Material for forming organic film, patterning process, and polymer

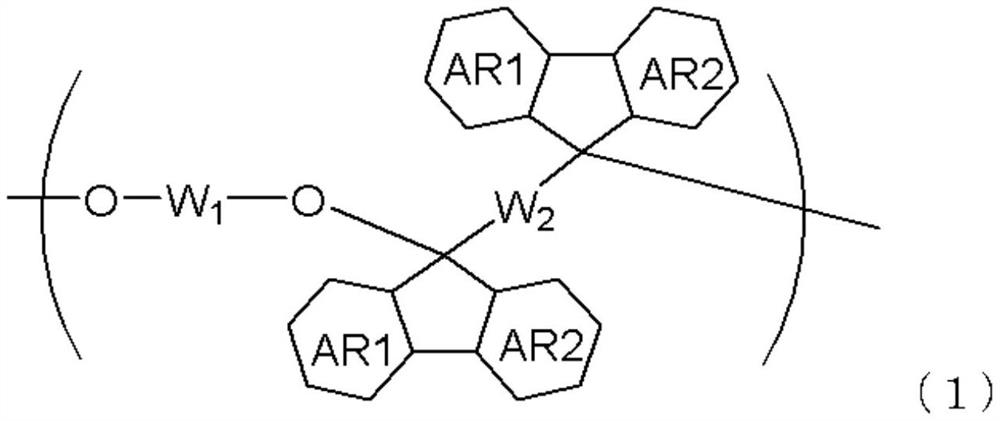

An organic film and polymer technology, applied in the field of coating-type organic films, can solve the problems of difficulty in meeting, high crystallinity of crosslinking agents, low solubility in organic solvents, etc., and achieves excellent twist resistance, excellent etching resistance, and excellent etching resistance. The effect of patience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0184] Hereinafter, synthesis examples, examples, and comparative examples are given to further describe the present invention in detail, but the present invention is not limited thereto. In addition, in terms of molecular weight and degree of dispersion, polystyrene-equivalent weight average molecular weight (Mw) and number average molecular weight (Mn) obtained by gel permeation chromatography (GPC) using tetrahydrofuran as an eluent were obtained, And the degree of dispersion (Mw / Mn) was calculated.

Synthetic example

[0185] Synthesis Example Synthesis of Polymers for Organic Membrane Materials

[0186] When synthesizing the polymers (A1) to (A8) for organic membrane materials, the following compound group B: (B1) to (B5) and compound group C: (C1) to (C4) are used.

[0187] Compound group B:

[0188] [chemical 19]

[0189]

[0190] Compound group C:

[0191] [chemical 20]

[0192]

Synthetic example 1

[0193] [Synthesis Example 1] Synthesis of Polymer (A1)

[0194] 50.0 g of compound (B1), 31.6 g of compound (C1), and 300 g of 1,2-dichloroethane were made into a suspension at an internal temperature of 60° C. under a nitrogen atmosphere. 8 ml of methanesulfonic acid was slowly added, and after confirming that the exotherm ceased, the reaction was carried out at an internal temperature of 60° C. for 6 hours. After cooling to room temperature, 500 ml of methyl isobutyl ketone was added, the organic layer was washed six times with 100 g of pure water, and then the organic layer was dried under reduced pressure. After adding 150 g of tetrahydrofuran (THF) to the residue to obtain a uniform solution, the polymer was reprecipitated with 1000 g of hexane. The precipitated polymer was separated by filtration, washed twice with 300 g of hexane, and recovered. The recovered polymer was vacuum-dried at 50°C, whereby a polymer (A1) was obtained. The weight average molecular weight (M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com