Wooden basket batch automatic trimming device

A batch, trimming technology, used in wood processing appliances, special forming/shaping machines, manufacturing tools, etc., can solve the problems of clean removal of residual bamboo pieces, equipment failure, damaged wooden baskets, etc., to save the time of feeding and collection time, improve efficiency, fast push and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

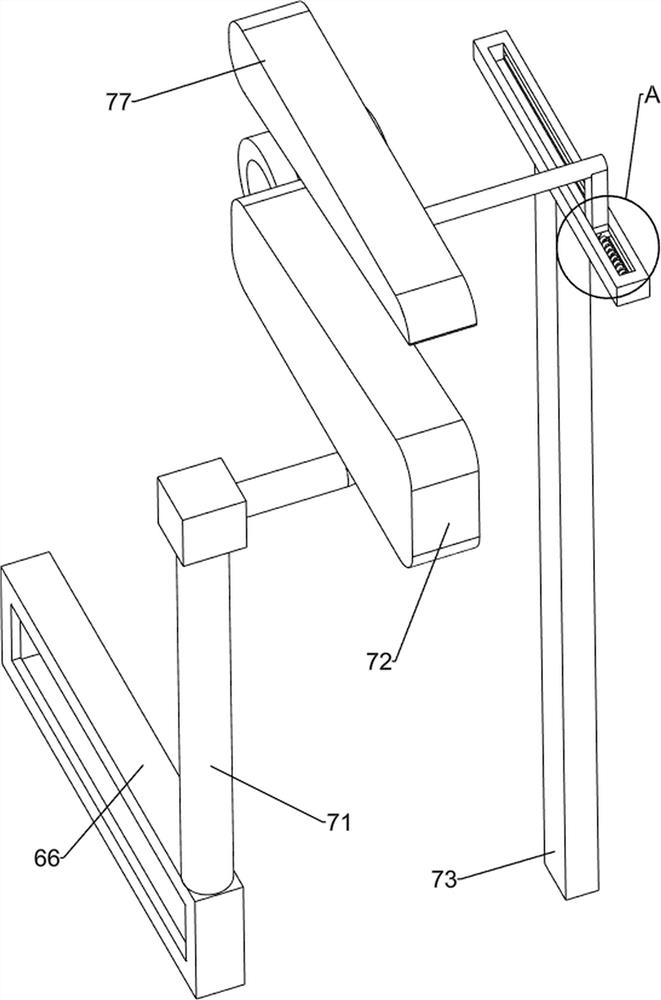

[0023] A wooden basket batch automatic trimming device, such as figure 1 As shown, it includes a base plate 1, a first support column 2, a motor 3, a rotating mechanism 4 and a cutting mechanism 5, the right side of the base plate 1 is provided with a first support column 2, the first support column 2 is provided with a motor 3, and the motor 3 A rotating mechanism 4 is connected with the bottom plate 1, and a cutting mechanism 5 is provided on the left side of the bottom plate 1.

[0024] When people need to trim the wooden basket, the wooden basket is placed on the rotating mechanism 4, then the motor 3 is started, the motor 3 drives the rotating mechanism 4 to rotate, and the cutting mechanism 5 starts to move at the same time, and the wooden basket is trimmed. After the limit finishes, close motor 3, make rotating mechanism 4 and cutting mechanism 5 stop moving, at this moment wooden basket can be taken off.

Embodiment 2

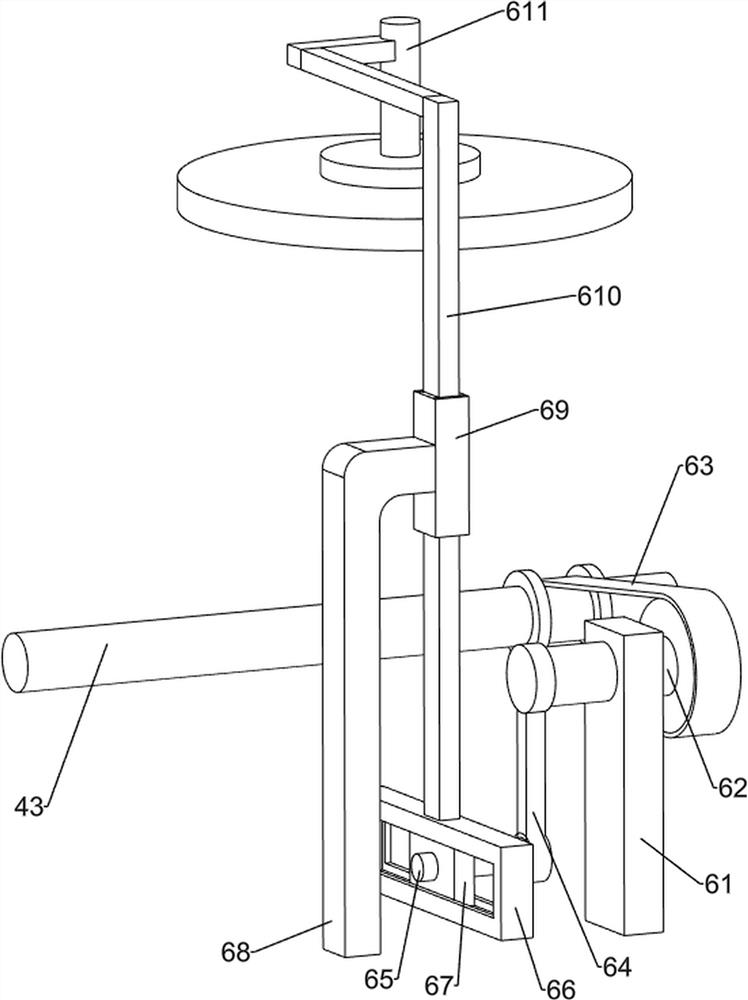

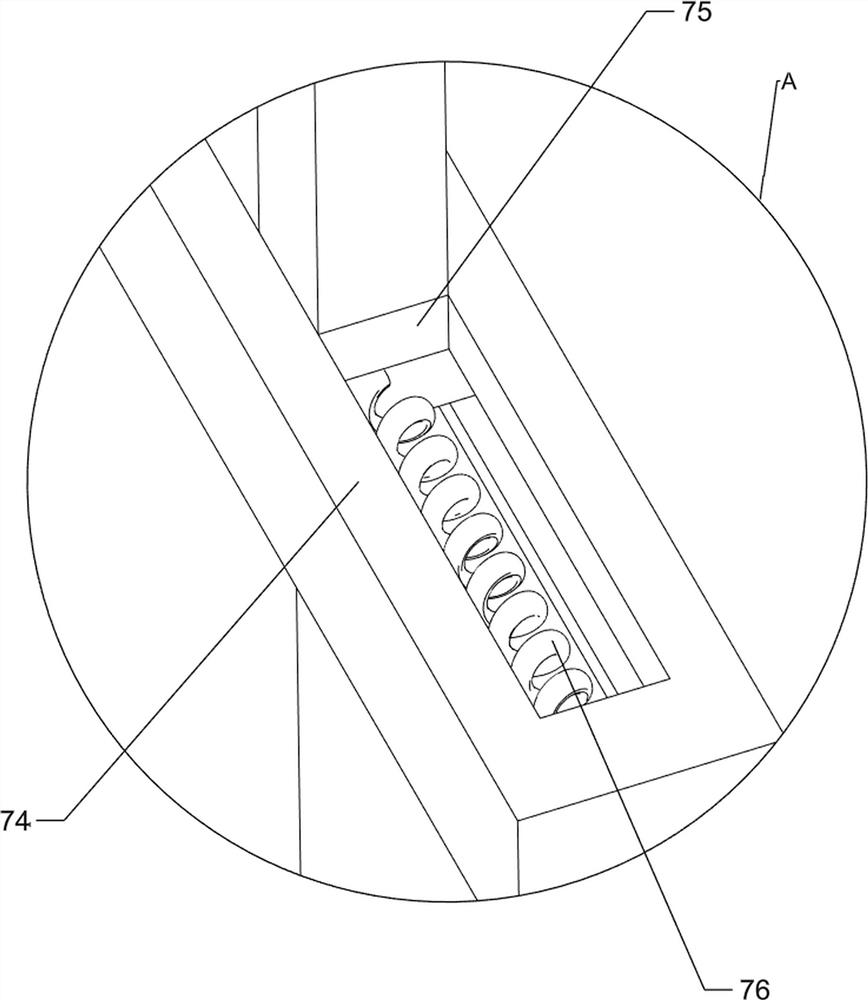

[0026] On the basis of Example 1, such as Figure 2 to Figure 7 As shown, the rotating mechanism 4 includes a second support column 41, a first rotating shaft 42, a second rotating shaft 43, a first transmission assembly 44, a first bevel gear set 45, a rotating disk 46 and a fixed support rod 451, and the left side of the motor 3 is provided There is a first rotating shaft 42, and the left part of the bottom plate 1 is provided with a second support column 41, on which the second supporting column 41 is rotatably connected with a second rotating shaft 43, and between the right side of the second rotating shaft 43 and the first rotating shaft 42 is connected a first The transmission assembly 44 is provided with a first bevel gear set 45 in the middle of the second rotating shaft 43, and a fixed support rod 451 is provided at the right part of the bottom plate 1. The fixed support rod 451 is rotatably connected with a turntable 46. Connected, the lower part of the rotating disk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com