Chip detection method, electronic equipment and storage medium

A technology for chip detection and chip-to-be-test, which is applied in measuring devices, optical testing of flaws/defects, and material analysis through optical means, and can solve problems such as reducing the efficiency of defect analysis and processing, unrecognizable defects, and indistinct features of defects , to achieve the effect of improving processing efficiency, improving efficiency, and reducing data collection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

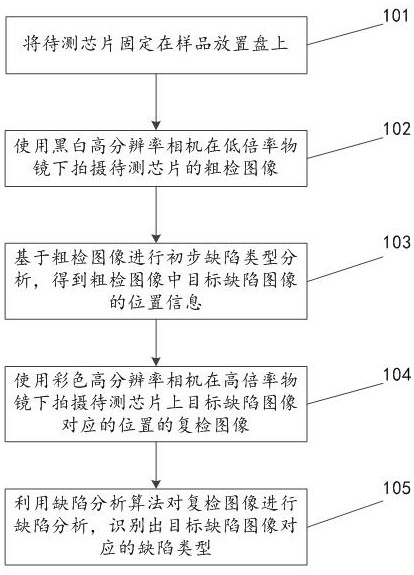

[0052] figure 1 It is a schematic flowchart of Embodiment 1 of the chip detection method shown in the embodiment of the present application.

[0053] see figure 1 , Embodiment 1 of the chip detection method in the embodiment of the present application includes:

[0054] 101. Fix the chip to be tested on the sample placement plate;

[0055] The chip to be tested is an LED chip, which can be a traditional LED chip, a mini LED chip or a micro LED chip, and is especially suitable for a micro LED chip.

[0056] The sample placement plate is used to fix the LED chip to be tested, and can drive the LED chip to be tested to move quickly, and prevent the chip to be tested from shifting during the moving process, that is, to prevent the chip to be tested from being relative to the sample placement plate. The position changes; the surface of the sample placement plate can be treated with black frosting to prevent reflection from affecting imaging.

[0057] In this embodiment, the way...

Embodiment 2

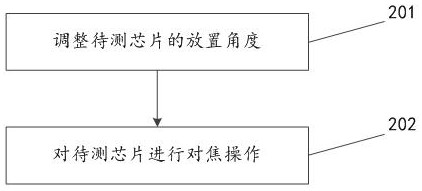

[0080] In order to facilitate understanding, an embodiment of the chip detection method is provided below for description. In the first embodiment above, after the chip to be tested is fixed on the sample placement plate, it is necessary to adjust the placement angle of the chip to be tested and complete the focusing operation. In order to ensure the effect of subsequent image capture.

[0081] figure 2 It is a schematic flowchart of Embodiment 2 of the chip detection method shown in the embodiment of the present application.

[0082] see figure 2 , Embodiment 2 of the chip detection method in the embodiment of the present application includes:

[0083] 201. Adjust the placement angle of the chip to be tested;

[0084] Adjust the angle so that the long and short sides of the chip to be tested are parallel to the XY axis of the camera. It can be that the long side of the chip to be tested is parallel to the X axis of the camera, and the short side is parallel to the Y axis...

Embodiment 3

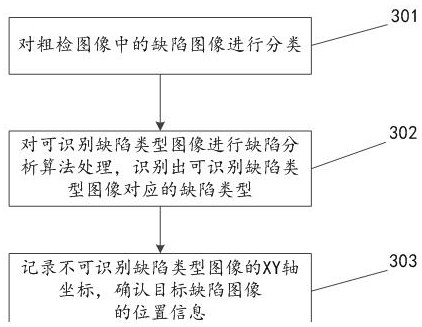

[0099] For ease of understanding, an example of the chip inspection method is provided below for illustration. In the first embodiment above, the preliminary defect type analysis based on the rough inspection image needs to classify the defect images in the rough inspection image, and classify images are processed differently.

[0100] image 3 It is a schematic flowchart of Embodiment 3 of the chip detection method shown in the embodiment of the present application.

[0101] see image 3 , Embodiment 3 of the chip detection method in the embodiment of the present application includes:

[0102] 301. Classify the defect images in the rough inspection images;

[0103] A deep convolutional neural network algorithm is used to classify the defect images in the rough inspection images into identifiable defect type images and unrecognizable defect type images.

[0104] The deep convolutional neural network algorithm is a kind of feed-forward neural network algorithm that includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com