A Charge Structure Suitable for Low Temperature Ignition

A low-temperature ignition and charge technology, which is applied to rocket engine devices, gas turbine devices, jet propulsion devices, etc., can solve the problems of low detonation heat value, slow reaction rate, and delayed ignition of propellants, so as to improve ignition reliability and operation Convenience, improve the effect of delayed ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

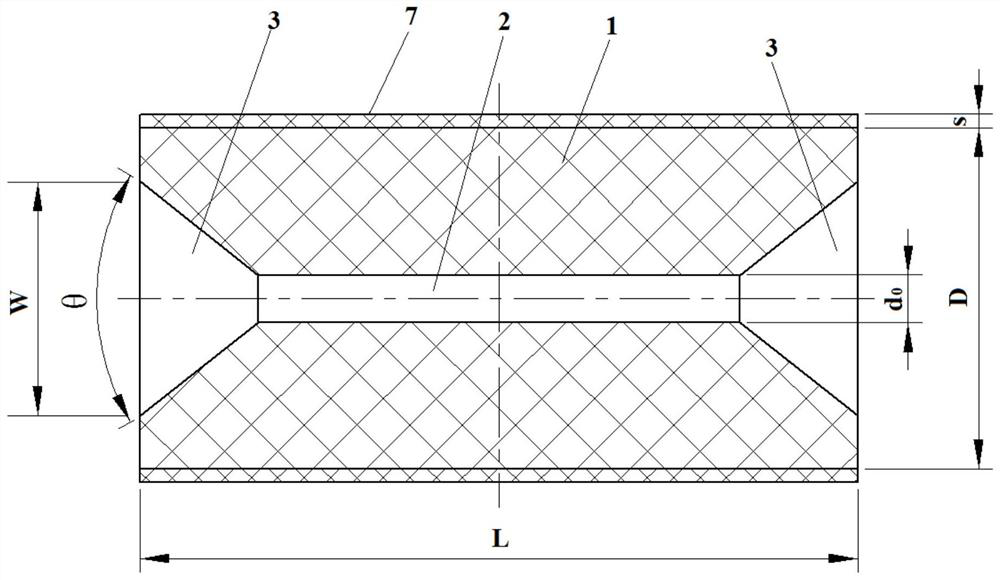

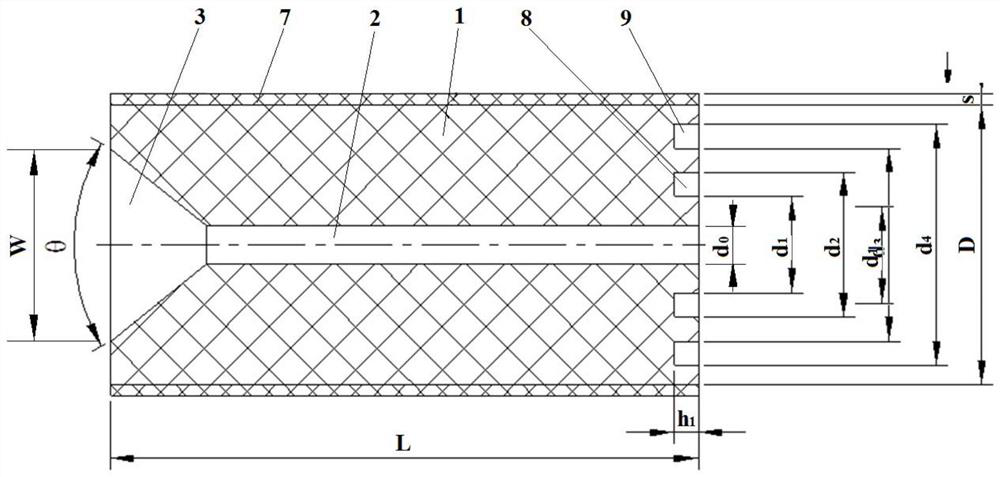

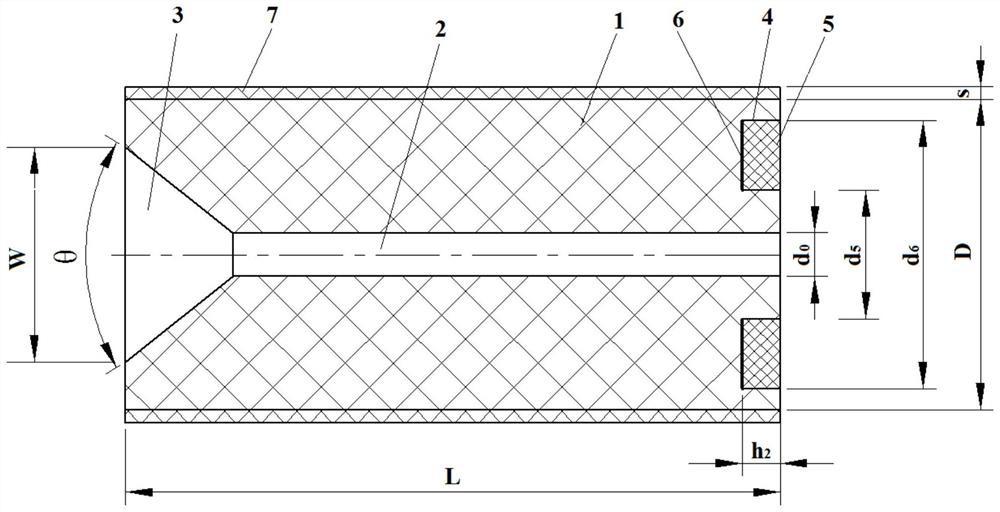

[0049] This embodiment provides a charge structure suitable for low temperature ignition, such as image 3 As shown, it includes a propellant grain 1, and the center of the propellant grain 1 is provided with a central hole 2 through both ends along the axial direction;

[0050] One end of the propellant grain 1 is provided with an inner tapered opening 3 coaxially arranged and connected to the central hole 2;

[0051] The end surface of the other end of the propellant grain 1 is provided with a igniter ring installation groove 4, and a igniter ring 5 is embedded in the igniter ring installation groove 4, and the igniter ring 5 is coaxial with the central hole 2 set up;

[0052] One end face of the igniting drug ring 5 and the groove bottom of the igniting drug ring mounting groove 4 are bonded by a nitrocellulose solution adhesive layer 6;

[0053] A cladding layer 7 is arranged on the side wall of the propellant grain 1 .

[0054] As a preferred solution of this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com