A molding die for plastic drainage pipes

A technology for forming molds and drainage pipes, which is applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve the problems of difficult to produce plastic drainage pipes, and achieve the effect of reducing the probability of failure and increasing the connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

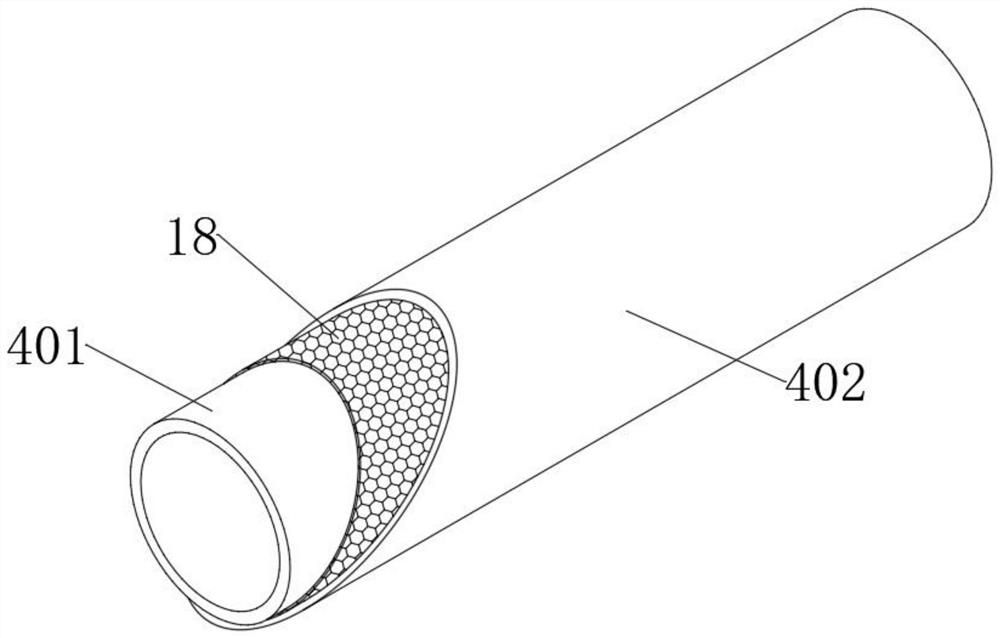

[0039] see Figure 1-6 , a molding die of a plastic drainage pipe, the plastic drainage pipe includes a plastic pipe 4, the plastic pipe 4 includes an inner lining pipe 401 and an outer covering pipe 402, the outer covering pipe 402 is sleeved on the outer side of the inner lining pipe 401, and the inner lining pipe Attachment mesh 18 is connected between 401 and the outer covering pipe 402, and the attachment mesh 18 is respectively fixedly connected with the inner lining pipe 401 and the outer covering pipe 402;

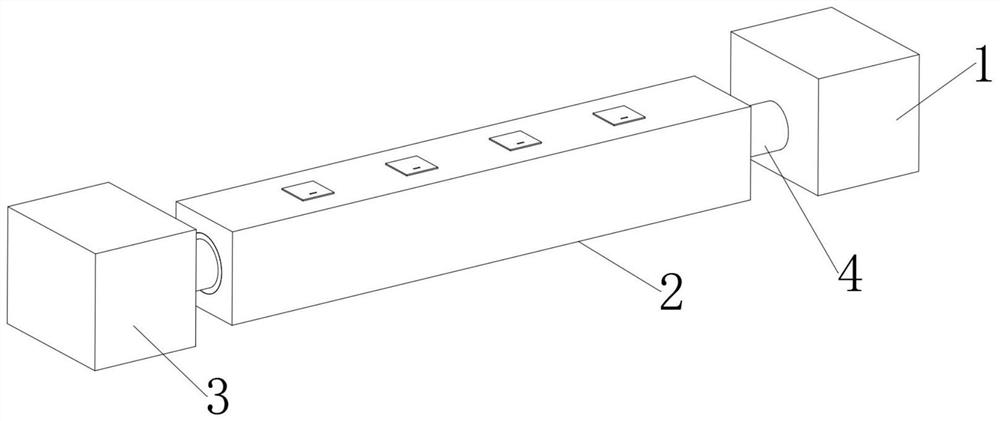

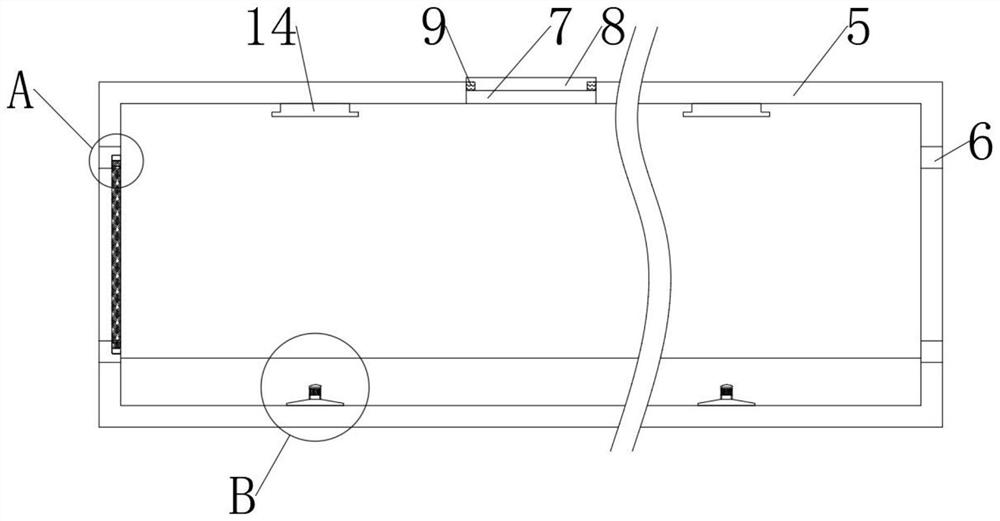

[0040] The molding die includes three parts: extrusion device 1, water cooling chamber 2 and cutting device 3. The plastic tube 4 is extruded by the extrusion device 1 to form a blank, then cooled, formed and hardened in the water cooling chamber 2, and then cut by the cutting device 3. To the desired length, the special inner lining tube 401 and the outer covering tube 402 are produced separately through the above steps, and then are produced by hot pressing. fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com