Deep screening and crushing process of raw coal system

A technology of deep screening and raw coal, applied in grain processing and other directions, can solve the problems of large crushing particle size, poor raw coal lifting capacity, low screening efficiency, etc., and achieve the effect of reducing raw coal volume, processing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

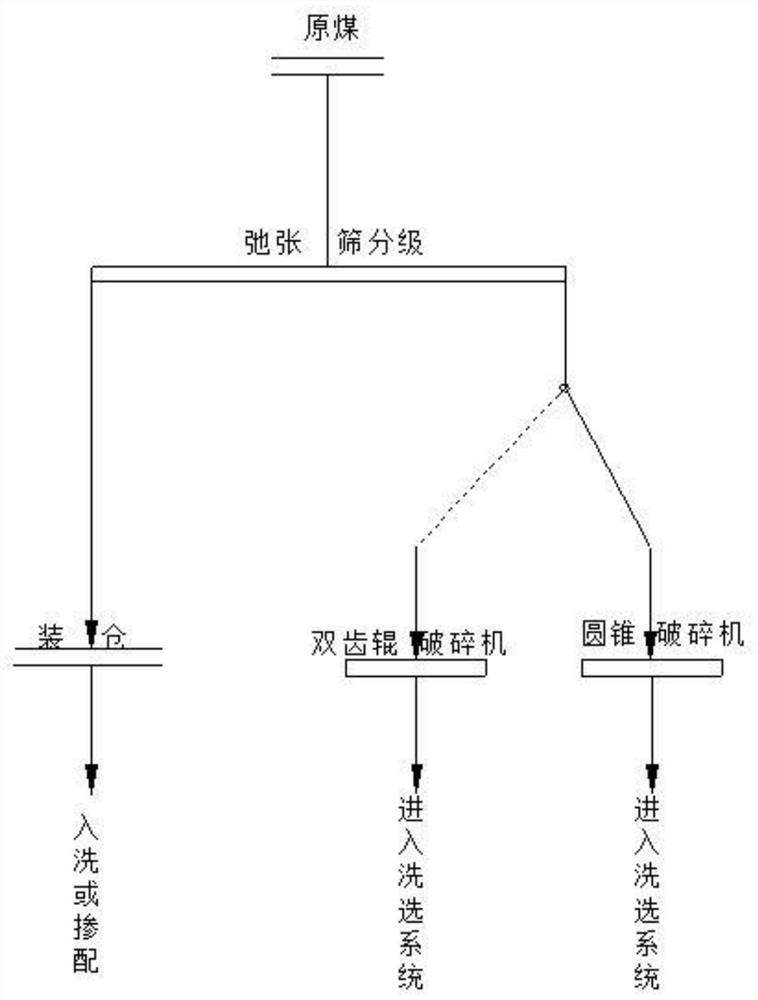

[0022] refer to figure 1 , the present invention specifically adopts the following embodiments: including raw coal, a screening system and a crushing system, the raw coal is connected to the screening system through a lifting device, the screening system is connected to the crushing system through a large-inclination belt conveyor, and the number of large-inclination belt conveyors At least four, the screening system includes a double-layer relaxation screen, the crushing system includes a double-toothed roller crusher and a cone crusher, and the number of the double-toothed roller crusher and the cone crusher is at least two and set side by side. The belt angle of the high-inclination belt conveyor is 82.7°, the width is 1.5m, and the transport capacity is greater than 350t. The aperture diameters of the double-layer sieves of the relaxation sieve are respectively greater than 80mm and 40-80mm.

[0023] Proceed as follows:

[0024] 1) The raw coal mined in the mine is tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com