Fire extinguishing system

A fire extinguishing system and fire extinguishing agent technology, applied in the field of fire extinguishing systems, can solve the problems of delayed fire extinguishing timing, failure to cover fire extinguishing foam spray, etc., and achieve the effect of rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

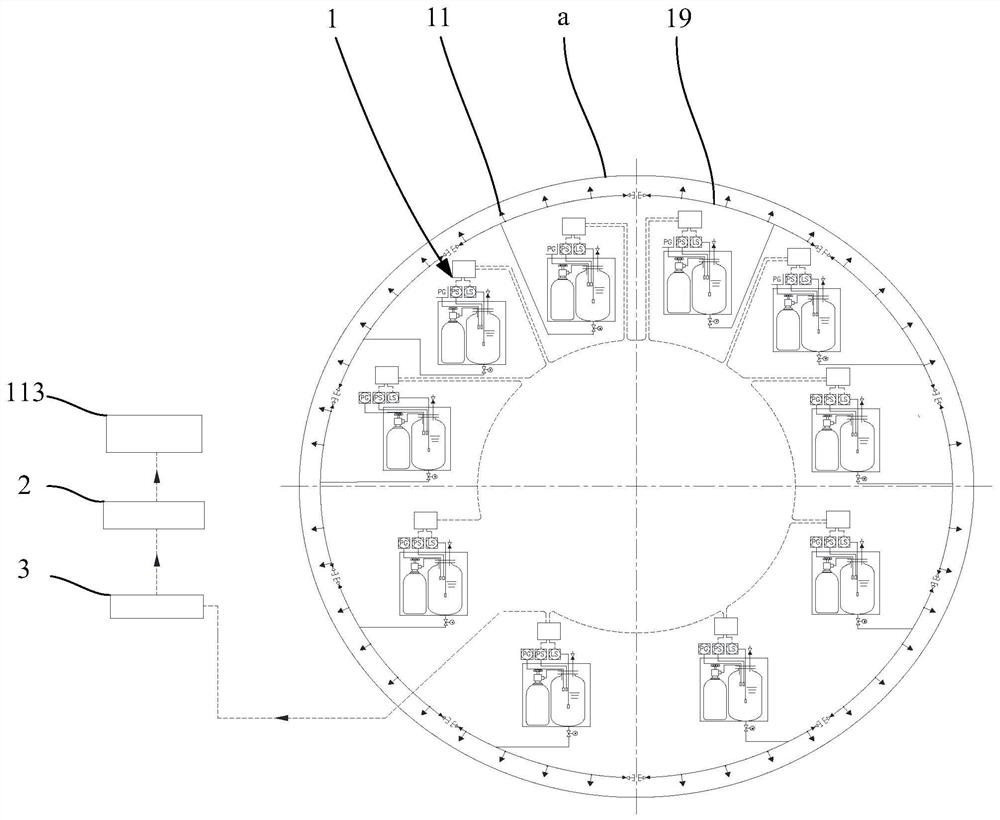

[0026] figure 1 It is a structural schematic diagram of a fire extinguishing system provided by an embodiment of the present disclosure. Such as figure 1 As shown, the fire extinguishing system includes a plurality of fire extinguishing devices 1, and the plurality of fire extinguishing devices 1 are arranged at intervals in the circumferential direction on the floating plate a of the outer floating roof oil storage tank.

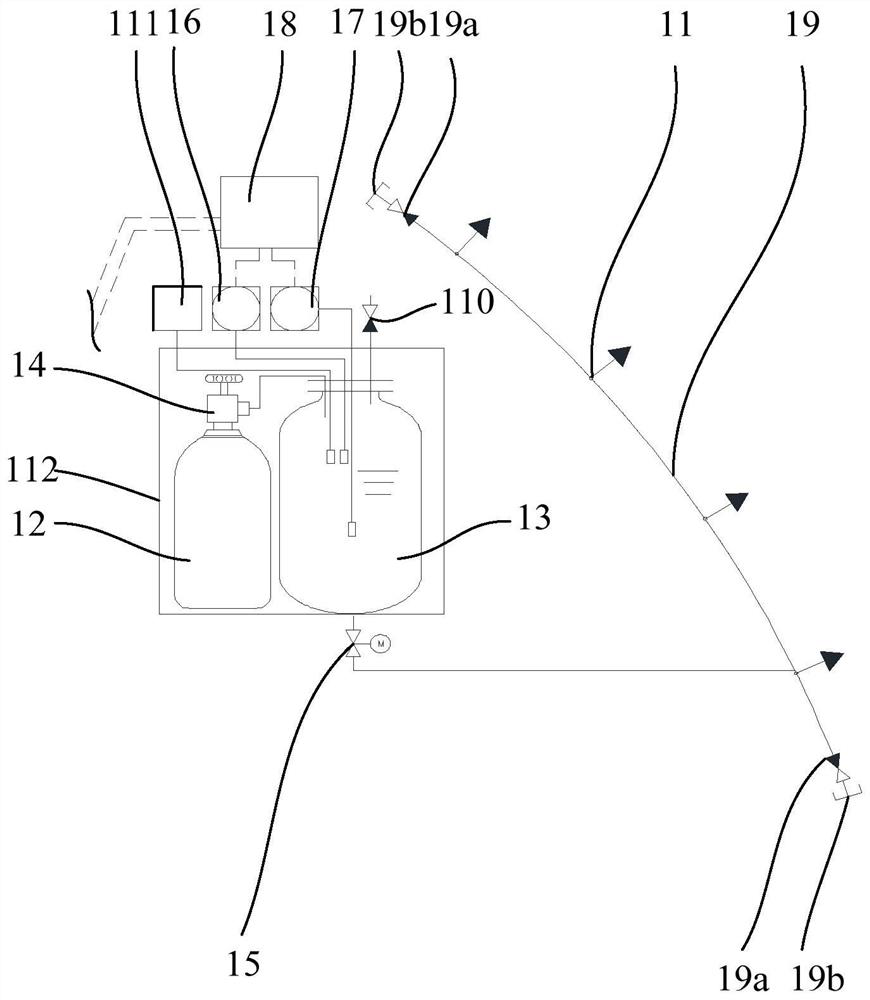

[0027] figure 2 It is a structural schematic diagram of a fire extinguishing device provided by an embodiment of the present disclosure. Such as figure 2 As shown, the fire extinguishing device 1 includes:

[0028] Multiple closed nozzles 11, pressurized gas storage bottle 12, fire extinguishing agent sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com