An automatic feeding device for CNC machine tools

A technology of automatic feeding and CNC machine tools, which is applied in the field of CNC machine tools, can solve problems such as low speed and CNC machine tools do not have the function of blanking, and achieve the effect of increasing the feeding speed and working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

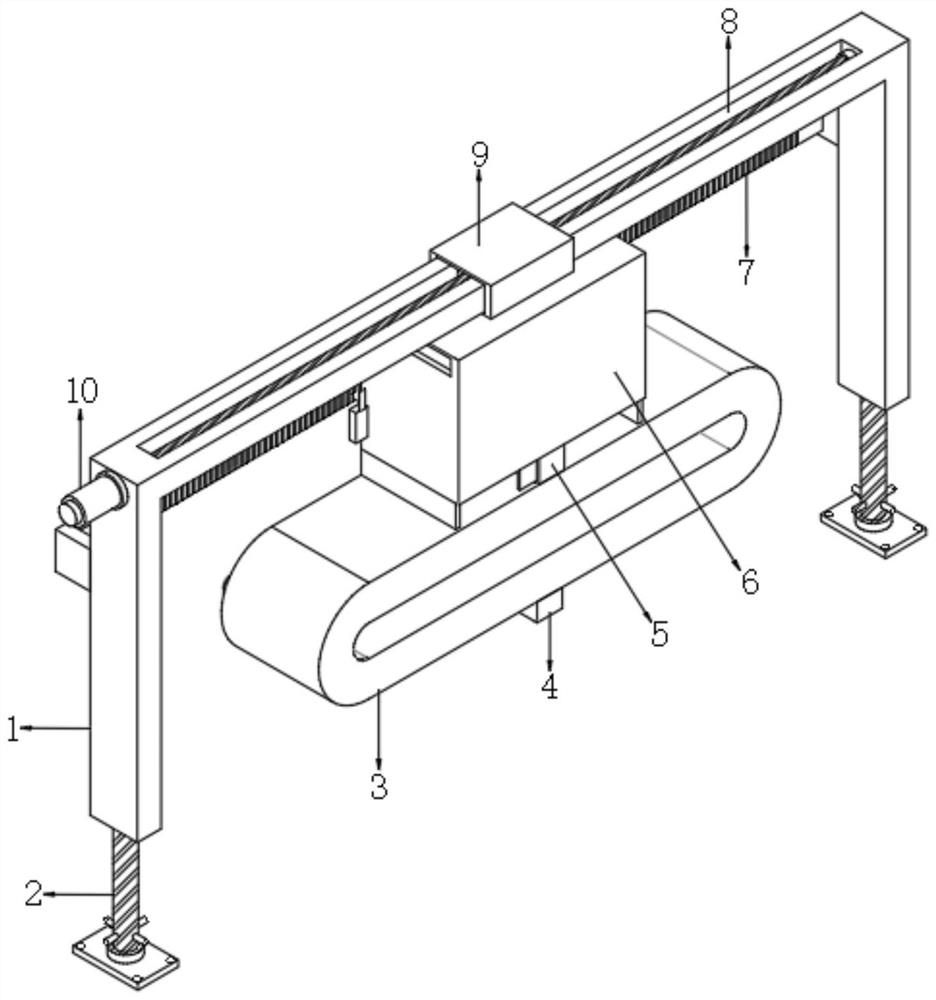

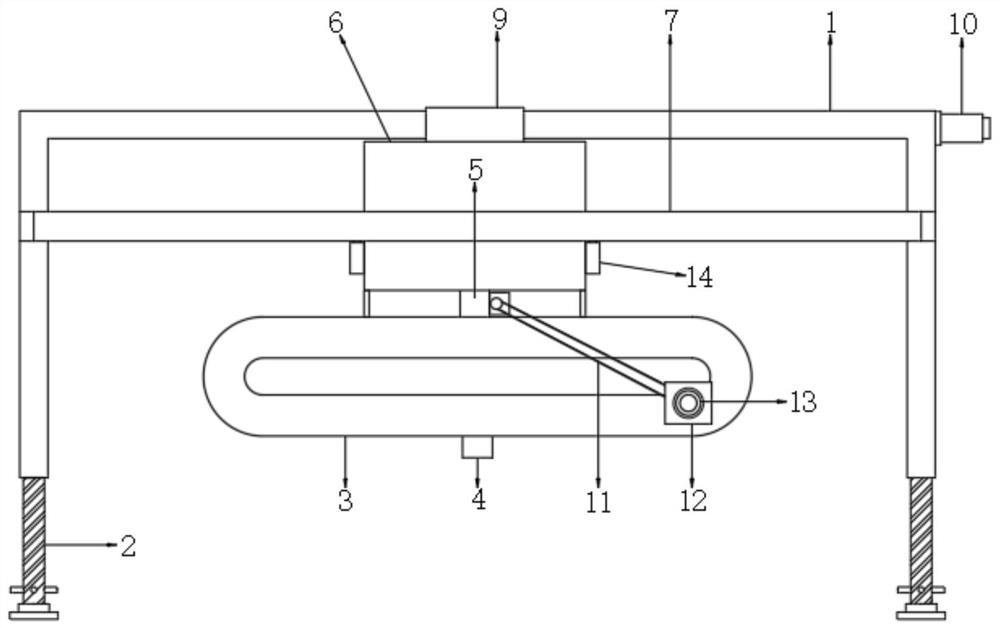

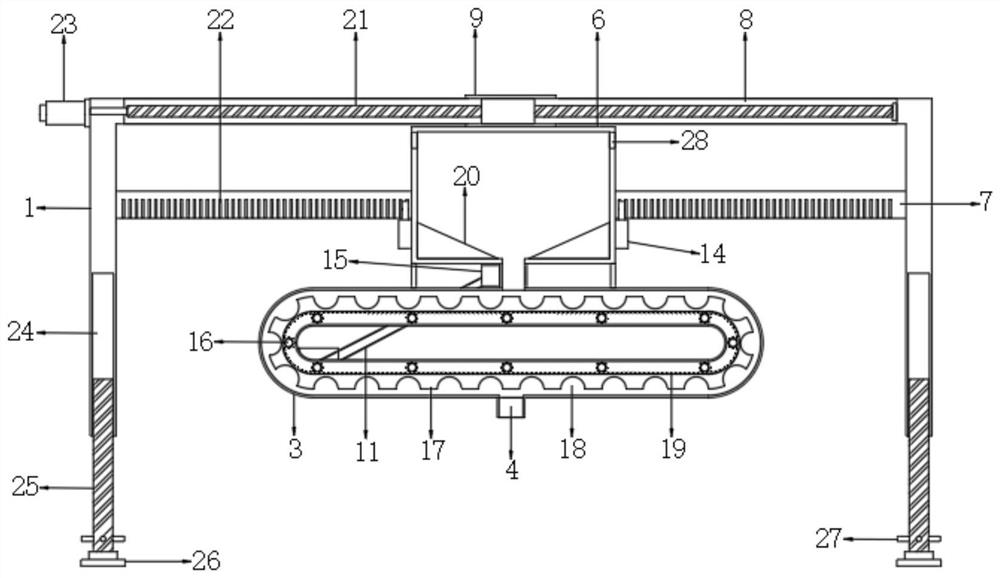

[0032] An automatic feeding device for CNC machine tools, such as Figure 1-5As shown, the support frame 1 is included, the top of the support frame 1 is provided with a transverse groove 8, and the inside of the transverse groove 8 is provided with an X-direction displacement mechanism 10, and the X-direction displacement mechanism 10 includes a threaded screw 21, and the two ends of the threaded screw 21 The end and the two ends of the transverse groove 8 are connected by bearings, and the top of one side of the outer wall of the support frame 1 is connected with a forward and reverse motor 23 by bolts, and the output shaft of the forward and reverse motor 23 and one end of the threaded screw 21 pass through Bolt connection, the outer wall of the threaded screw 21 is threadedly connected with a sliding seat, and the top and bottom of the sliding seat are connected with a movable frame 9 sleeved on the periphery of the support frame 1 through bolts, and the bottom of the movab...

Embodiment 2

[0042] An automatic feeding device for CNC machine tools, such as Figure 6 As shown, in order to solve the problem that the metal waste in the welding process is absorbed by the iron block 27; this embodiment makes the following improvements on the basis of embodiment 1: the inner walls on both sides of the storage box 6 near the bottom of the feed port 28 pass through An elastic cloth 33 is connected by bolts, and the elastic cloth 33 is arranged in a multi-layer structure, and a spring bar 34 is connected between both ends of the opposite side of the elastic cloth 33 by bolts.

[0043] In this embodiment, when a rod-type or cylindrical small-sized workpiece is dropped into the material storage box 6 through the feed port 28, the small-sized workpiece that can be made slides gradually to the inside of the material storage box 6 along the top surface of the elastic cloth 33. , in this process, due to the gravity of the workpiece, the elastic cloth 33 presents a stretching and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com