Combined agent for desulfurization of iron fine powder under alkaline conditions and method for desulfurization of pyrrhotite by using the same

A technology of combining medicaments and alkaline conditions, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of high cost, large consumption, and corrosion of flotation equipment in industrial applications, and reduce the probability of shedding, porosity, etc. rate increase, strengthen the effect of flotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

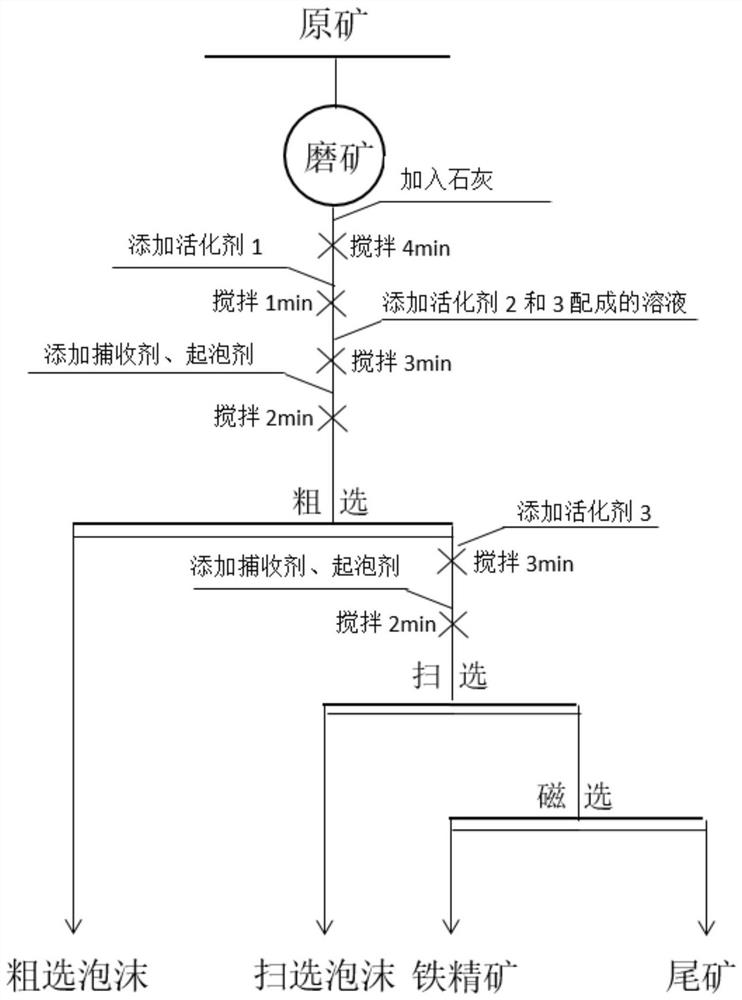

[0033] The iron ore containing pyrrhotite in a certain mine was used for the test. Most of the S element in the ore of this mine is distributed in the pyrrhotite, accounting for 60%. Specific steps are as follows:

[0034] (1) Sizing. The iron ore containing pyrrhotite is subjected to one-stage grinding, the grinding concentration is 69%, and the grinding fineness (-0.074mm) is 54%. The concentration of the obtained pulp was adjusted to 22%, lime was added in an amount of 3kg / t, the pH of the pulp was adjusted to 9, and stirred for 4 minutes;

[0035] (2) Rough selection. In the stirring process, add activator 1, the dosage is 450g / t, and stir for 1min; add the solution prepared by activator 2 and 3 according to the mass ratio of 1:1.2 (reaction time 30min), the dosage is 330g / t, and stir for 3min; Add a combined collector at a dosage of 120g / t, add a foaming agent at a dosage of 8g / t, stir for 2min, and carry out roughing. The roughing time is 12.5min to obtain roughing fo...

Embodiment 2

[0045] The high-sulfur raw ore containing pyrrhotite in a certain mine was selected for the test, and the S element distributed in the pyrrhotite accounted for 45% of the raw ore. The specific implementation steps are as follows:

[0046] (1) Sizing. The magnetite containing pyrrhotite is ground in one stage, the grinding concentration is 65%, and the grinding fineness (-0.074mm) is 52%. The concentration of the obtained pulp was adjusted to 22%, lime was added in an amount of 7kg / t, the pH of the pulp was adjusted to 11, and stirred for 4 minutes;

[0047](2) Rough selection. During the stirring process, add activator 1, the dosage is 660g / t, and stir for 1min; add the solution prepared by activator 2 and 3 according to the mass ratio of 1:1.1 (reaction time 30min), the dosage is 470g / t, and stir for 3min; Add a combined collector in an amount of 130g / t, add a foaming agent in an amount of 9g / t, stir for 2min, and carry out roughing. The roughing time is 13min to obtain rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com