Temperature control module in biological reaction instrument

A biological reaction and instrument technology, applied in the direction of instruments, temperature control, non-electric variable control, etc., can solve the problems of no self-regulation of heat transfer uniformity, reduced heat conduction effect, low thermal conductivity, etc., to shorten biochemical reaction time, Effects of faster heating and cooling rate and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

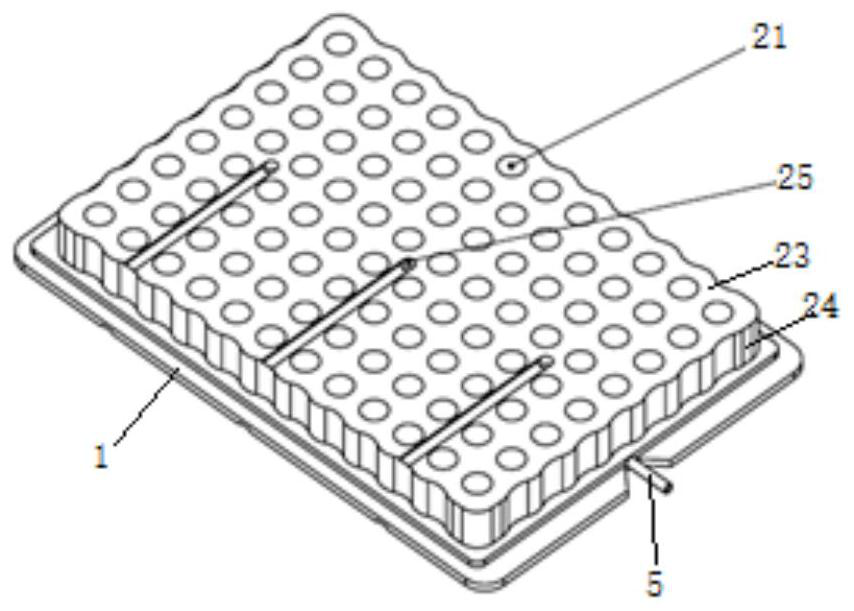

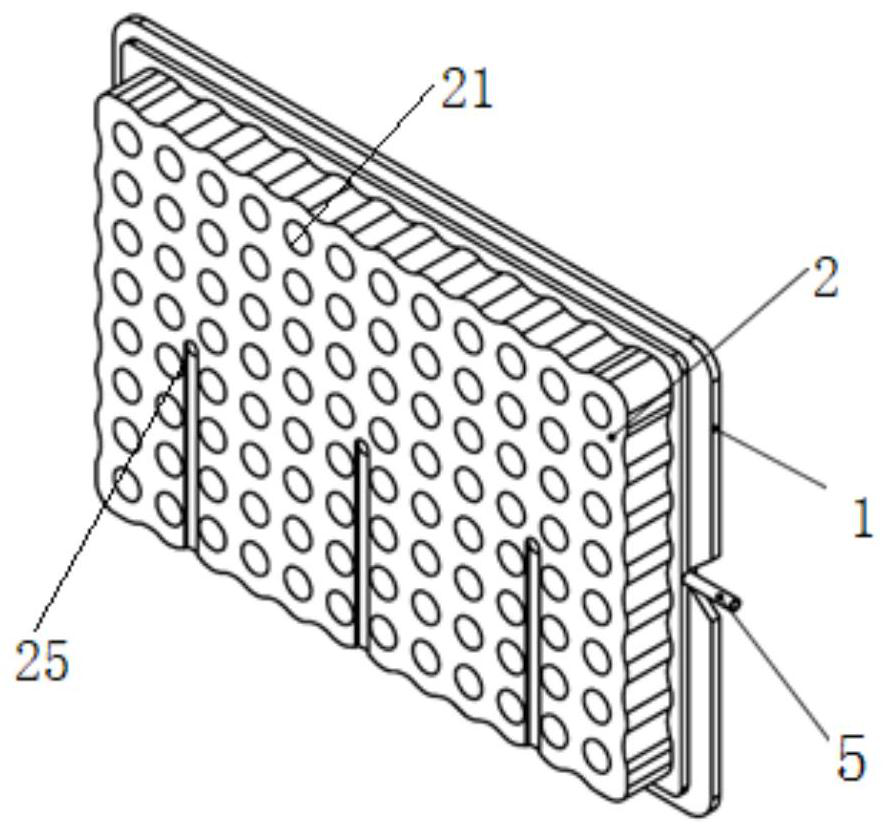

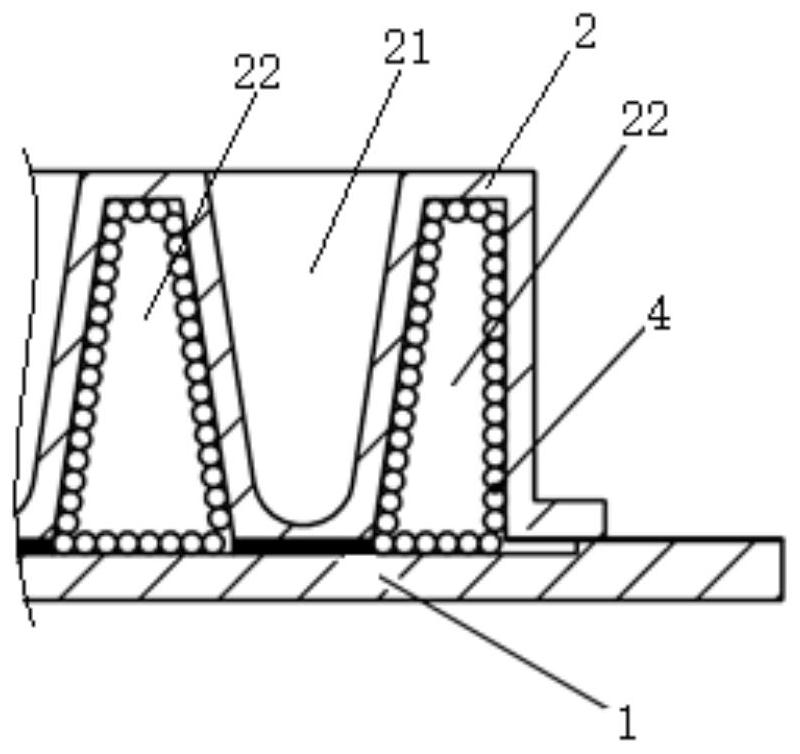

[0025] see in conjunction Figure 1 to Figure 5 As shown, according to an embodiment of the present invention, a temperature control module in a bioreactor is provided, including a flat plate 1 and an upper cover 2, the upper cover 2 is arranged opposite to the flat plate 1 and connected as a whole, the upper The cover 2 is configured with a plurality of container holes 21 for placing reaction consumables. On the side of the upper cover 2 facing the flat plate 1, an accommodating cavity 22 is formed between any two adjacent container holes 21, and each The accommodating cavities 22 communicate with each other, and the accommodating cavities 22 are filled with a phase change heat transfer medium 3 . In this technical solution, the accommodating chamber 22 is filled with the phase change heat transfer medium 3, and when the temperature control module in the bioreactor is partially heated by the heat source, the area near the heat source in the accommodating chamber 22 The liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com