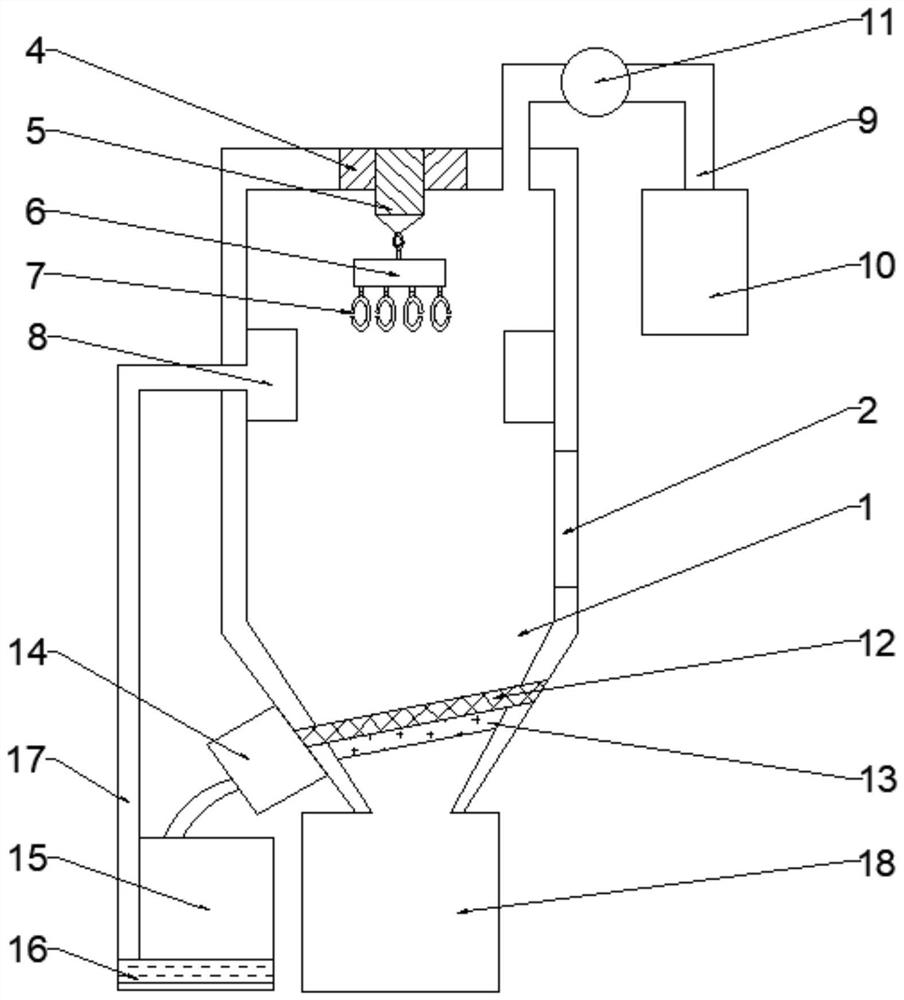

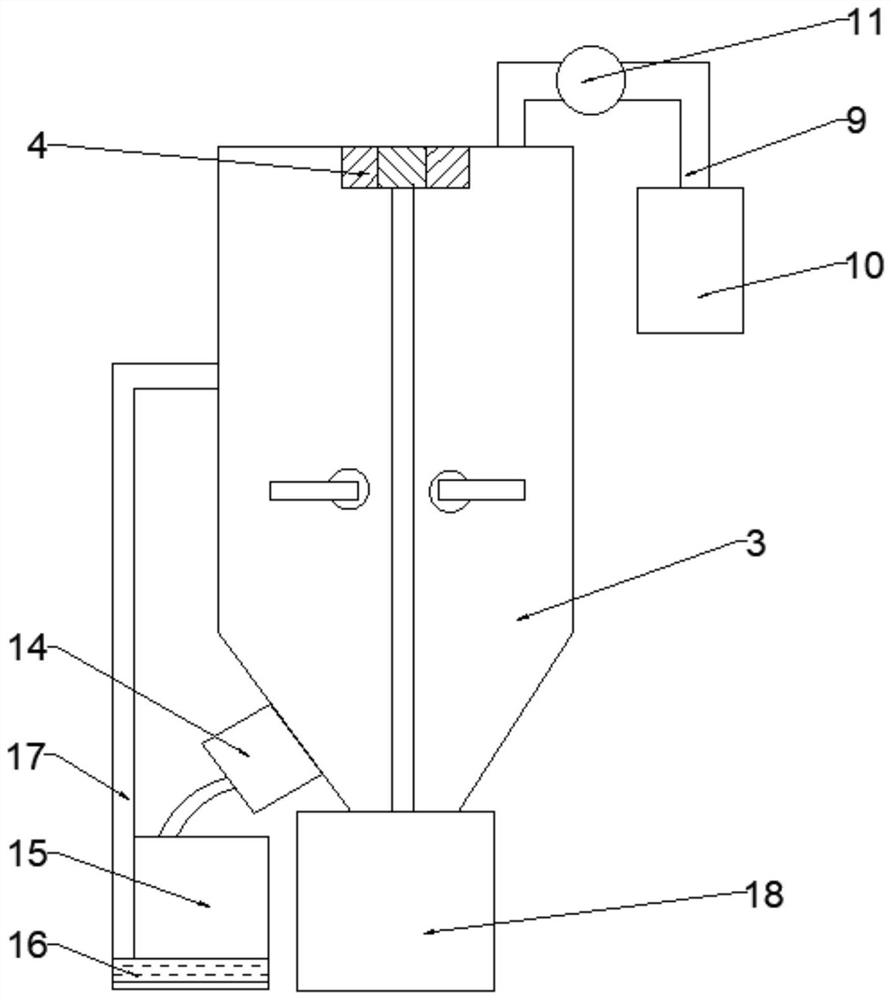

[0023] Such as figure 1 with figure 2 As shown, a railing surface processing shot blasting machine includes a shot blasting chamber 1, the inner wall of the shot blasting chamber 1 is provided with a sound-absorbing layer, the outer wall of the shot blasting chamber 1 is provided with an observation window 2, and one side of the shot blasting chamber 1 is provided with a pneumatic chamber door 3. The pneumatic chamber door 3 is sealed by rubber. The top of the shot blasting chamber 1 is provided with a top frame 4. The top frame 4 is equipped with an electric hoist 5. The bottom of the electric hoist 5 is connected to the suspension plate 6, and the suspension plate 6 is evenly distributed along the circumference. 7. The top of the shot blasting chamber 1 is connected to the dust removal box 10 through the dust removal pipe 9. The dust removal pipe 9 is provided with a dust remover 11, the side wall of the shot blasting chamber 1 is provided with a shot blasting device 8, and...

Embodiment 2

[0025] A method for shot blasting treatment using the shot blasting machine of Embodiment 1, comprising the following steps: hang the railing workpiece to be processed on the hook, slide the electric hoist along the top frame to the shot blasting chamber, close the pneumatic chamber door, At the same time, turn on the shot blasting device, vibrating plate, shot sorting device, screw conveyor, bucket elevator and dust collector, and launch the shot blasting into the shot blasting chamber through the shot blasting device to polish the workpiece. After the workpiece is shot blasted, put the All equipment is closed, the pneumatic door is opened, and the workpiece can be taken out.

[0026] Among them, shot blasting adopts shot blasting with a diameter of 0.6mm, a hardness of HRC60, and a grade of G2; the distance between the shot blasting workpiece and the shot blasting port of the shot blasting machine is 60cm, and the shot blasting speed is 50m / s. The pellet processing time was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com