Temperature sensor response time testing device

A temperature sensor and testing device technology, applied in the field of sensor testing, can solve problems such as difficult enterprise application, and achieve the effects of reducing the influence of human factors, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

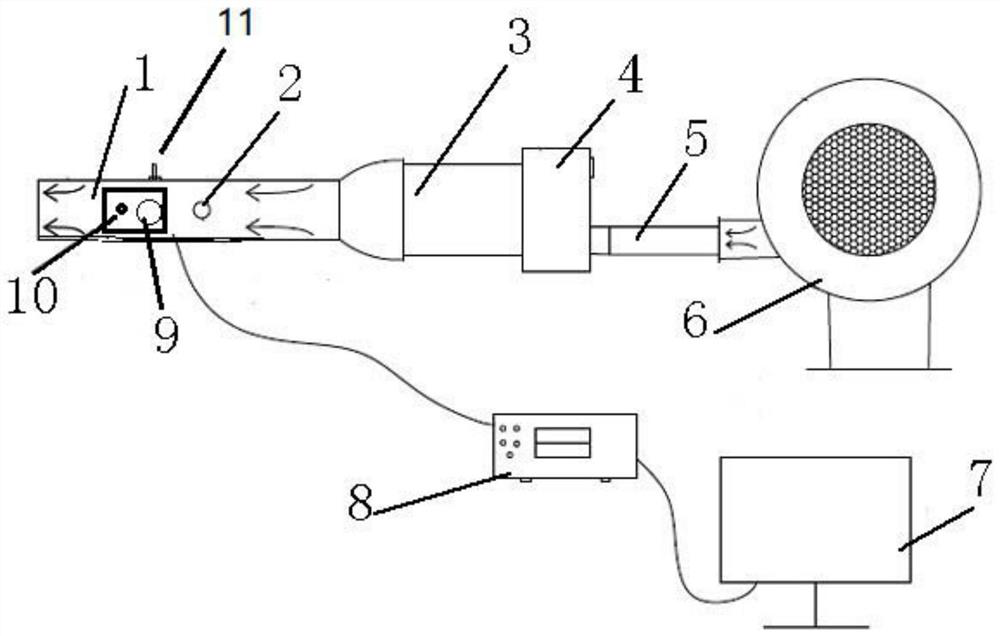

[0012]The present invention will be further described below with reference to the accompanying drawings.

[0013]according tofigure 1The present invention is a temperature sensor response time test device including a test chamber 1, an electric heater 4, a blower 6, and a computer 7, and an exhaust port is provided on the test chamber 1, and there is an extension on the exhaust port. The tube also includes a drive device 9, the driving device 9 including a cylinder and a PLC controller, the computer 7 is disposed on the test chamber 1 side, and the computer 7 is also connected to a resistor 8, the resistor 8 pass The cable is connected to the computer 7 and the temperature sensor 10, respectively, and the computer 7 has a data acquisition processing system, and the temperature sensor 10 extends into the test chamber 1 by an extension tube, and a fixed slot is also provided on the drive device 9. The temperature sensor 10 extends into the fixed groove.

[0014]Further, the electric heater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com