Preparation method of polyisobutylene maleic anhydride

A technology of polyisobutylene and maleic anhydride, applied in the field of lubricating oil additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

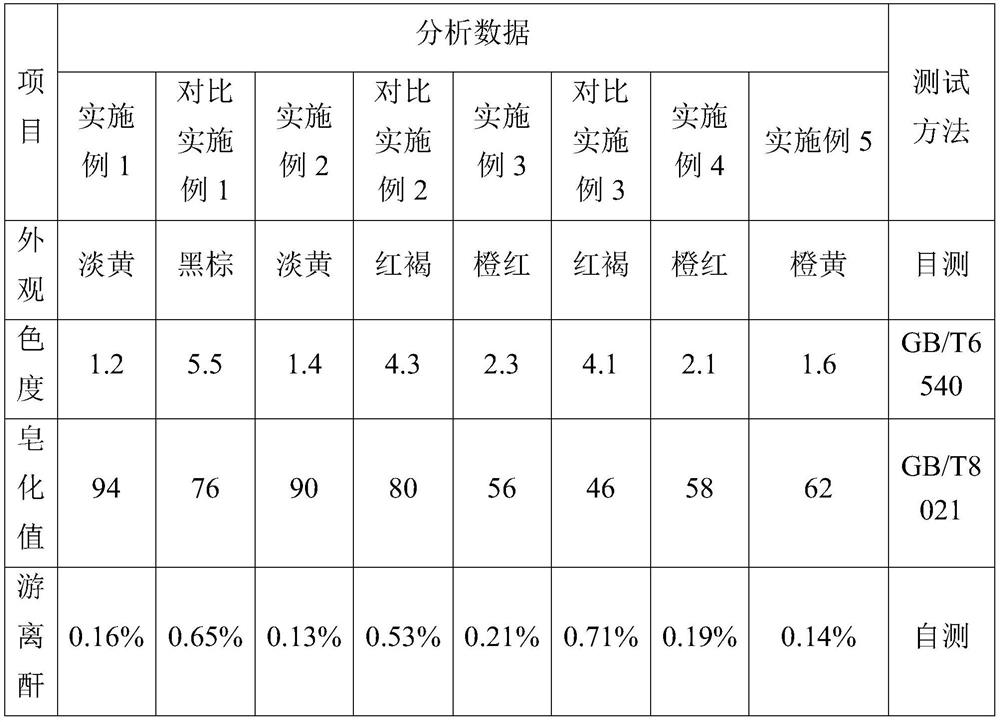

Examples

Embodiment 1

[0062] (1) Add Jihua high-activity polyisobutylene PIB-1000 (200g) into the pressure-resistant reactor, then start stirring and temperature control, gradually raise the temperature to the reaction temperature to 210°C, and feed a large amount of N into the reactor 2 Purge the air in the replacement reactor, then seal the reactor and continue to feed N 2 Make the inside of the reactor in a "slightly positive pressure" state of 0.5MPa.

[0063] (2) Heat 25.5g of maleic anhydride (the molar ratio of polyisobutylene to maleic anhydride is 1:1.3) to 70°C to make it in a molten state, and then feed the molten maleic anhydride to step (1) through a booster pump The reactor was continuously added dropwise for 3 hours, and the reaction was continued for 10 hours by maintaining a "micro positive pressure" of 0.5 MPa after the dropwise addition was completed.

[0064] (3) After the reaction is completed, the temperature is lowered to 180°C, the pressure in the reactor is released to nor...

Embodiment 2

[0068] (1) Add Yangzi BASF high-activity polyisobutylene PIB-1300 (200g) into the pressure-resistant reactor, then start stirring and temperature control, gradually raise the temperature to the reaction temperature to 215°C, and feed a large amount of N into the reactor 2 Purge the air in the replacement reactor, then seal the reactor and continue to feed N 2 Make the inside of the reactor in a "slightly positive pressure" state of 1.2MPa.

[0069] (2) Heat 21.1g of maleic anhydride (the molar ratio of polyisobutylene to maleic anhydride is 1:1.4) to 70°C to make it in a molten state, and then feed the molten maleic anhydride to step (1) through a booster pump The reactor was continuously added dropwise for 5 hours, and after the dropwise addition was completed, a "micro positive pressure" of 1.2 MPa was maintained to continue the reaction for 8 hours.

[0070] (3) After the reaction is completed, the temperature is lowered to 180°C, the pressure in the reactor is released to...

Embodiment 3

[0074] (1) Add Jihua high-activity polyisobutylene PIB-2300 (200g) into the pressure-resistant reactor, then start stirring and temperature control, gradually raise the temperature to the reaction temperature to 220°C, and feed a large amount of N into the reactor 2 Purge the air in the replacement reactor, then seal the reactor and continue to feed N 2 Make the inside of the reactor in a "slightly positive pressure" state of 0.8MPa.

[0075] (2) Heat 11.1g of maleic anhydride (the molar ratio of polyisobutylene to maleic anhydride is 1:1.3) to 70°C to make it in a molten state, and then feed the molten maleic anhydride to step (1) through a booster pump The reactor was continuously added dropwise for 7 hours, and after the dropwise addition was completed, 0.8 MPa "micro positive pressure" was maintained to continue the reaction for 4 hours.

[0076] (3) After the reaction is completed, the temperature is lowered to 180°C, the pressure in the reactor is released to normal pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com