Facial mask preparation technology and toner facial mask prepared by facial mask preparation technology

A preparation process and mask preparation technology, which is applied in metal processing and other directions, can solve the problems that mask paper cannot be applied in a targeted manner, and the mask cannot be cut into small-area mask paper, etc., and achieves the effect of flexible cutting methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

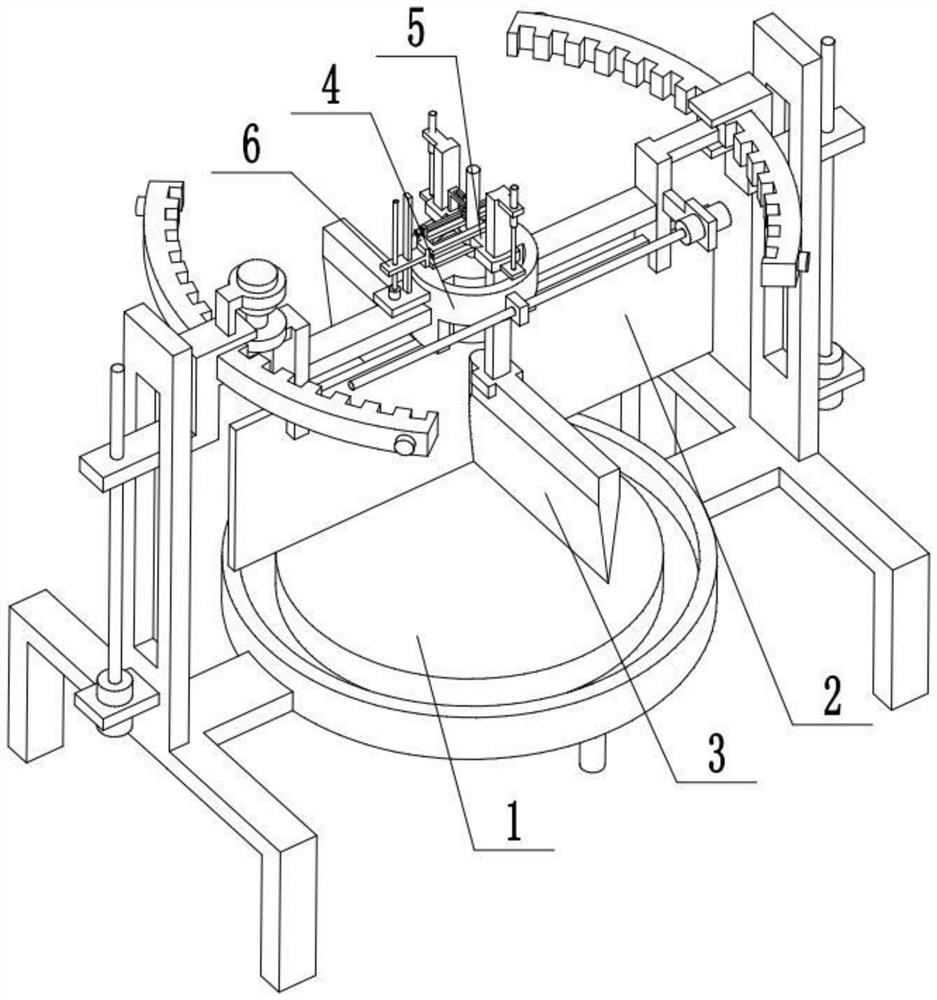

[0037] Combine below Figure 1-9 Illustrate this embodiment, a kind of preparation technology of skin-toning facial mask, comprises the following steps:

[0038] Step 1. Lay the mask paper on a flat surface;

[0039] Step 2. The cutter moves down to cut the mask paper, and divides the whole mask paper into small parts;

[0040] Step 3. Adjust the position of the cutter and cut the mask paper into small portions of different sizes;

[0041] Step 4. Adjust the angle of the cutter to cut the mask paper from different angles;

[0042] In the preparation process of the above-mentioned skin-toning facial mask, a skin-toning facial mask preparation system is also involved;

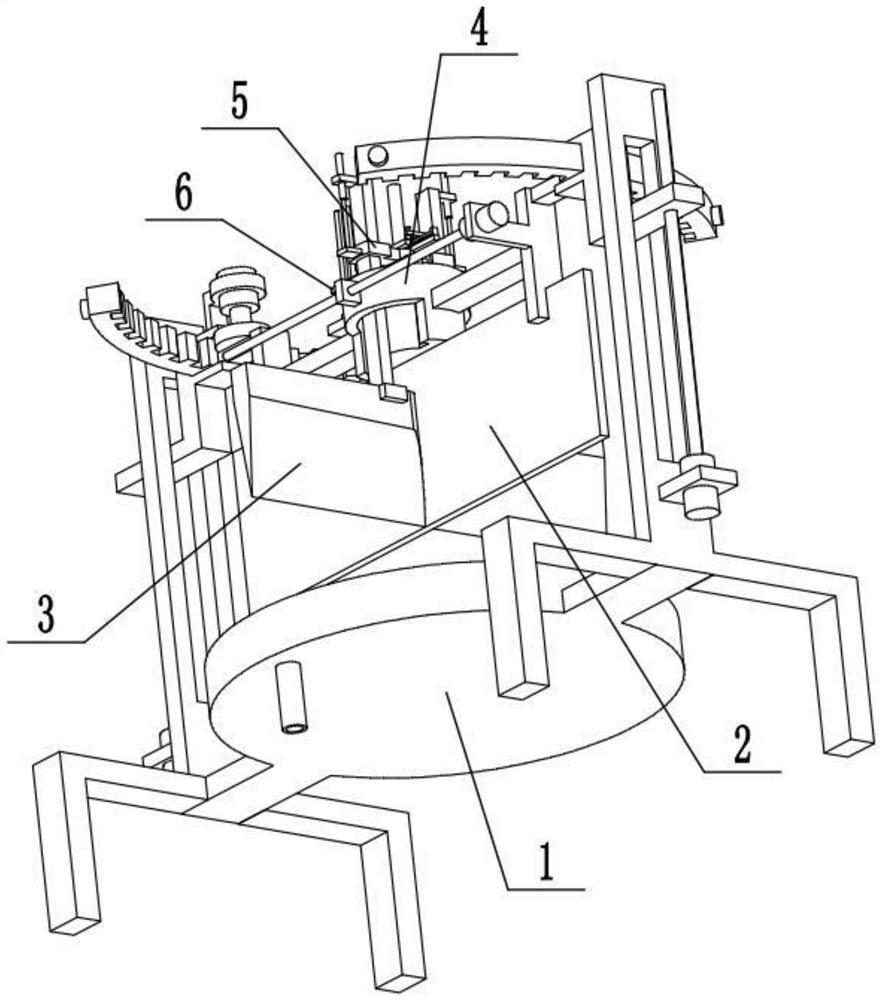

[0043]The skin-toning facial mask preparation system includes a placement frame 1, a groove frame 1-2, a motor one 1-3, a lead screw one 1-4, a Z-shaped plate 1-5, a horizontal cutter 2 and a vertical cutter 3, place The two ends of the frame 1 are respectively fixedly connected with a grooved frame 1-2, and ...

specific Embodiment approach 2

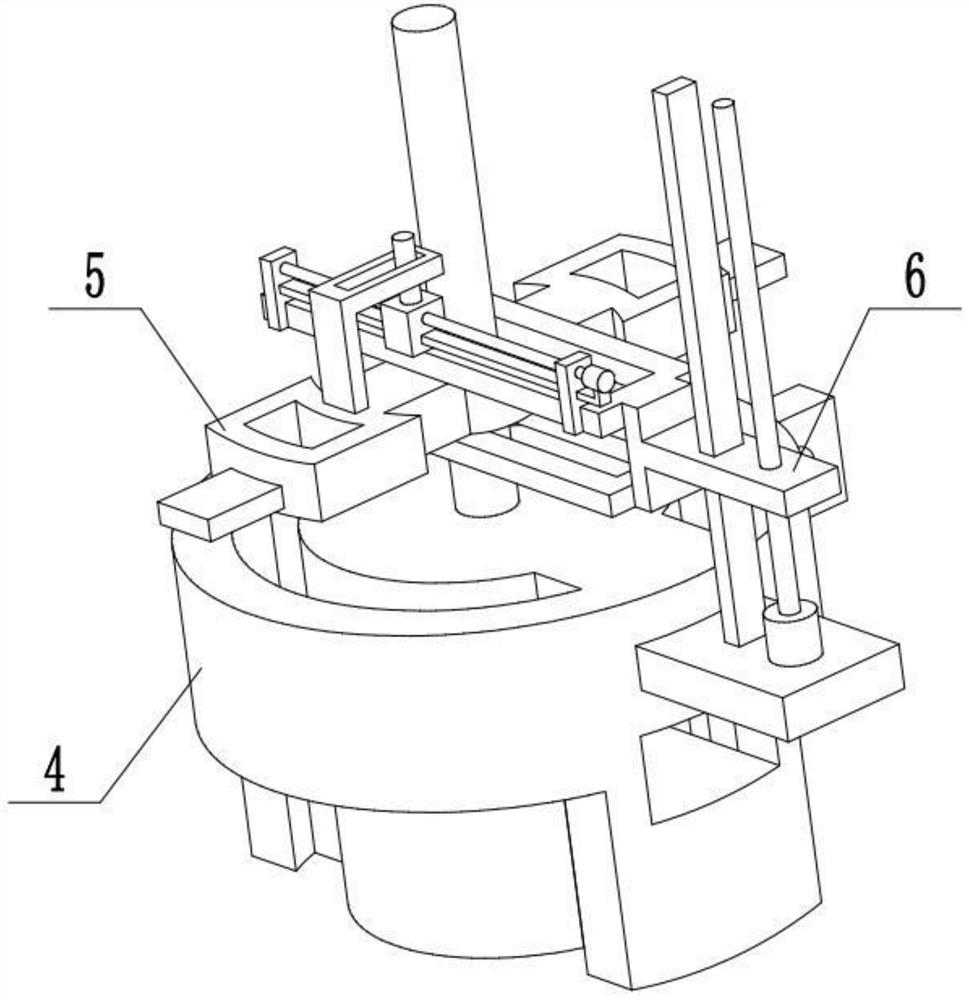

[0045] Combine below Figure 1-9 Illustrate this embodiment mode, described a kind of toner facial mask preparation system also comprises arc groove 1-6, motor two 1-7, gear 1-8, side frame 2-1 and arc rack 2-2, horizontal The upper end of the cutter 2 is fixedly connected to two side frames 2-1, the outer ends of the two side frames 2-1 are respectively fixedly connected to an arc-shaped rack 2-2, and the inner ends of the two Z-shaped plates 1-5 are respectively set There is an arc-shaped slot 1-6, two arc-shaped racks 2-2 are slidably connected in the two arc-shaped slots 1-6, the motor two 1-7 is fixedly connected on a Z-shaped plate 1-5, and the motor The output shaft of two 1-7 is fixedly connected with the gear 1-8, and the gear 1-8 is meshed with an arc rack 2-2 for transmission connection. The motor 2 1-7 starts to drive the corresponding arc rack 2-2 to rotate through the gear 1-8, and the arc rack 2-2 drives the horizontal cutter 2 and two longitudinal cutters 3 ar...

specific Embodiment approach 3

[0047] Combine below Figure 1-9 Illustrate this embodiment mode, described a kind of toner facial mask preparation system also comprises cross bar 2-3, motor three 2-4 and lead screw two 2-5, smooth seat 4 and bump 4-3, two side frames 2-1 is fixedly connected to the cross bar 2-3, and the smooth seat 4 is slidably connected to the cross bar 2-3. Block 4-3, bump 4-3 is meshed with lead screw 2-5 for transmission connection, lead screw 2 2-5 is fixedly connected to the output shaft of motor 3 2-4, motor 3 2-4 is fixedly connected to a Z Pattern 1-5 on. The motor 3 2-4 starts to drive the screw 2 2-5 to rotate, the screw 2 2-5 drives the smooth seat 4 to slide left and right on the cross bar 2-3 through the bump 4-3, and the smooth seat 4 drives two longitudinal cutters 3 moves left and right, the positions of the two vertical cutters 3 relative to the horizontal cutter 2 change, and the mask paper cut out on the left and right sides of the vertical cutter 3 is not symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com