A kind of boron-doped graphene reinforced copper-based composite material and preparation method thereof

A copper-based composite material and a composite material technology are applied in the field of boron-doped graphene reinforced copper-based composite materials and their preparation, which can solve problems such as the decrease of electrical conductivity, improve mechanical strength and electrical conductivity, realize tight connection, increase Combining the effects of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

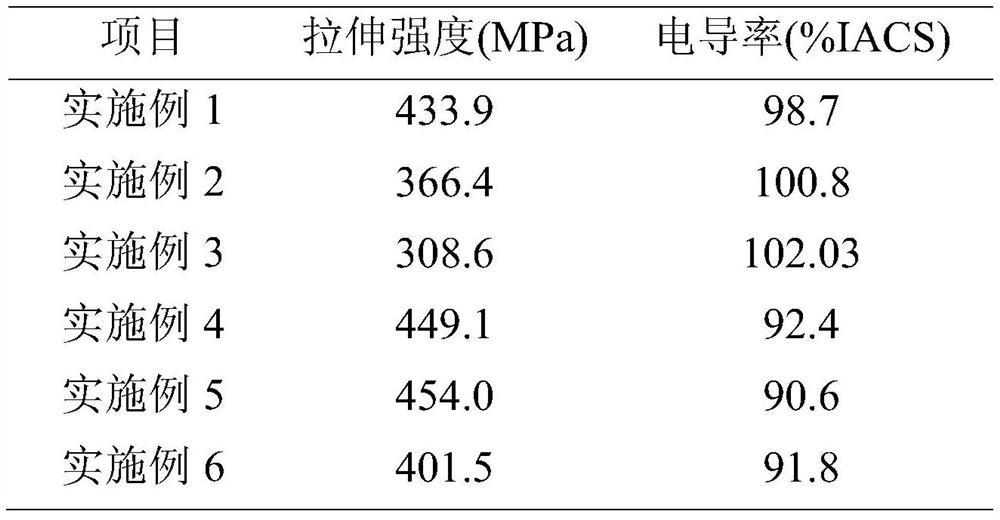

Embodiment 1

[0041] In this embodiment, the boron-doped graphene-reinforced copper-based composite material includes a copper substrate and boron-doped graphene uniformly distributed in the copper substrate. The boron-doped graphene is doped with boron on the graphene sheet, and Cu-B-C bonds are formed between the graphene and the copper substrate.

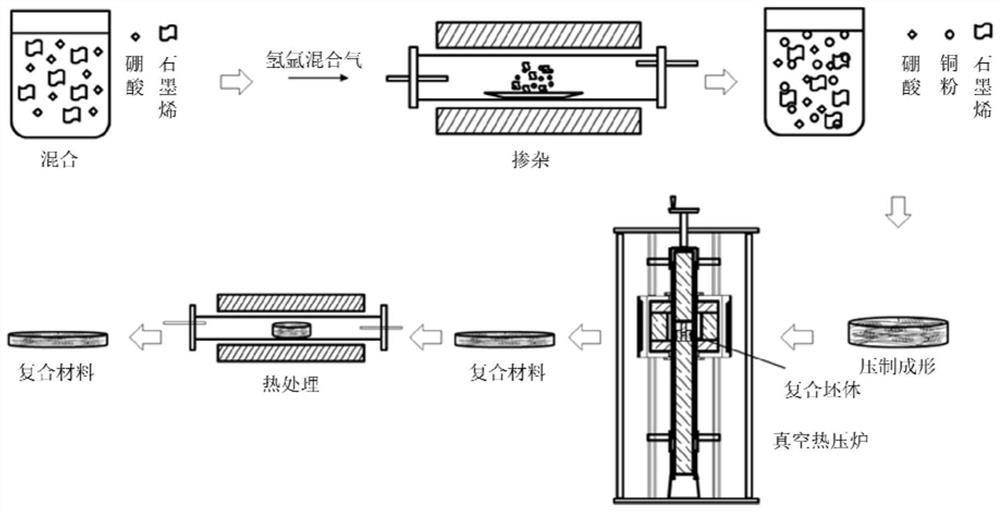

[0042] The preparation method of boron-doped graphene reinforced copper-based composite material in the present embodiment ( figure 1 shown), the steps are as follows:

[0043] (1) Preparation of boron-doped graphene

[0044] Boric acid is dissolved in ethanol, then add graphene and mix, obtain graphene / boric acid mixed solution, the mass ratio of described boric acid and graphene is 1:1, and graphene sheet size is 30-50 μ m, sheet layer 2- 3 floors;

[0045] Filter the graphene / boric acid mixed solution to obtain a solid mixture; place the solid mixture in a hydrogen-argon gas mixture, wherein hydrogen accounts for 5 vol%, raise the temper...

Embodiment 2

[0051] In this embodiment, the boron-doped graphene-reinforced copper-based composite material includes a copper substrate and boron-doped graphene uniformly distributed in the copper substrate. The boron-doped graphene is doped with boron on the graphene sheet, and Cu-B-C bonds are formed between the graphene and the copper substrate.

[0052] The preparation method of boron-doped graphene reinforced copper-based composite material in the present embodiment, the steps are as follows:

[0053] (1) Preparation of boron-doped graphene

[0054] Boric acid is dissolved in ethanol, then add graphene and mix, obtain graphene / boric acid mixed solution, the mass ratio of described boric acid and graphene is 3:1, and graphene sheet size is 30-50 μ m, sheet layer 2- 3 floors;

[0055] Filter the graphene / boric acid mixture to obtain a solid mixture; place the solid mixture in a hydrogen-argon gas mixture, wherein hydrogen accounts for 5 vol%, raise the temperature to 1000° C. and keep...

Embodiment 3

[0061] In this embodiment, the boron-doped graphene-reinforced copper-based composite material includes a copper substrate and boron-doped graphene uniformly distributed in the copper substrate. The boron-doped graphene is doped with boron on the graphene sheet, and Cu-B-C bonds are formed between the graphene and the copper substrate.

[0062] The preparation method of boron-doped graphene reinforced copper-based composite material in the present embodiment, the steps are as follows:

[0063] (1) Preparation of boron-doped graphene

[0064] Boric acid is dissolved in ethanol, then add graphene and mix, obtain graphene / boric acid mixed solution, the mass ratio of described boric acid and graphene is 5:1, and graphene sheet size is 30-50 μ m, sheet layer 2- 3 floors;

[0065] Filter the graphene / boric acid mixture to obtain a solid mixture; place the solid mixture in a hydrogen-argon gas mixture, wherein hydrogen accounts for 5 vol%, raise the temperature to 1100°C and keep i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com