Humidifying micro-mixing burner

A burner, micro-mixing technology, applied in burners, gas fuel burners, combustion chambers, etc., can solve problems such as inability to meet pollutant emission requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

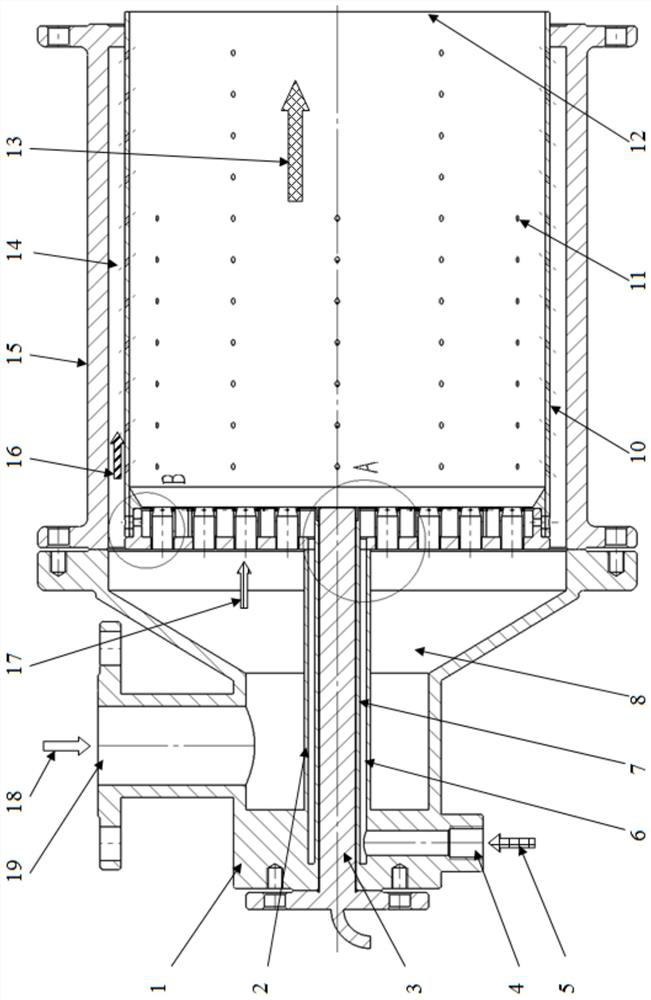

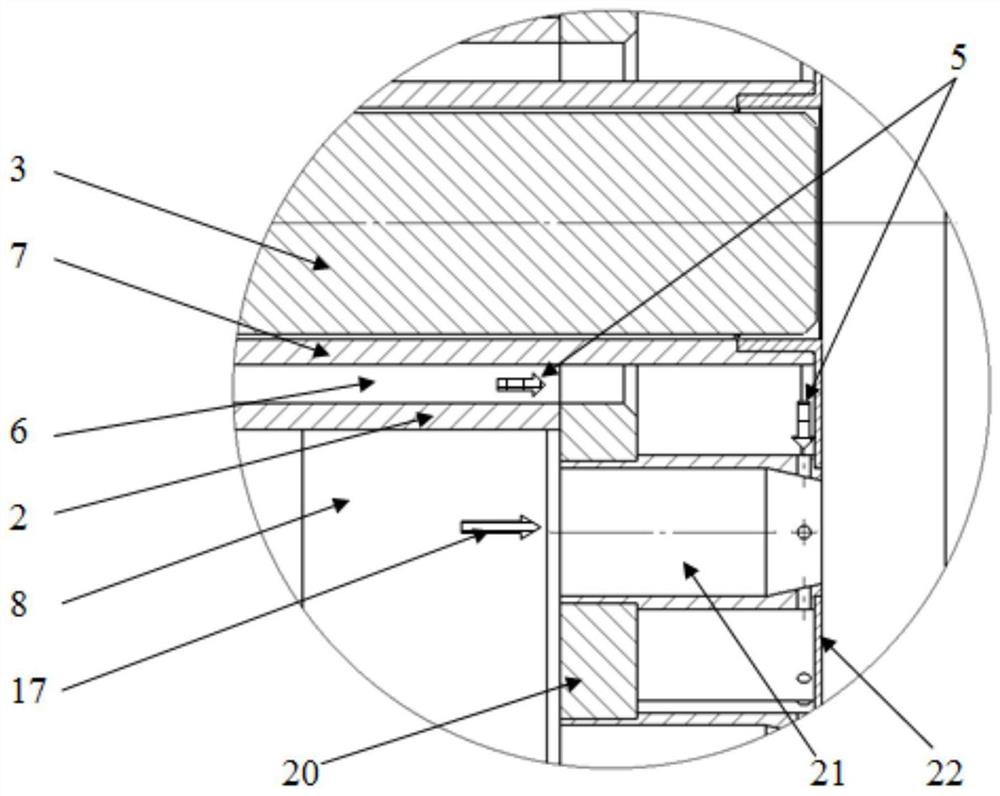

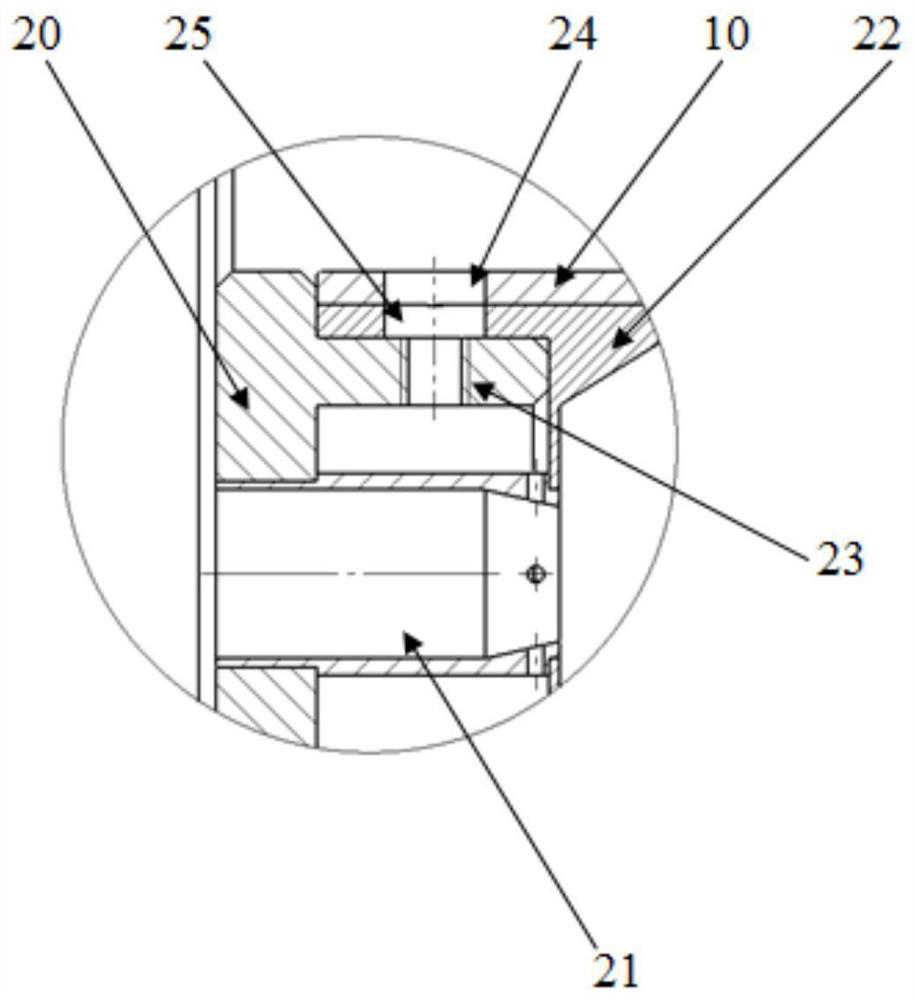

[0035] Such as Figure 1-Figure 9 As shown, a humidification micro-mixed burner, the average temperature of the burner outlet 12 is 1500°C, the average temperature of the inlet of the humidified air 18 is 300°C, the water vapor volume dilution rate is 0.15, including the burner top cover 1, several micro Mixing nozzle 21, air distribution cavity 8, fuel distribution cavity 6, positioning front end cover 20, positioning rear end cover 22, flame tube 10, casing 15 and electric igniter 3, at the center of the burner top cover 1 A through hole is opened, and the electric igniter 3 is installed in the through hole, and a fuel distribution cavity 6 and an air distribution cavity 8 arranged co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com