Remained germ rice processing machine for positioning single rice grain and grinding middle section and remained germ rice with complete germs

A technology of middle-section and embryo-retaining rice is applied to the field of embryo-retaining rice processing machines and embryo-retaining rice with complete embryos. and other problems, to achieve the effect of easy promotion, reduced volume, and small processing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

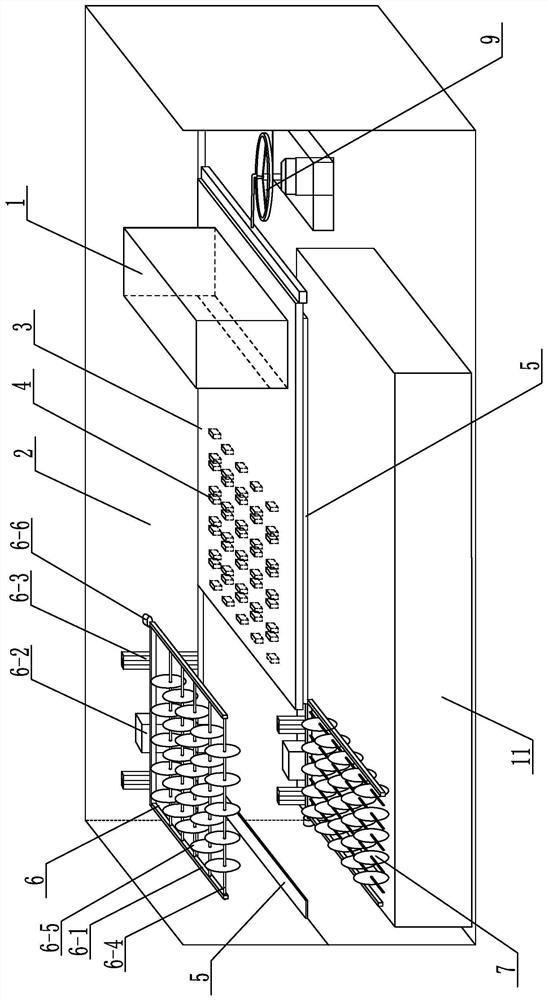

[0023] Specific implementation mode one: combine Figure 1 to Figure 7 This embodiment is described. In the present invention, for the convenience of description and understanding, the figure 1 The left side of the figure in the figure is the left half of the rice processing machine, with figure 1 The right side of the figure in the middle is the right half of the rice processing machine, and the left or right description here is not limited to the technical characteristics of the actual rice processing machine.

[0024]The germ rice processing machine in the middle section of the single-grain rice positioning mill in this embodiment includes a rice falling device 1, a frame 2 and a rice loading plate 3, the rice loading plate 3 is horizontally slid and installed in the frame 2, and the rice falling device 1 is installed in the frame 2 Inside and on the upper end face of the rice loading plate 3, a plurality of rice falling grooves 4 are provided in the form of an array on th...

specific Embodiment approach 2

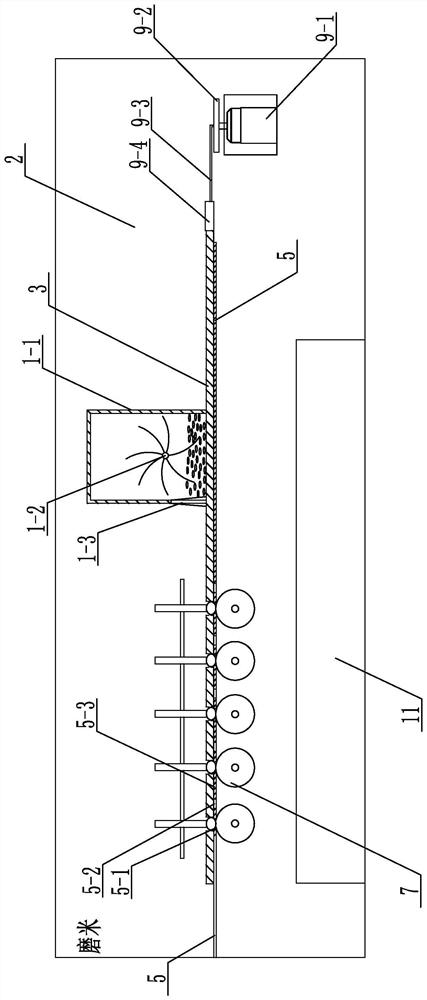

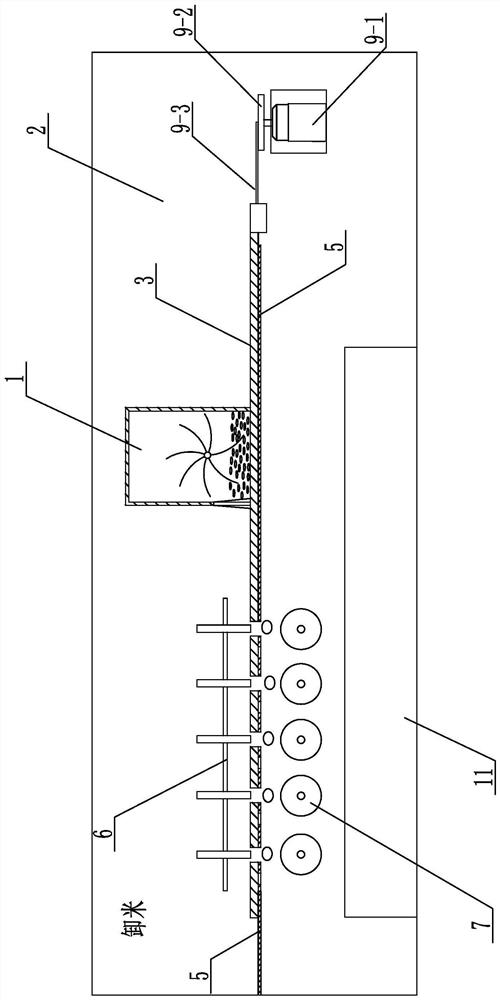

[0026] Specific implementation mode two: combination Figure 1 to Figure 4 Describe this embodiment, the rice falling device 1 of this embodiment comprises the rice falling bin 1-1, the rice falling dial 1-2 and the rice falling brush 1-3, the rice falling dial 1-2 is rotatably installed in the rice falling bin 1 In -1, the rice falling brush 1-3 is installed on the bottom of the left and right sides of the rice falling warehouse 1-1, and the rice falling brush 1-3 is in contact with the rice loading plate 3. Such setting is convenient for slowly filling rice into the falling rice warehouse, preventing the rice grains brought by the fast and large amount of rice from accumulating in the lower part of the rice falling warehouse 1-1, which will affect the accurate rice falling of the rice falling board. In addition, the rice falling dial of this embodiment The power of the wheel 1-2 can be controlled by a motor or a manual handle. The rice falling brush 1-3 scrapes the rice grai...

specific Embodiment approach 3

[0027] Specific implementation mode three: combination Figure 1 to Figure 4 Illustrate this embodiment, the falling rice dial 1-2 of this embodiment comprises a rotating shaft and a plurality of shifting leaves, and the rotating shaft is installed in the rice falling bin 1-1 in rotation, and a plurality of shifting leaves are installed on the rotating shaft in the form of an annular array. In this way, the blades are set in an arc shape, which can prevent a large amount of rice grains from accumulating while supporting the rice grains. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com