Novel robot hot galvanizing device

A robot and hot-dip galvanizing technology, applied in the field of industrial manufacturing, can solve the problems of only about 35-45 tons, slow action rhythm, large floor space, etc., to avoid waste, low failure rate, and short distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

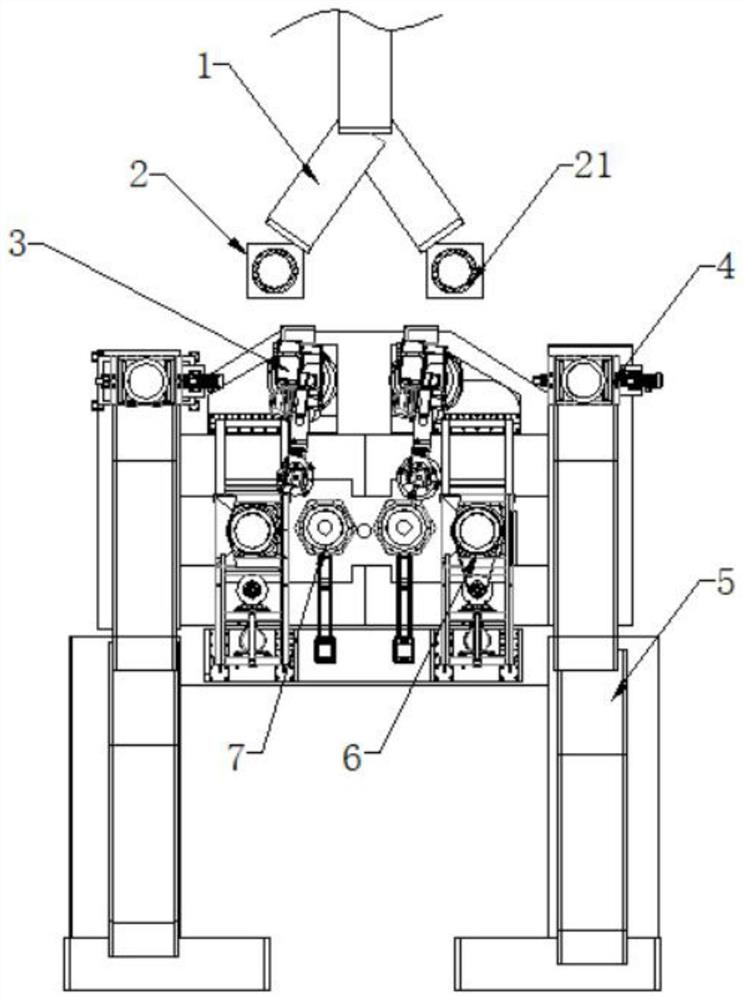

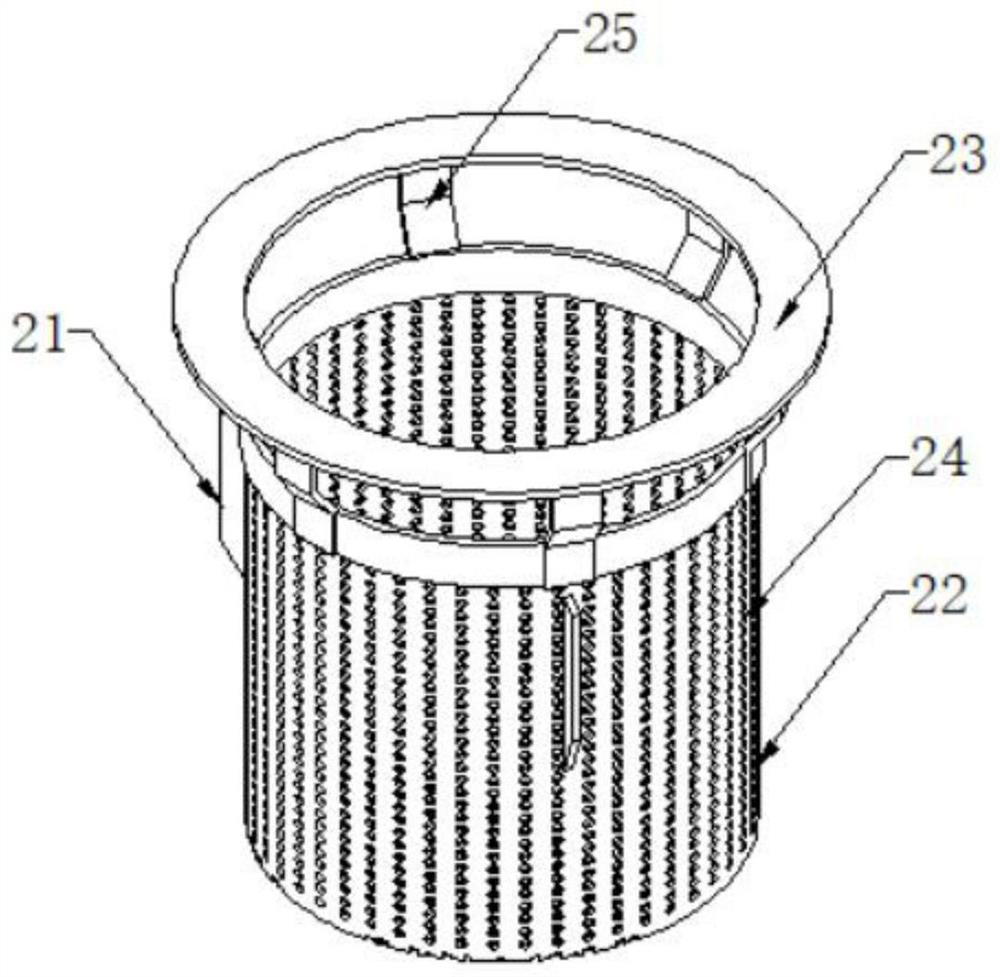

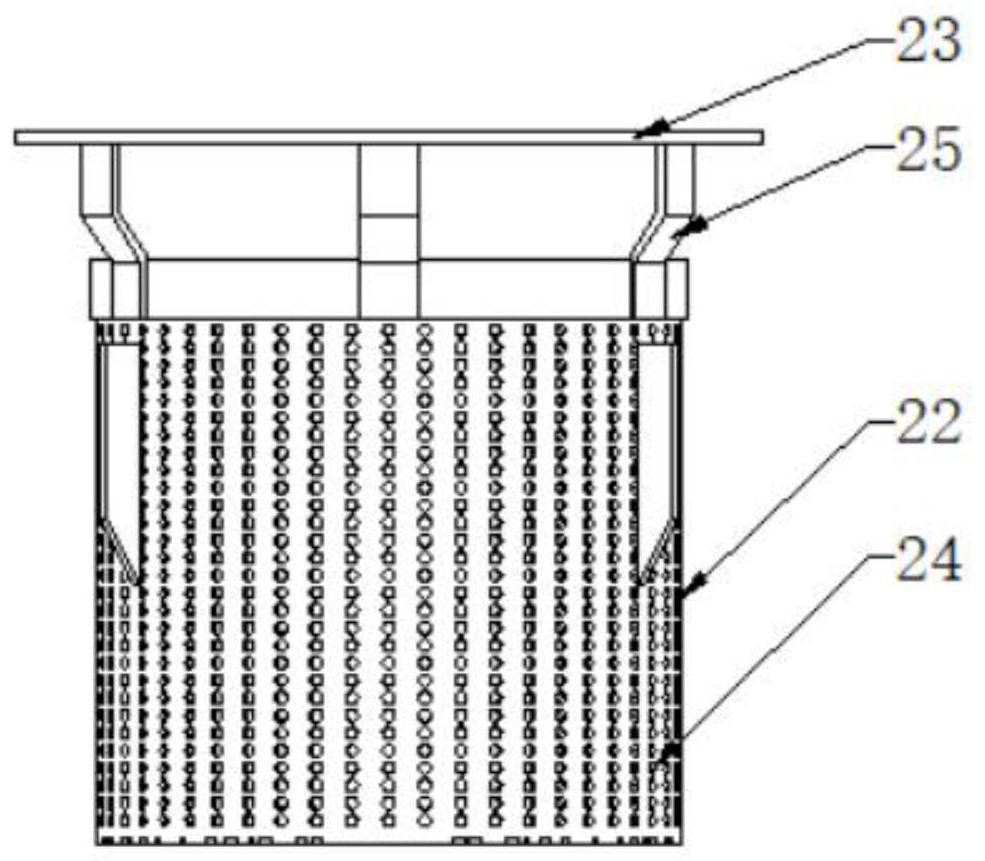

[0045] Such as Figure 1-20 As shown, the present invention provides a novel robot hot-dip galvanizing device, comprising an incoming material conveying line 1, a blanking cooling line 5 and a weighing loading platform 2, and the end of the incoming material conveying line 1 is divided into two parts, and respectively extended To the obliquely above the weighing and feeding platform 2, a material frame 21 is placed on the inner top surface of the weighing and feeding platform 2, and a robot gripper 3 is arranged behind the weighing and feeding platform 2, and both sides of the robot gripper 3 are arranged There is an overturning and unloading mechanism 4, and the bottom side of the overturning and unloading mechanism 4 is provided with a blanking cooling line 5, and a bridge centrifugal mechanism 6 is arranged between the unloading cooling lines 5, and a soaking lift is arranged between the bridge centrifugal mechanisms 6. Institution7.

[0046] Further, the material frame 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com