Method for rapidly activating proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve the problems of occupying production resources, troubles in the practical application of fuel cells, and time-consuming use, and achieve simple and convenient operation and activation effect significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

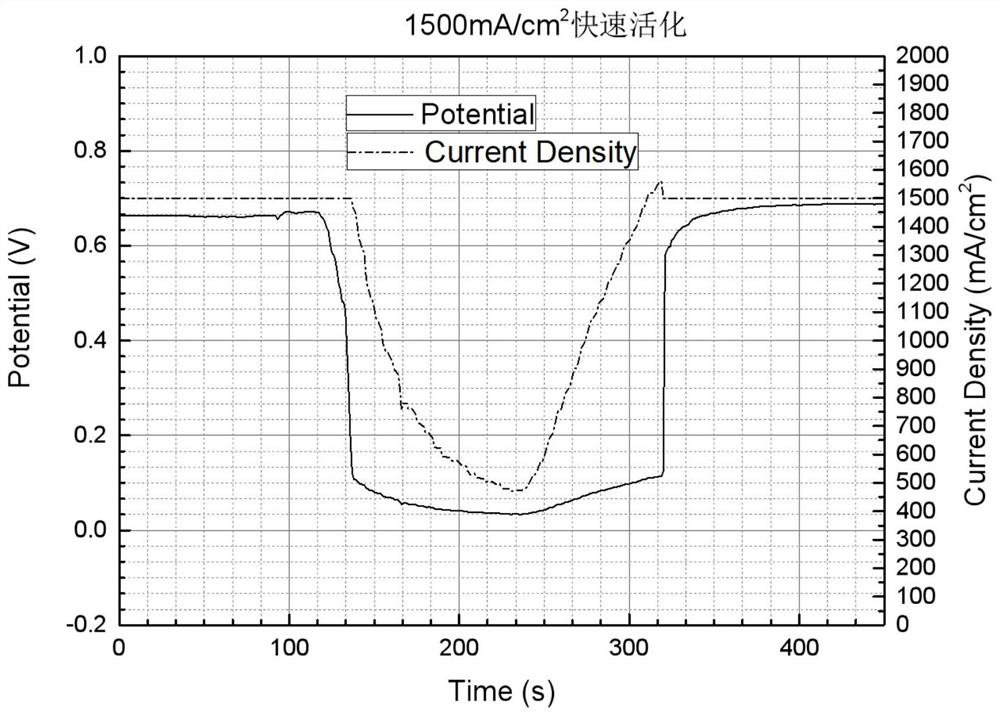

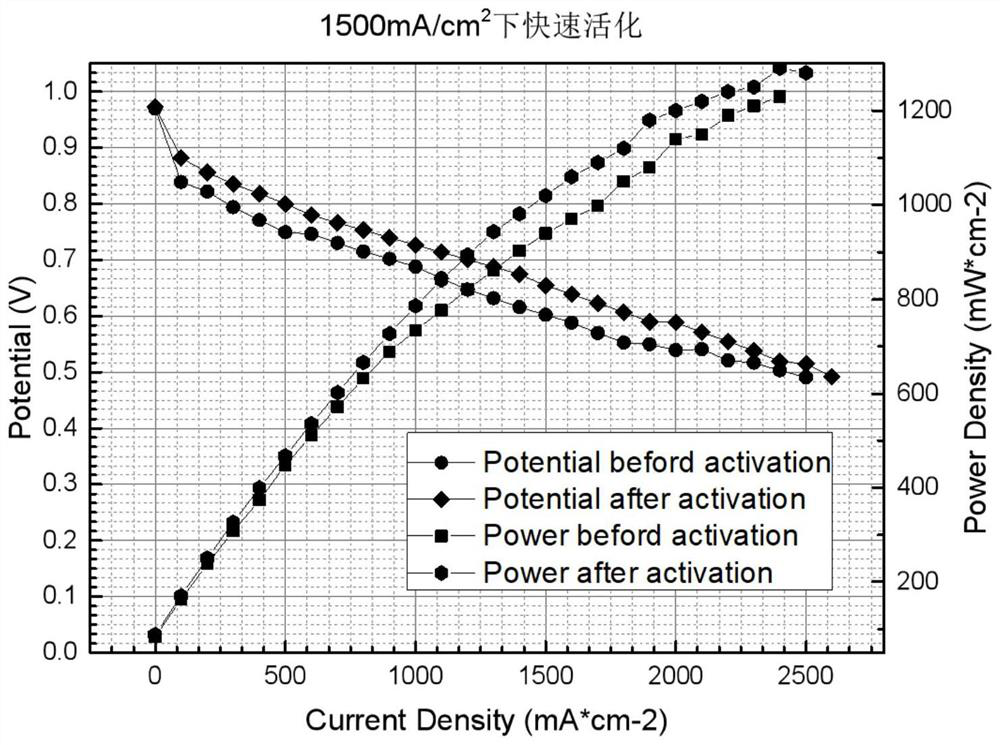

[0024] Check the assembled proton exchange membrane fuel cell for leaks to see if there is any air leakage in the connecting part, and if there is any air leakage, it needs to be solved; The battery is subjected to a constant temperature of 75°C, and the battery is purged with nitrogen before the battery is filled with hydrogen to remove impurity gases in the flow channel. After purging for a certain period of time, switch to the hydrogen-air mode to supply the normal power generation of the fuel cell, in which the anode back pressure is 150kPa, the anode humidity is 50%, the cathode back pressure is 130kPa, the cathode humidity is 70%, and the anode / cathode excess coefficient is 2.0 / 2.0 to ensure the fuel gas Sufficient supply, and at 100mA / cm 2 Apply current to the interval until the current density reaches 1500mA / cm 2 , remain stable for a while at this current density.

[0025] When the battery is running stably at this current density, the air supply on the cathode side...

Embodiment 2

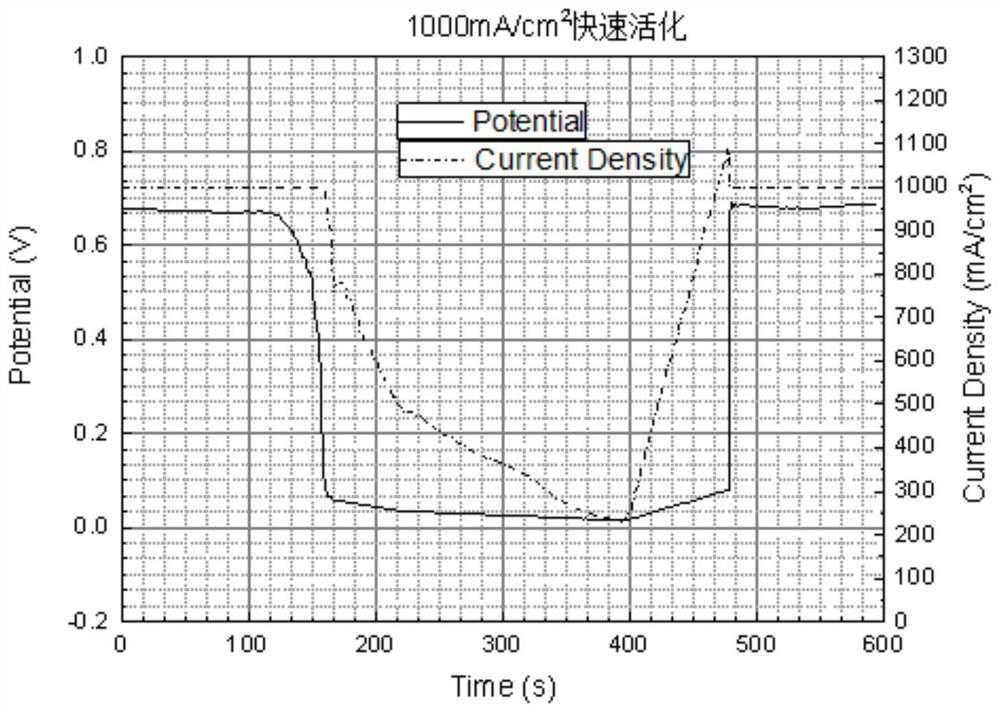

[0029] Check the assembled proton exchange membrane fuel cell for leaks to see if there is any air leakage in the connecting part, and if there is any air leakage, it needs to be solved; The battery is subjected to a constant temperature of 75°C, and the battery is purged with nitrogen before the battery is filled with hydrogen to remove impurity gases in the flow channel. After purging for a certain period of time, switch to the hydrogen-air mode to supply the normal power generation of the fuel cell. The anode back pressure is 150kPa, the anode humidity is 50%, the cathode back pressure is 150kPa, the cathode humidity is 70%, and the anode / cathode excess coefficient is 2.0 / 2.0 to ensure fuel gas Sufficient supply, and at 100mA / cm 2 Apply current to the interval until the current density reaches 1000mA / cm 2 , remain stable for a while at this current density.

[0030] When the battery is running stably at this current density, the air supply on the cathode side is switched ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap