Water-soluble boiled tung oil environment-friendly asphalt separant

A cooked tung oil and water-soluble technology, applied in the field of asphalt release agent, can solve the problems of unsafe use, unenvironmental protection and high cost of asphalt release agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

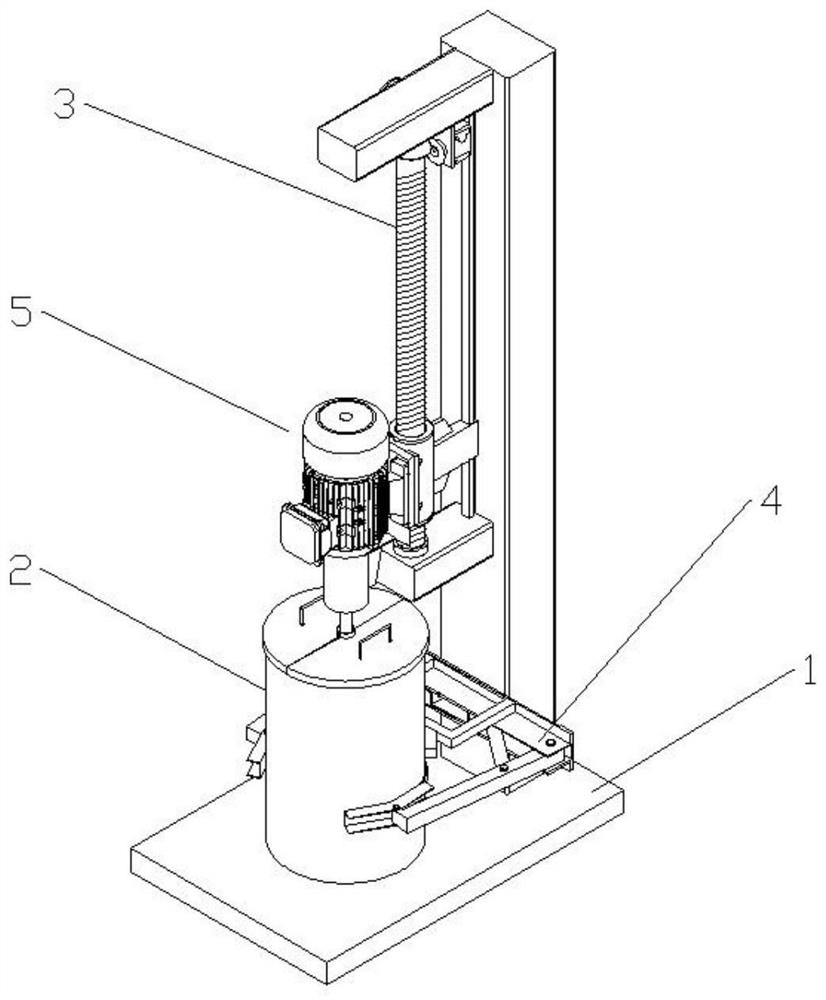

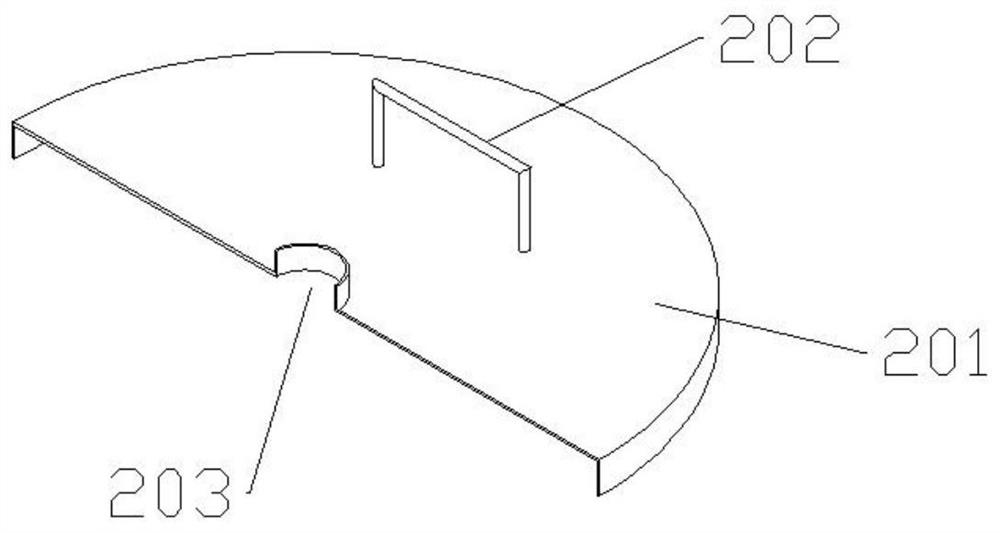

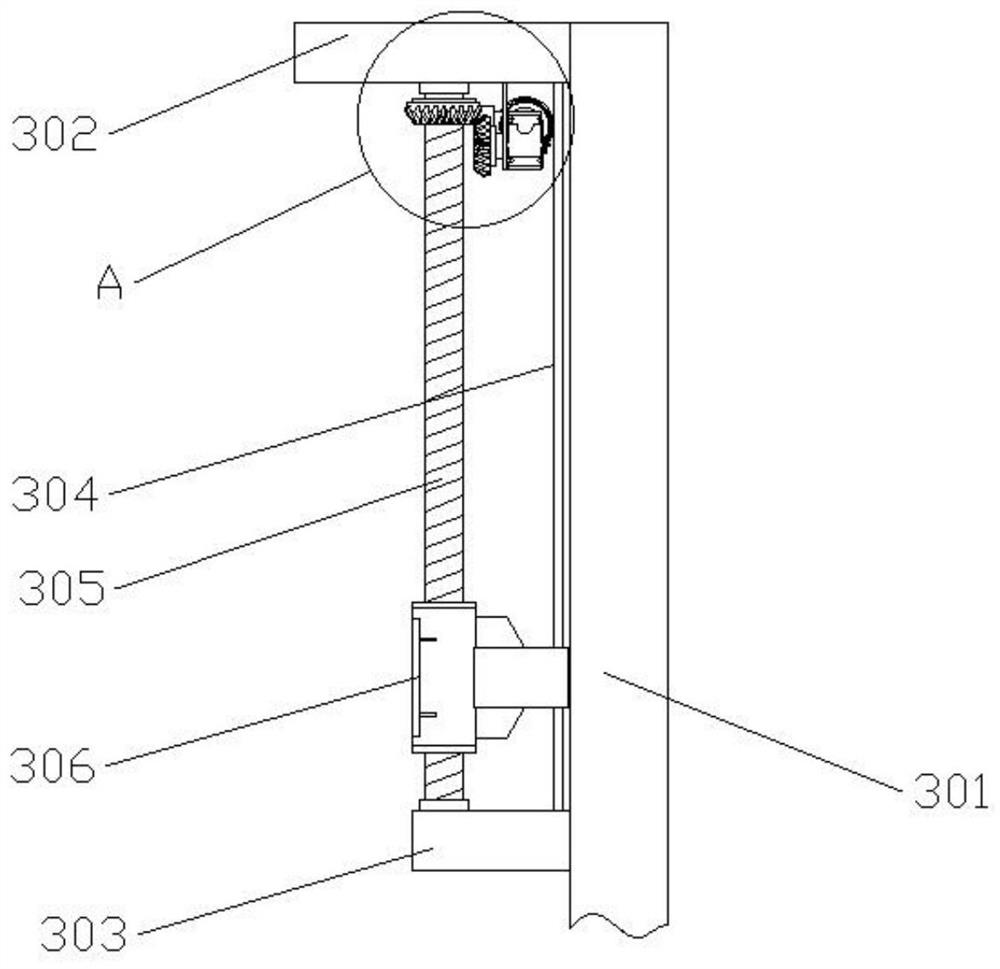

Image

Examples

Embodiment 1

[0031]A water-soluble cooked tung oil environmental protection asphalt release agent, comprising the following raw materials in parts by weight: 3 parts of cooked tung oil, 8 parts of kelp extract, 0.2 part of polyethylene glycol 200, 4 parts of Pingpingjia, 1 part of sodium nitrilotriacetate, 0.1 part gelatin, 8 parts deionized water;

[0032] The preparation method of this kind of water-soluble cooked tung oil environment-friendly asphalt release agent specifically comprises the following steps:

[0033] Step S1: Fully mix the kelp extract and sodium nitrilotriacetate in dry conditions, then add half the weight of the formula in deionized water, and stir and mix evenly at a temperature of 60°C to obtain a composite Stabilizer, heat preservation spare;

[0034] Step S2: Stir and mix the Pingpingjia and gelatin in parts by weight of the formula for 10 minutes at a temperature of 60°C to prepare a surfactant, add the surfactant to the deionized water of the other half by weigh...

Embodiment 2

[0038] A water-soluble cooked tung oil environment-friendly asphalt release agent, comprising the following raw materials in parts by weight: 4 parts of cooked tung oil, 9 parts of kelp extract, 0.4 part of polyethylene glycol 200, 5 parts of Pingpingjia, 2 parts of sodium nitrilotriacetate, 0.2 part gelatin, 9 parts deionized water;

[0039] The preparation method of this kind of water-soluble cooked tung oil environment-friendly asphalt release agent specifically comprises the following steps:

[0040] Step S1: Fully mix the kelp extract and sodium nitrilotriacetate in dry conditions, then add half the weight of the formula in deionized water, and stir and mix evenly at a temperature of 62°C to obtain a composite Stabilizer, heat preservation spare;

[0041] Step S2: Stir and mix the Pingpingjia and gelatin by weight of the formula at 70°C for 15 minutes to prepare a surfactant, add the surfactant to the deionized water of the other half by weight of the formula, and add po...

Embodiment 3

[0045] A water-soluble cooked tung oil environment-friendly asphalt release agent, comprising the following raw materials in parts by weight: 5 parts of cooked tung oil, 10 parts of kelp extract, 0.5 part of polyethylene glycol 200, 6 parts of Pingpingjia, 3 parts of sodium nitrilotriacetate, 0.3 part gelatin, 10 parts deionized water;

[0046] The preparation method of this kind of water-soluble cooked tung oil environment-friendly asphalt release agent specifically comprises the following steps:

[0047] Step S1: Fully mix the kelp extract and sodium nitrilotriacetate in dry conditions, then add half the weight of the formula in deionized water, and stir and mix evenly at a temperature of 65°C to obtain a composite Stabilizer, heat preservation spare;

[0048] Step S2: Stir and mix the formula Pingpingjia and gelatin at a temperature of 80°C for 20 minutes to prepare a surfactant, add the surfactant to the other half of the formula weight part of deionized water, and add po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com