Logistics supply chain management device with automatic sorting function

A logistics supply chain, automatic sorting technology, applied in the field of logistics management, can solve the problem of not having automatic sorting and unloading protection functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

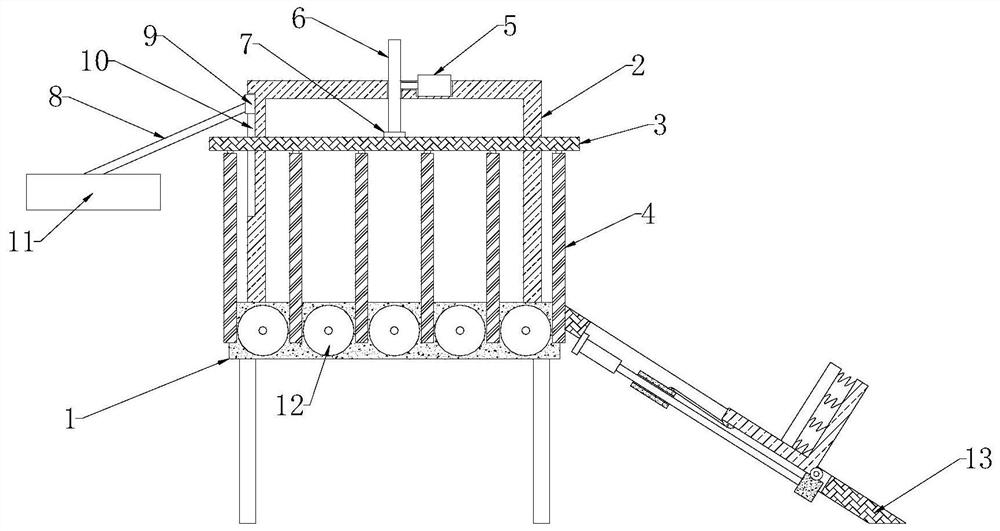

[0027] refer to figure 1 , Figure 4 and Figure 5 , a logistics supply chain management device with an automatic sorting function, comprising a sorting table 1, the sorting table 1 is arranged in a back shape, and the inner wall of the sorting table 1 is equidistantly rotated and installed with transmission rollers 12 with the same structure. A mounting frame 2 is fixedly installed on the top of the picking table 1, and a drive motor 5 is fixedly mounted on the mounting frame 2. The output shaft of the drive motor 5 is fixedly connected with a vertical gear plate 6, and one side of the mounting frame 2 is slidably installed. There is a pole 8, and a scanner 11 is fixedly installed on the side of the pole 8 away from the mounting frame 2, a sorting mechanism is installed inside the mounting frame 2, and a tilting The blanking plate 13 is set, and the blanking protection mechanism is installed on the blanking plate 13, the end of the pole 8 close to the mounting frame 2 is fi...

Embodiment 2

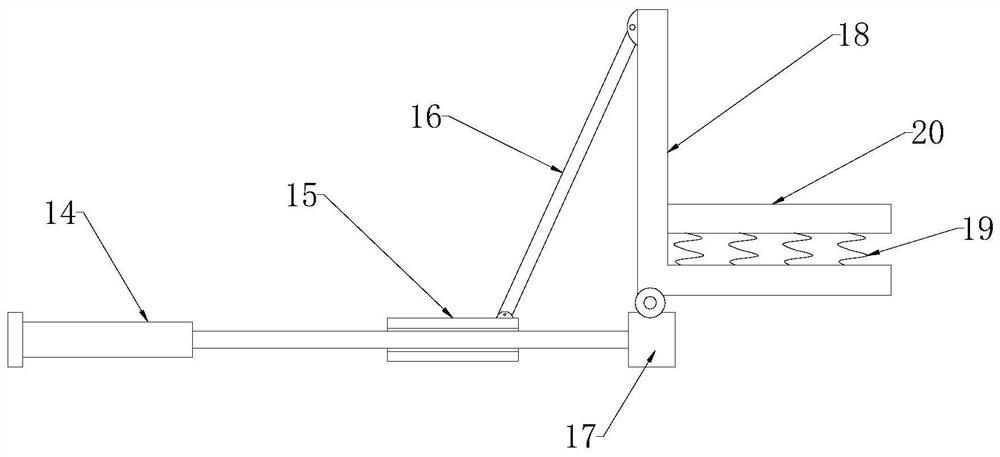

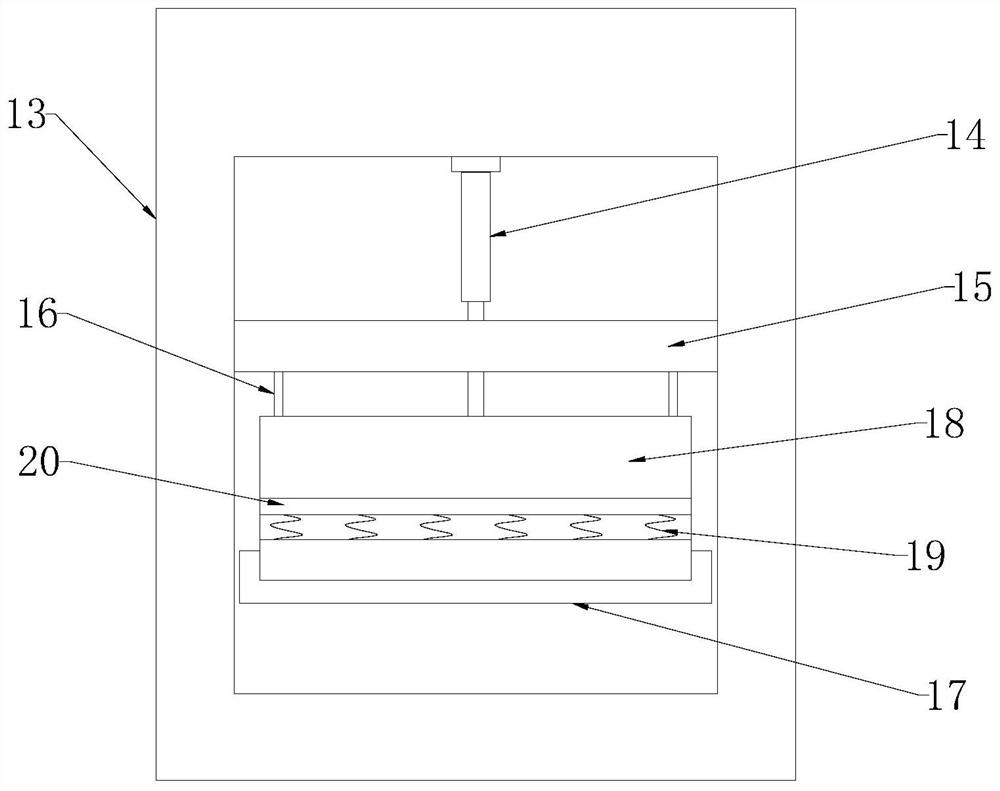

[0031] refer to Figure 1-3 and Figure 5 , the blanking protection mechanism includes an electric telescopic rod 14, a fixed plate 15, a hinged rod 16, a moving plate 17, and a turning plate 18. An installation groove is arranged in the middle of the blanking plate 13, and an electric telescopic rod 14 is fixedly installed in the installation groove. , the fixed plate 15 is fixedly installed in the installation groove, and the movable plate 17 is slidably installed in the installed groove, the fixed plate 15 is located between the movable plate 17 and the sorting table 1, and the top of the movable plate 17 is hinged with a turning plate 18, and the flipping A hinged rod 16 is connected between the plate 18 and the fixed plate 15 .

[0032] Turnover plate 18 is arranged in L-shaped structure, and turnover plate 18 is provided with a buffer assembly, buffer assembly includes buffer spring 19 and buffer plate 20, is slidably installed with buffer plate 20 on the turnover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com