Method for exhaust gas aftertreatment, and exhaust gas aftertreatment system

A technology of exhaust gas post-treatment and exhaust gas pipeline, which is applied in the direction of electronic control of exhaust treatment devices, exhaust treatment, exhaust devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

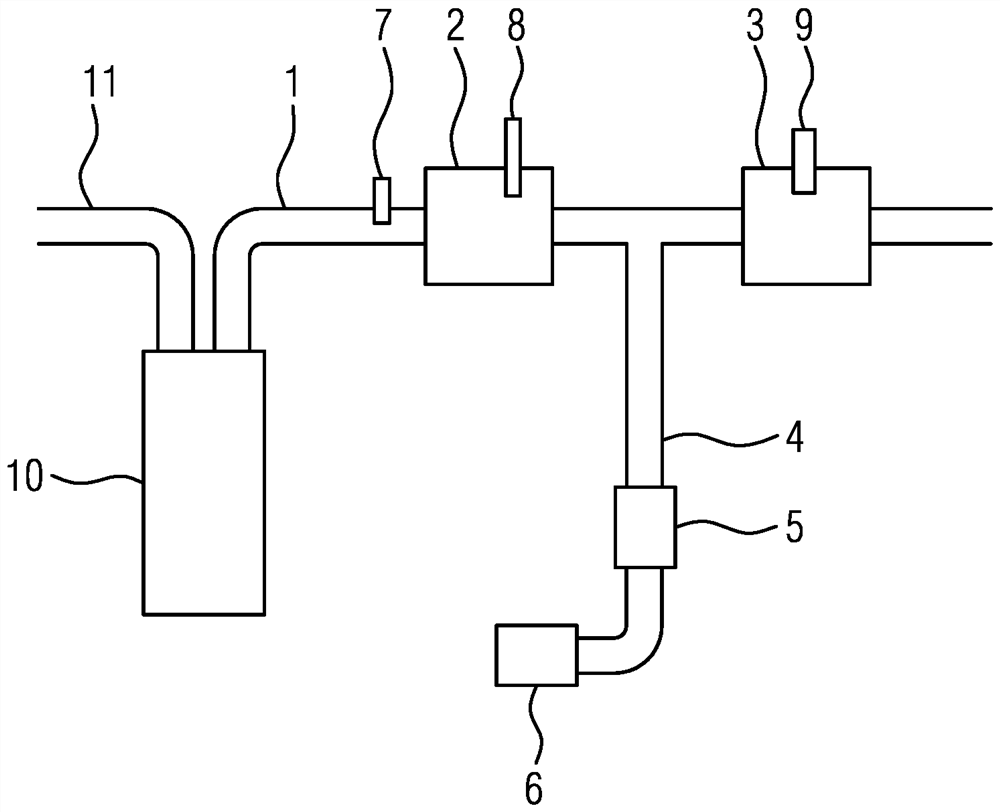

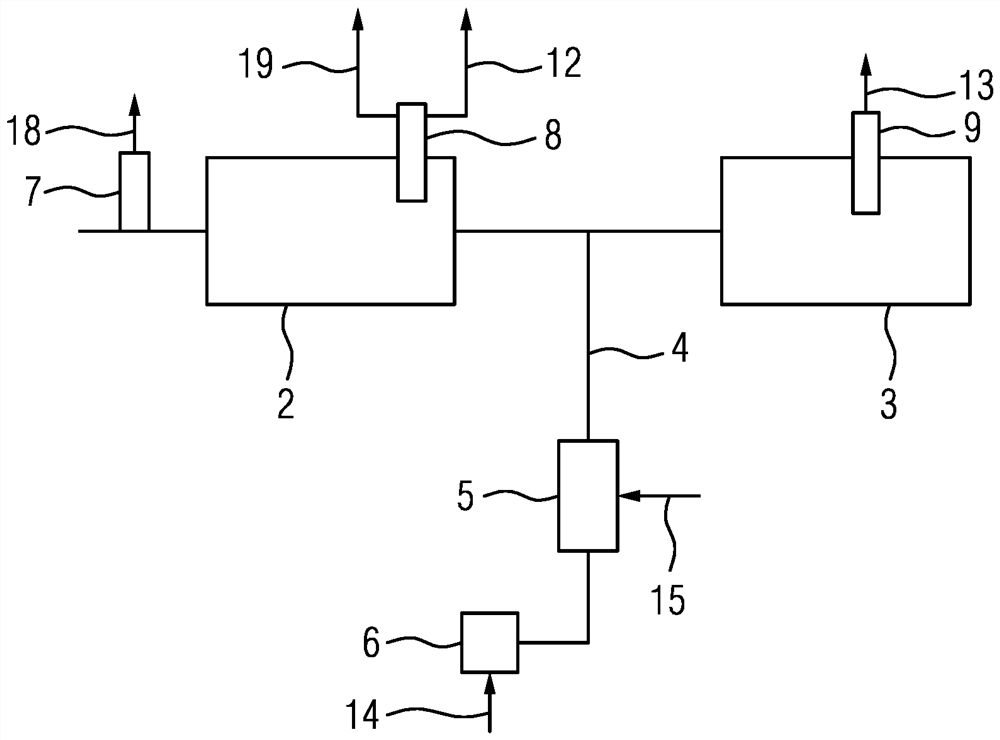

[0047] figure 1 A gasoline engine (spark ignition engine) 10 is schematically shown with an air supply line 11 and an exhaust gas line 1 . Arranged in the exhaust gas line 1 is a first three-way catalytic converter 2 followed by a second three-way catalytic converter 3 . A linear lambda probe 7 is arranged upstream of the first three-way catalytic converter 2 . The first three-way catalytic converter 2 is provided with a NOx sensor 8 arranged in the catalytic converter at 2 / 3 of the length of the catalytic converter.

[0048] The second three-way catalytic converter 3 is located downstream of the first three-way catalytic converter 2 and has a binary lambda probe 9 . Leading into the exhaust gas duct 1 between the two catalytic converters 2 , 3 is a secondary air line 4 , through which secondary air is blown in by means of a secondary air pump 6 and a secondary air valve 5 .

[0049] refer to figure 2 The operation mode of the exhaust gas aftertreatment system described a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com