Preparation method of building terrain model and hot melt cutting device used therefor

A terrain model and building technology, which is applied in the field of building model production, can solve the problems of high cost, inaccuracy, and difficulty in printing large-scale solid models, and achieve the effects of low production cost, simple production method and flexible cutting method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] A method for preparing a building terrain model, comprising the steps of:

[0041] A) Use computer-aided design software to simplify the points on the circular curve of the topographic elevation map without changing the topographic structure of the topographic elevation map, reduce the appearance accuracy of the terrain, and make the transition between the points forming the circular curve smooth and form a transition smooth circular curves;

[0042] B) supplement the unclosed part of the circular curve with smooth transition obtained in step A) to form a closed plane, and select the vertically upward parts of the circular curve one by one to stake out and fuse them into a three-dimensional model;

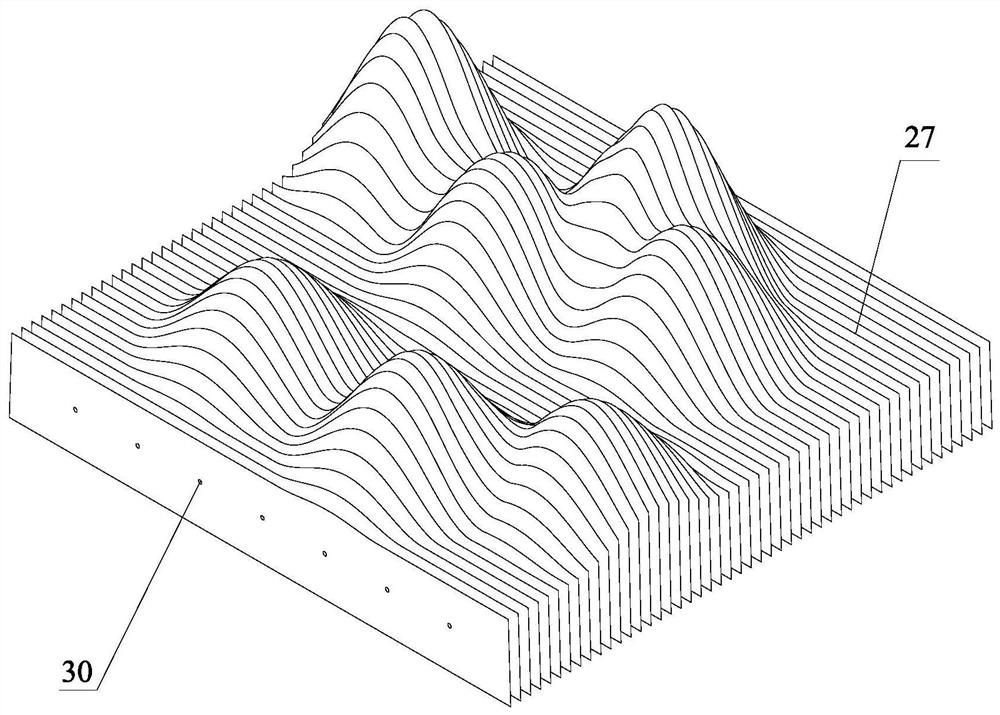

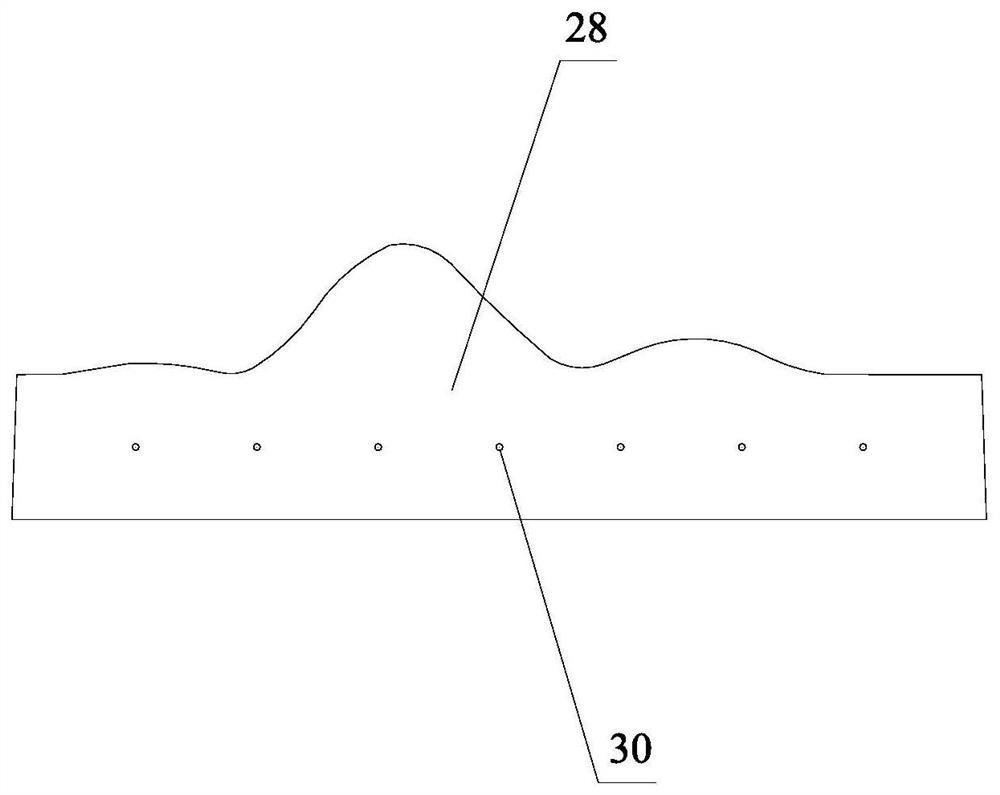

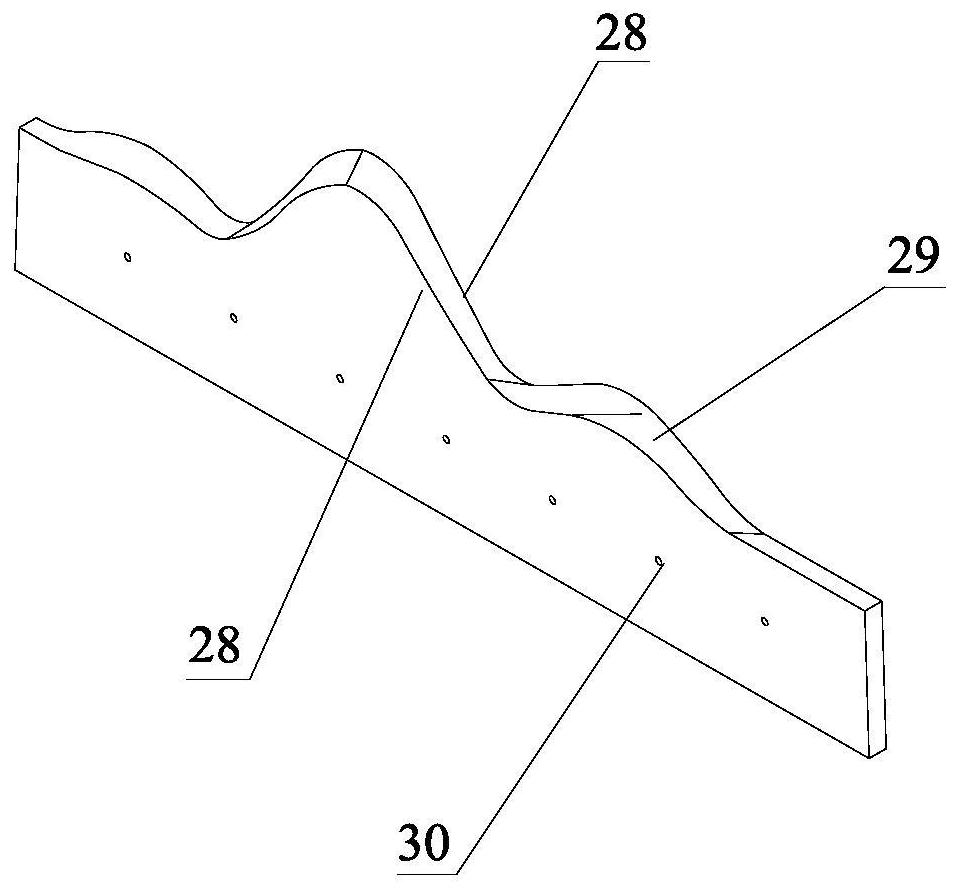

[0043] C) scale the three-dimensional model obtained in step B) into the size that needs to be made by entity, such as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com