Adhesive applying fabric, setting fabric, processing equipment and processing method

A processing equipment and adhesive tape technology, applied in adhesives, non-woven fabrics, filament/thread forming, etc., can solve the problems of poor air permeability, poor comfort, and poor air permeability of fabrics, and achieve a high degree of automation, improve fluidity, and improve The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

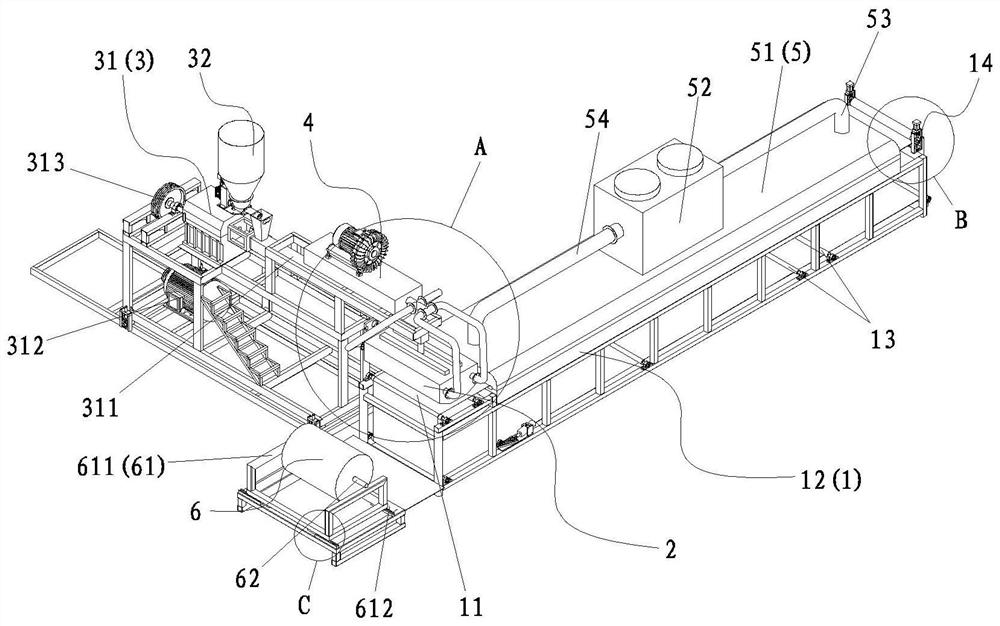

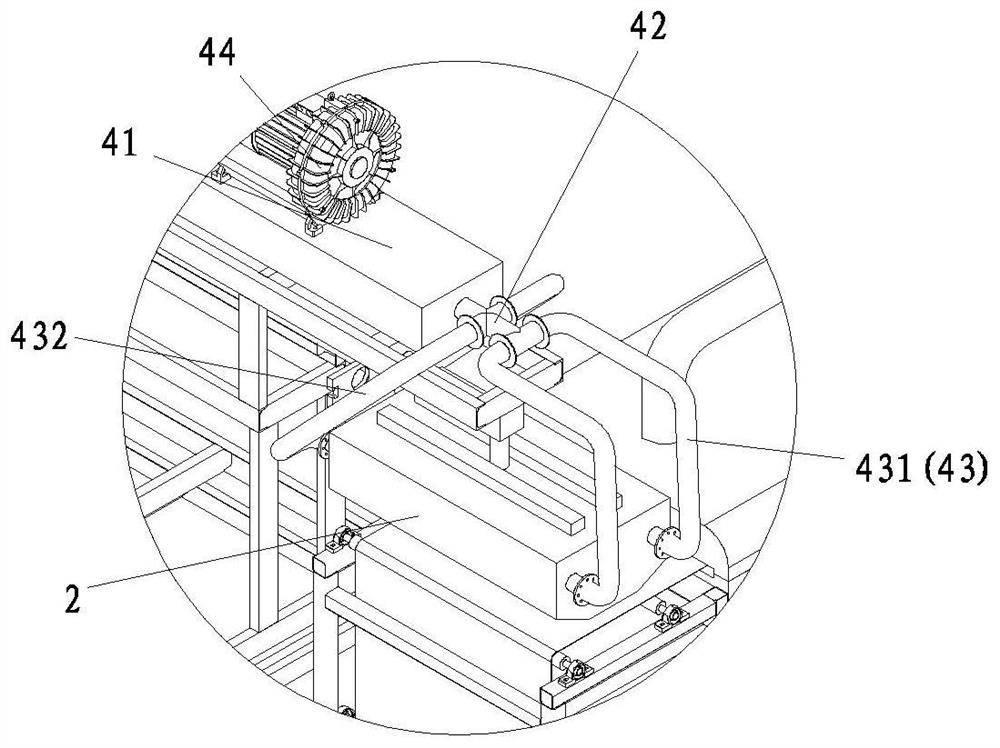

[0065] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

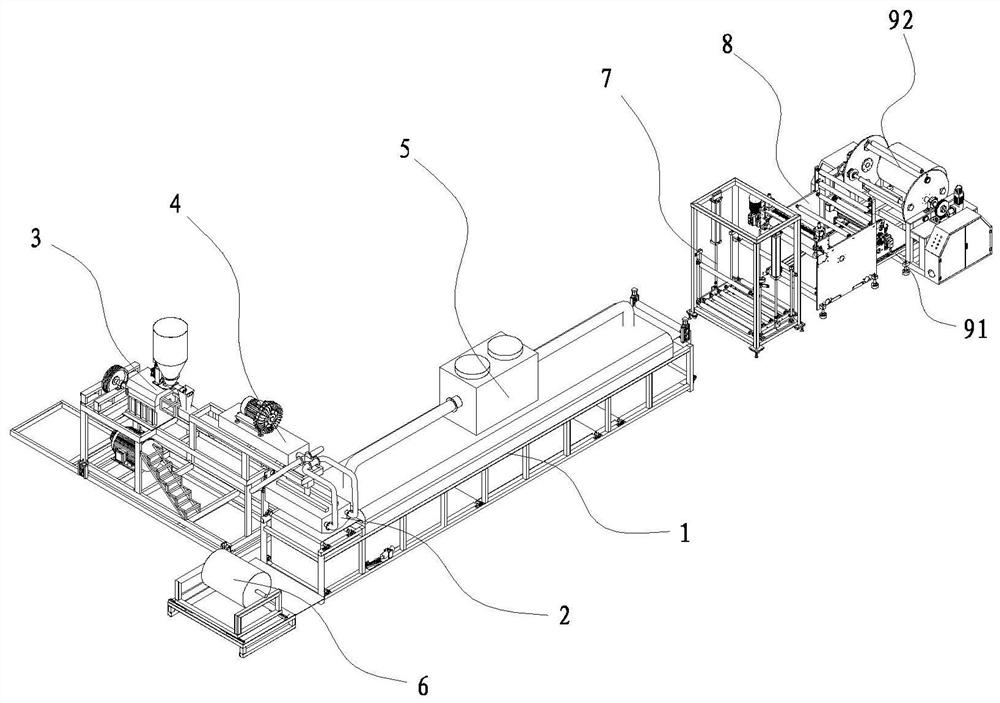

[0066] Such as Figure 1-4 As shown, a sizing cloth includes a base fabric layer and a glue layer covering the surface of the base fabric layer, wherein the glue layer includes interlaced glue threads and air holes formed between the glue threads.

[0067] Preferably, the glue thread is sprayed in a molten state and adhered to the base cloth layer.

[0068] Preferably, the air holes are hollow holes formed by interlacing glue threads.

[0069] Preferably, the vent hole runs through the thickness direction of the adhesive layer. With this structure, the air holes can penetrate through the adhesive layer and extend to the surface of the base fabric layer and the auxiliary fabric, so that the ventilation effect between the base fabric layer and the auxiliary fabric is better.

[0070] Preferably, an auxiliary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com