Heating equipment for chemical production

A technology of heating equipment and chemical production, applied in the chemical industry, can solve the problems of increased thickness of slag agglomeration, excessive bonding, affecting heating air permeability and dredging volume, etc., to achieve continuous feeding improvement and cleaning operation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

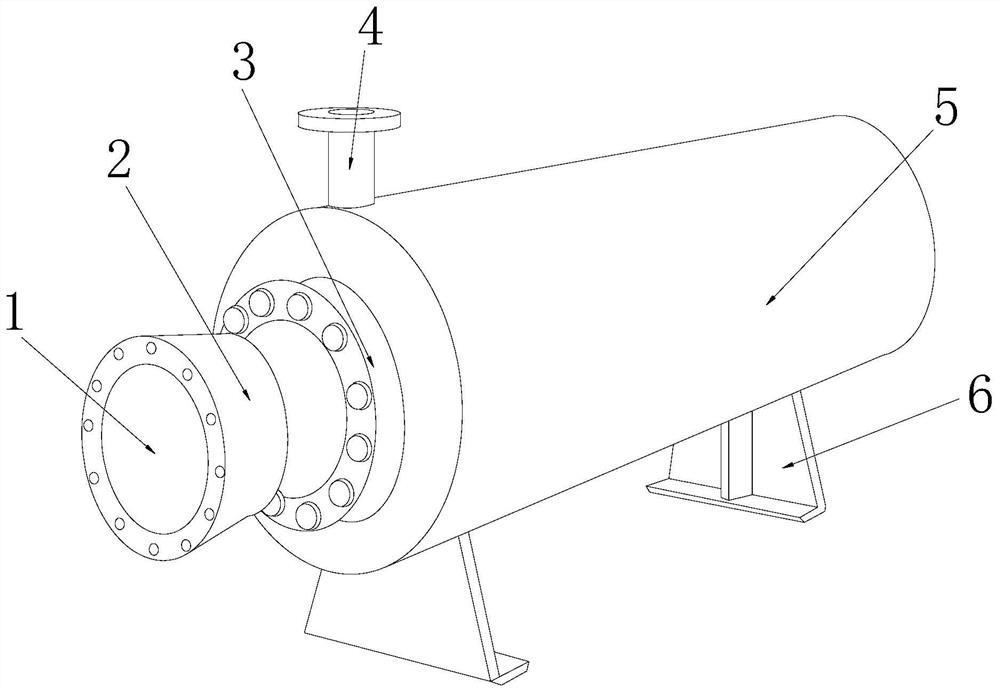

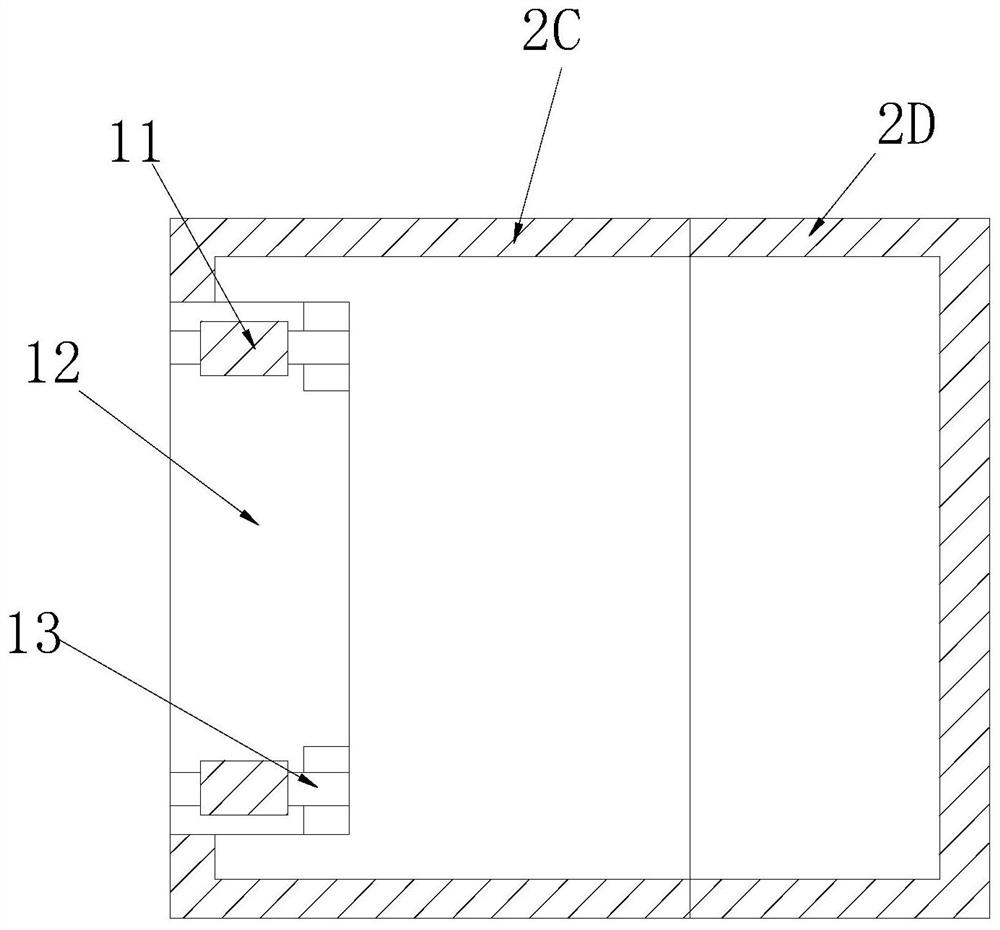

[0035] see Figure 1-Figure 8 , the present invention provides a kind of heating equipment for chemical production, its structure comprises: locking rod plunger block 1, capillary guide cap groove 2, flange plate ring 3, extracting liquid pipe 4, heating roller 5, The support frame plate 6, the thin tube guide cap groove 2 is nested in the front side of the flange ring 3 and communicates with each other, the thin tube guide cap groove 2 is fastened together with the locking rod plunger block 1 and The axes are collinear, and the liquid extraction pipe 4 is inserted on the top of the front side of the heating roller 5 and is perpendicular to each other. 5 is nested on the rear side of the flange ring 3 and communicates with each other. The thin tube guide cap groove 2 is provided with a slide clip thin tube holder 2A, a hydraulic propeller disc 2B, a long sleeve groove 2C, and a short buckle groove 2D, the sliding clip thin tube rack 2A is mechanically connected with the hydra...

Embodiment 2

[0043] see Figure 1-Figure 8 , the present invention provides a kind of heating equipment that is used for chemical industry production, and other respects are identical with embodiment 1, and difference is:

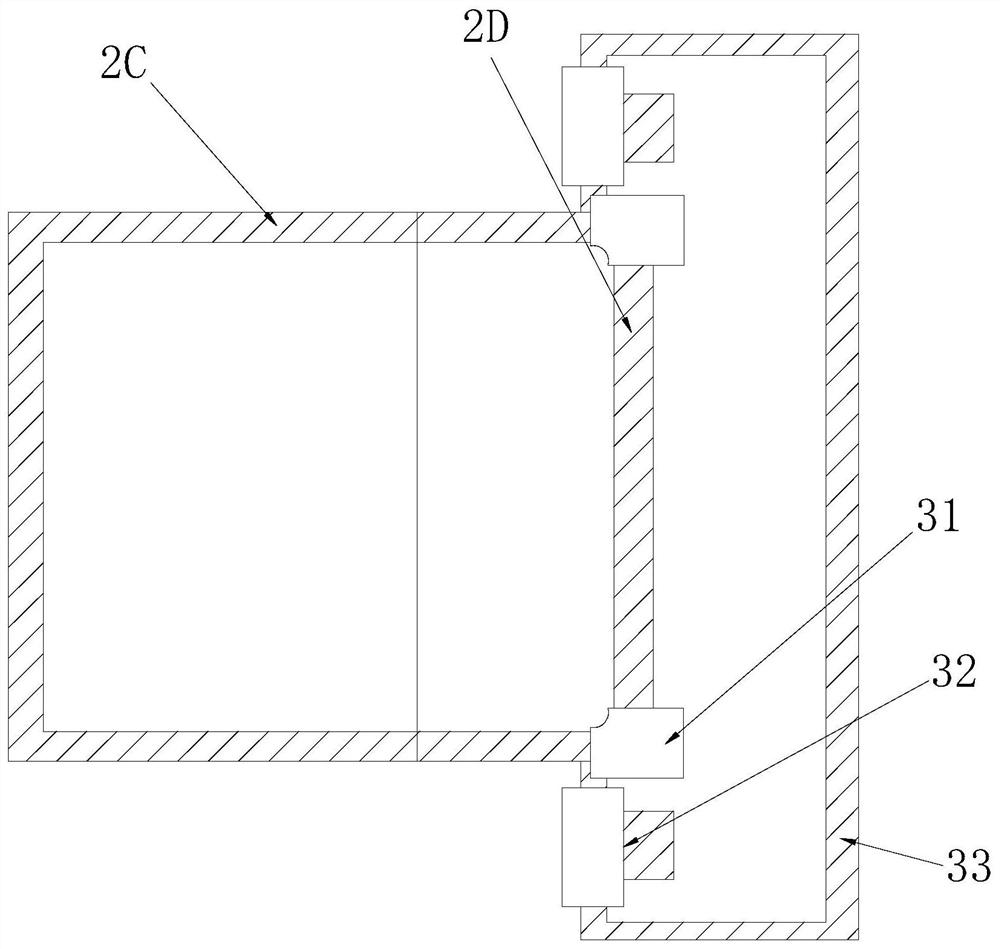

[0044] see image 3 , the flange ring 3 is composed of an angled edge-wrapping plate 31, a screw cap 32, and a flange ring groove 33. The angled edge-wrapping plate 31 is inserted in the left side of the flange ring groove 33, and the screw cap 32 It is threadedly connected with the flange ring groove 33 and is perpendicular to each other. The end angle operation effect of the inner wrapping sleeve is realized in the flange ring groove 33 through the angled edge wrapping plate 31, and the overall locking stability of the structure is improved.

[0045] see Figure 6 , the folded corner edge plate 31 is composed of a concave button plate 311, a ball cap trapezoidal seat 312, and an edge wrapping liner 313. The concave button plate 311 and the ball cap trapezoidal seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com