Overhead portable conversion device for steel structure storage yard and assembly site

A conversion device and steel structure technology, applied to roads, special pavements, roads, etc., can solve the problems of artificial materials and time waste, and achieve the effect of efficiently transmitting loads and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

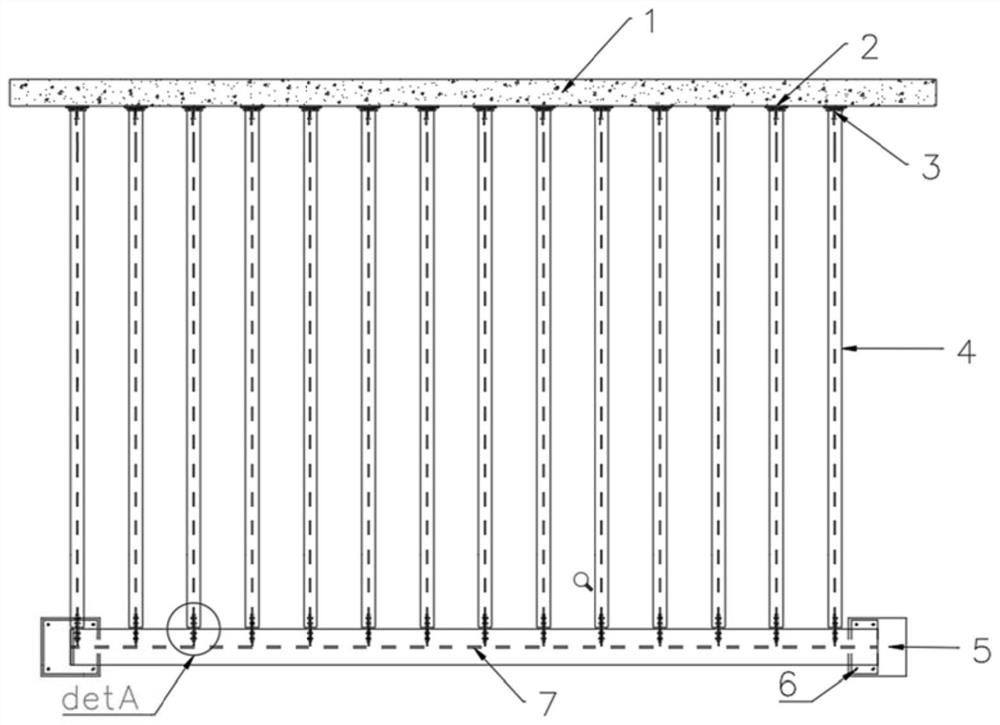

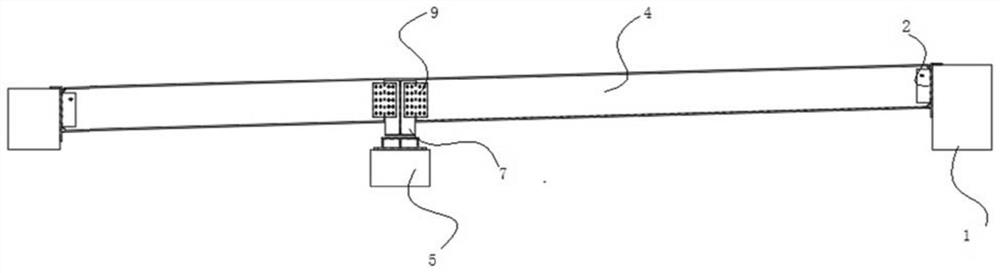

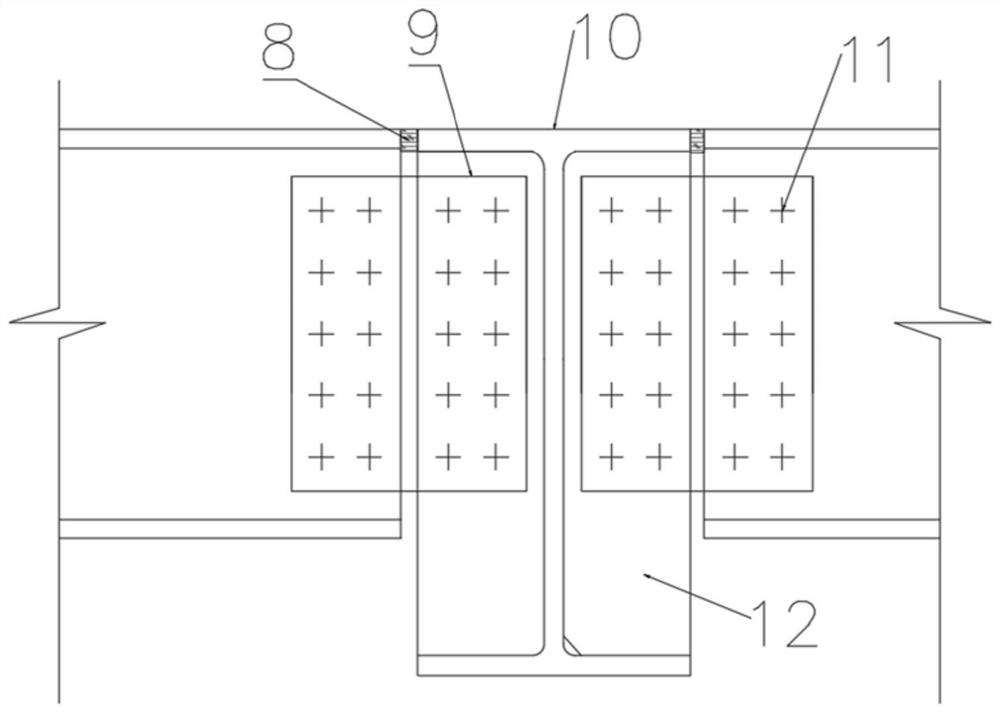

[0022] For the convenient conversion device provided by this scheme, the steel structure storage yard and the assembly yard are overhead, see Figure 1-Figure 2 , which includes a number of conversion columns 5, a main beam 7, a number of secondary beams 4 and a number of connecting plate assemblies.

[0023] The main beam 7 rests on the conversion column 5, and several secondary beams 4 are evenly arranged in a row; one end of the secondary beam 4 is fixedly connected with the concrete wall 1, and the other end is connected with the main beam 7 through the connecting plate assembly, so as to realize the overhead steel structure. The effect of the beams achieves the purpose of efficiently transferring the roof load to the concrete steel structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com