Transfer process and transfer equipment for LED lamp beads

A technology of LED lamp bead and process, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of inability to meet the diversified needs of products, low transfer accuracy, and low transfer efficiency of SMT process, so as to reduce production difficulty , High transfer accuracy and high transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

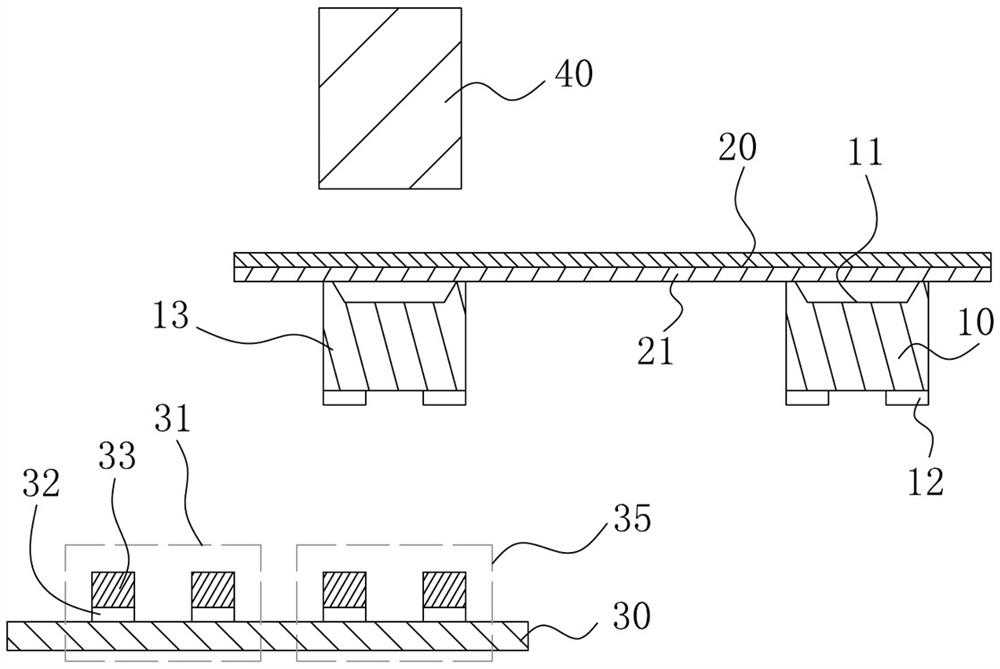

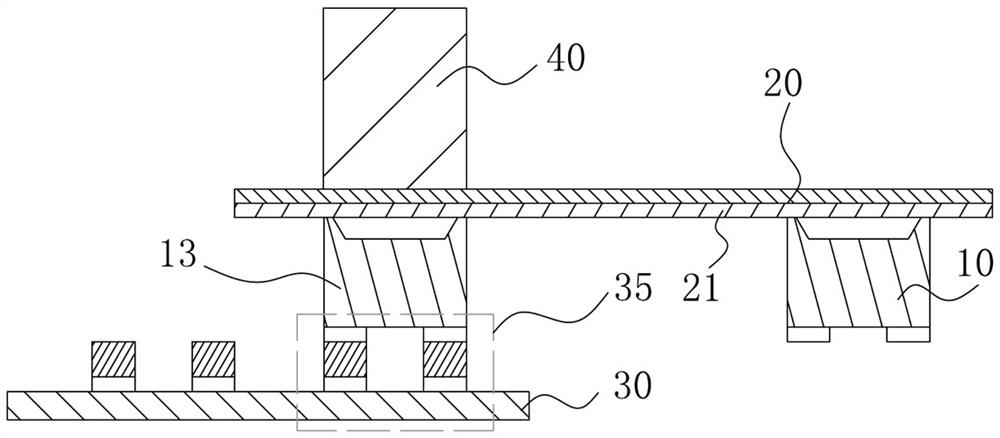

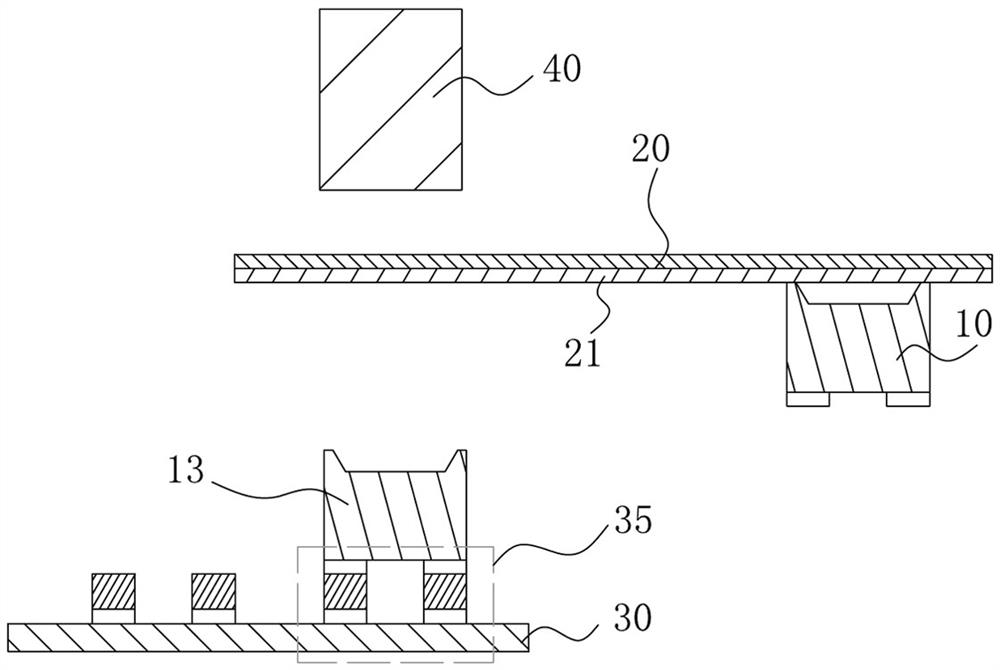

[0039] Such as Figure 1~3 As shown, the first embodiment provided by the present invention, the transfer process of LED lamp beads, includes the following steps:

[0040] a) Provide LED lamp beads 10 and a carrier film 20, a plurality of LED lamp beads 10 are arranged on the bottom surface of the carrier film 20; the bottom layer of the carrier film 20 is the adhesive layer 21; the top surface of the LED lamp beads 10 is the light-emitting surface 11 , pins 12 are provided on the bottom surface; the light-emitting surface 11 is pasted on the adhesive layer 21 .

[0041] b) Provide a driving backplane 30, the top surface of the driving backplane 30 is provided with a plurality of mounting areas 31; the mounting area 31 is provided with pads 32, and solder paste 33 is provided on the pads 32.

[0042] c) if figure 1 As shown, at least one LED lamp bead 10 is selected as the target LED lamp bead 13, and at least one patch area 31 is selected as the target patch area 35; any on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com