Object transfer cam control system

A cam control and object technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problems of poor control accuracy, stability, timeliness and adaptability, disordered paper sorting, and interleaving, etc. Achieve good prediction accuracy and adaptive ability, improve generalization ability, improve accuracy and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

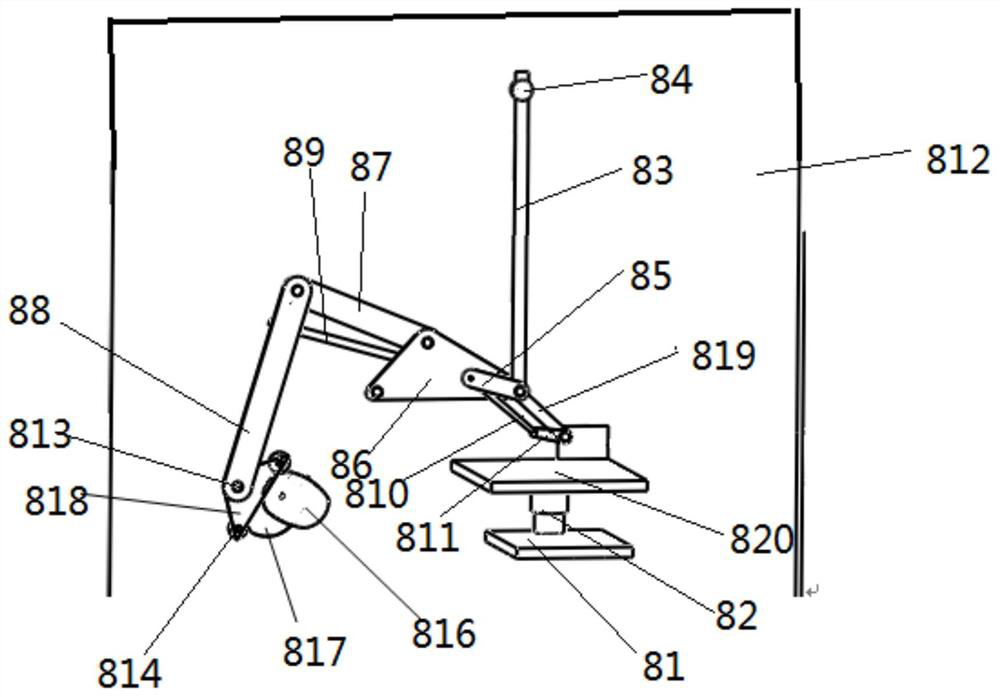

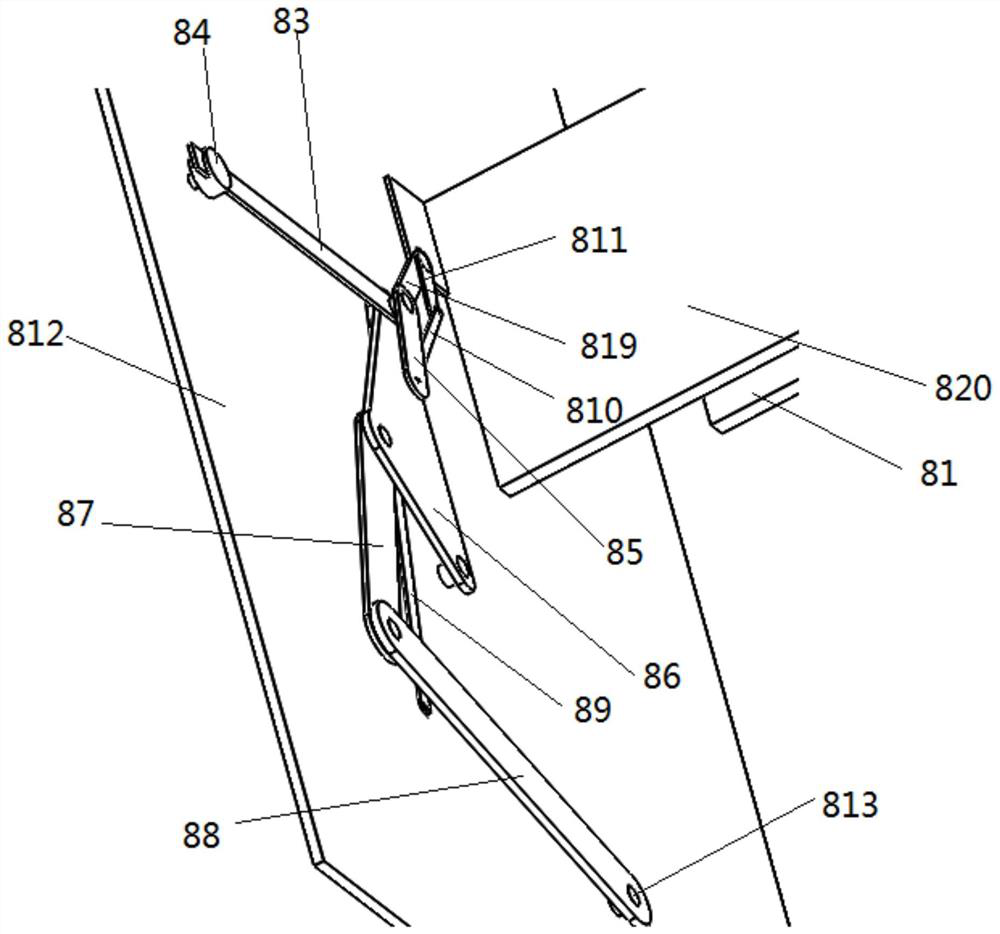

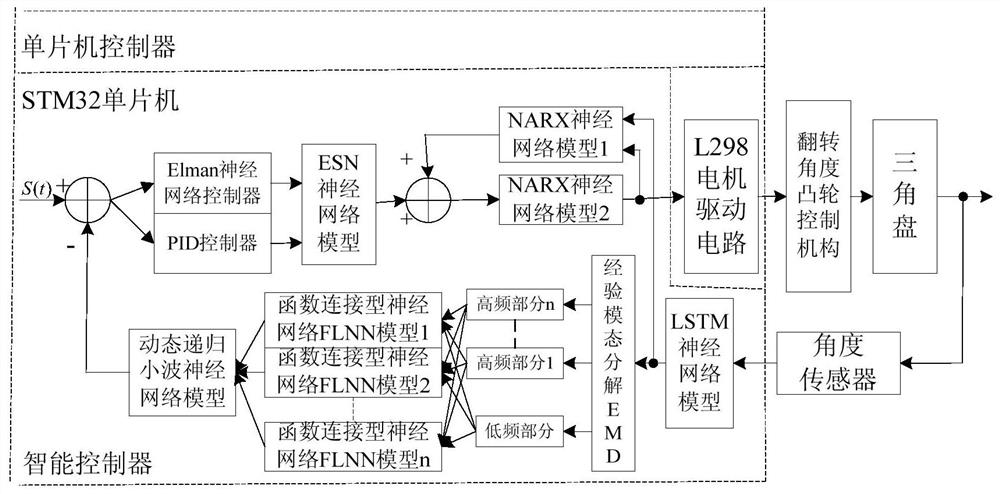

[0027] This embodiment provides a paper delivery system, such as figure 1 and 2 As shown, it includes a single-chip controller, a side plate 812, a flip angle cam control mechanism, a connecting rod drive mechanism and a suction cup mechanism. The flip angle cam control mechanism includes a flip motor, and a pressing cam 817 coaxially connected to the output shaft of the flip motor. and positioning cam 816. The single-chip controller drives the pressure cam 817 and the positioning cam 816 to rotate synchronously through 30 ° of reciprocating rotation by controlling the overturning motor, and drives the triangular plate 818 in the connecting rod drive mechanism to rotate 30 ° reciprocatingly with an angle sensor (the preferred model is TQ513), and then The suction cup 81 in the suction cup mechanism is driven to rotate back and forth through 90 °.

[0028] The connecting rod driving mechanism includes a triangular disc 818, a rotating main rod 88, a pulling mechanism and an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com