Environment-friendly soft polishing disc and machining process thereof

A soft polishing and processing technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of environmental pollution, low polishing efficiency, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

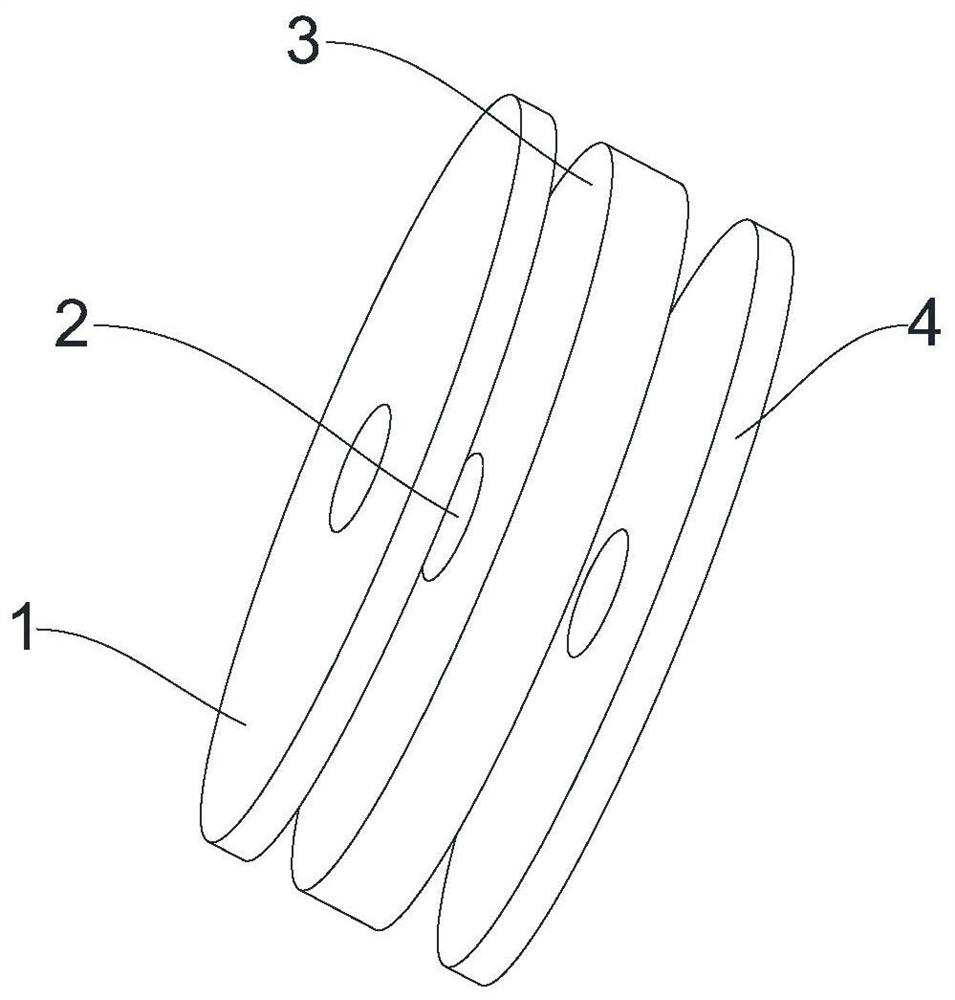

[0043] Please refer to figure 1 , a kind of environment-friendly soft polishing disk that the embodiment of the present application provides, comprises lower film 4, the upper side soft polishing layer 3 of above-mentioned lower film 4, and above-mentioned soft polishing layer 3 is the polyurethane synthetic resin that contains polishing powder, and above-mentioned soft The upper side of the quality polishing layer 3 is provided with an upper backsheet 1 .

[0044] Principle of the present invention: in the polishing process of the polishing disc in the present application, the polishing disc is put into tap water to process industrial electronic products (glass or sapphire, etc.), and the soft polishing layer 3 interacts with the industrial electronic products On the one hand, because the soft polishing layer 3 contains polishing powder, there is no need to add polishing powder, which reduces the polishing process steps and improves the efficiency during the polishing process...

Embodiment 2

[0058] A processing technology of an environment-friendly soft polishing disc, comprising the following steps:

[0059] Preparation of processing tools: table, drying box, scissors, Velcro, polyester fiber sheet, upper mold, lower mold, polishing powder, batching bucket, polyester synthetic resin containing HC8968 and HC8552;

[0060] Production of the upper film 1: Lay the polyester fiber sheet flat on the table, place the lower mold on the upper side of the polyester fiber sheet, and cut out the upper film 1 with the same outline as the lower mold along the side of the lower mold;

[0061] The making of lower film 4: Lay the Velcro flat on the table, place the lower mold on the upper side of the Velcro, cut out the lower film 4 with the same profile as the lower mold along the side of the lower mold, and make the shaped lower film The bottom sheet 4 is fixedly connected with the lower mold;

[0062] Ingredients for the soft polishing layer 3: add polishing powder, polyester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com