Preparation method and application of soluble soybean polysaccharide for stabilizing acidic whey protein beverage

A soybean polysaccharide and acid milk technology, applied in the field of food additives, can solve the problems of limiting the practical application of whey protein beverages, easy turbidity, poor thermal stability of whey protein, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

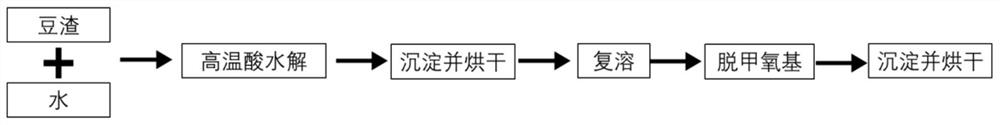

Method used

Image

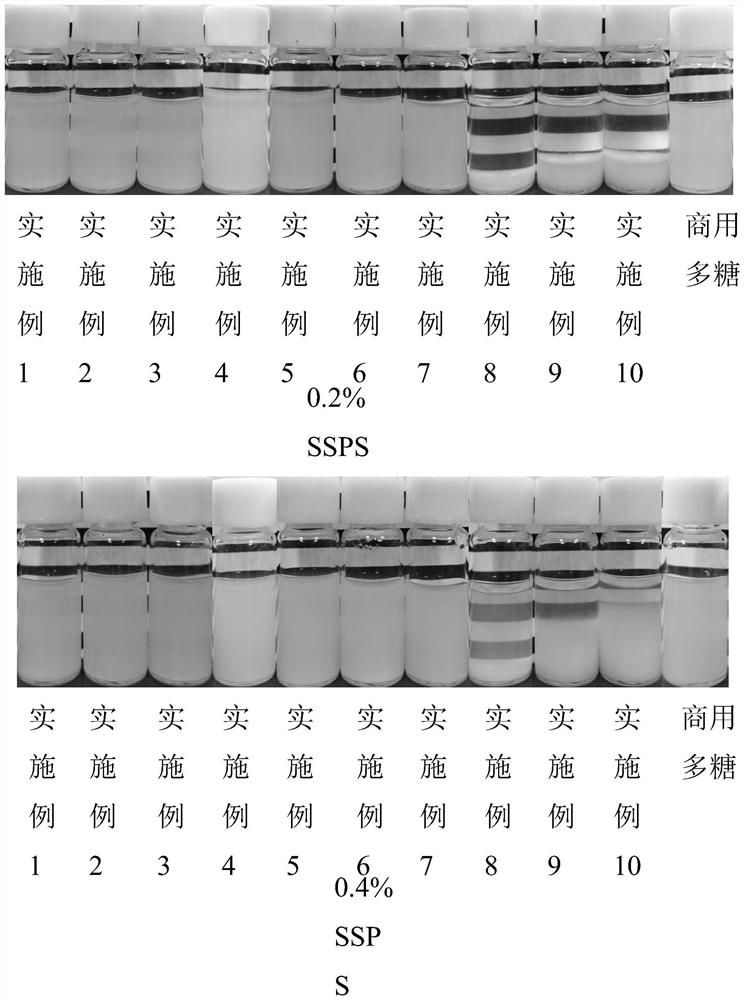

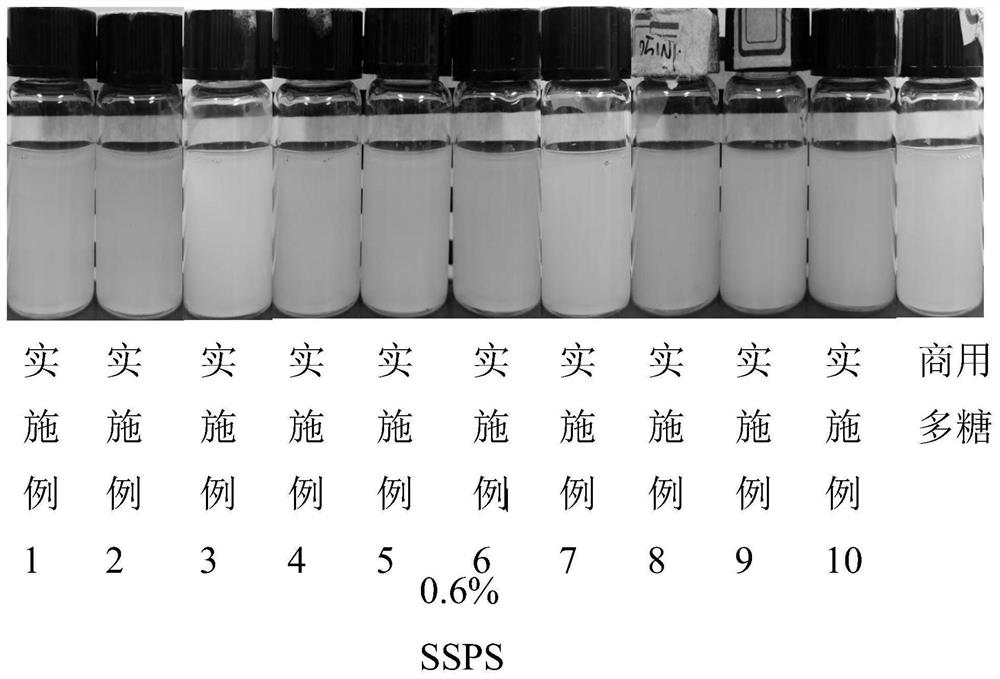

Examples

Embodiment 1

[0028] Take 10g of dried bean dregs, prepare a suspension according to the ratio of material to liquid 1:30, add hydrochloric acid for high-temperature acid hydrolysis, control the pH to 4, the temperature is 100°C, and the reaction time is 2h. After the reaction is completed, centrifuge at 4000rpm to obtain the supernatant. The supernatant obtained in the step was adjusted to pH 7.0 with sodium hydroxide, and the supernatant was mixed with ethanol at a volume ratio of 1:3, centrifuged at 4000 rpm, and the precipitate was oven-dried at 45°C for 12 hours to obtain soluble soybean polysaccharide. Dissolve the soluble soybean polysaccharide: the ratio of water to liquid is 1:10, and the reaction time is 2h. After the reaction, the solution was adjusted to pH 7.0 with hydrochloric acid, mixed with ethanol at a volume ratio of 1:3, centrifuged at 4000 rpm, and dried in an oven at 45°C for 12 hours to obtain soluble soybean polysaccharide.

Embodiment 2

[0030] Take 10g of dried bean dregs, prepare a suspension according to the ratio of material to liquid 1:30, add hydrochloric acid for high-temperature acid hydrolysis, control the pH to 4, the temperature is 100°C, and the reaction time is 2h. After the reaction is completed, centrifuge at 4000rpm to obtain the supernatant. The supernatant obtained in the step was adjusted to pH 7.0 with sodium hydroxide, and the supernatant was mixed with ethanol at a volume ratio of 1:3, centrifuged at 4000 rpm, and the precipitate was oven-dried at 45°C for 12 hours to obtain soluble soybean polysaccharide. Dissolve the soluble soybean polysaccharide: the ratio of water to liquid is 1:10, add sodium hydroxide to adjust the pH to 12, control the temperature to 90°C, and the reaction time is 2h. After the reaction, the solution was adjusted to pH 7.0 with hydrochloric acid, mixed with ethanol at a volume ratio of 1:3, centrifuged at 4000 rpm, and dried in an oven at 45°C for 12 hours to obtai...

Embodiment 3

[0032] Take 10g of dried bean dregs, prepare a suspension according to the ratio of material to liquid 1:30, add hydrochloric acid for high-temperature acid hydrolysis, control the pH to 4, the temperature is 100°C, and the reaction time is 2h. After the reaction is completed, centrifuge at 4000rpm to obtain the supernatant. The supernatant obtained in the step was adjusted to pH 7.0 with sodium hydroxide, and the supernatant was mixed with ethanol at a volume ratio of 1:3, centrifuged at 4000 rpm, and the precipitate was oven-dried at 45°C for 12 hours to obtain soluble soybean polysaccharide. Dissolve the soluble soybean polysaccharide: the ratio of water to liquid is 1:10, add sodium hydroxide to adjust the pH to 13, control the temperature to 90°C, and the reaction time is 2h. After the reaction, the solution was adjusted to pH 7.0 with hydrochloric acid, mixed with ethanol at a volume ratio of 1:3, centrifuged at 4000 rpm, and dried in an oven at 45°C for 12 hours to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com