Glass kiln desulfurization and denitration tower

A technology of desulfurization, denitrification, and kiln furnace, which is applied in the field of flue gas purification, and can solve problems such as excessive energy, inability to process in time, automatic cleaning inside the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

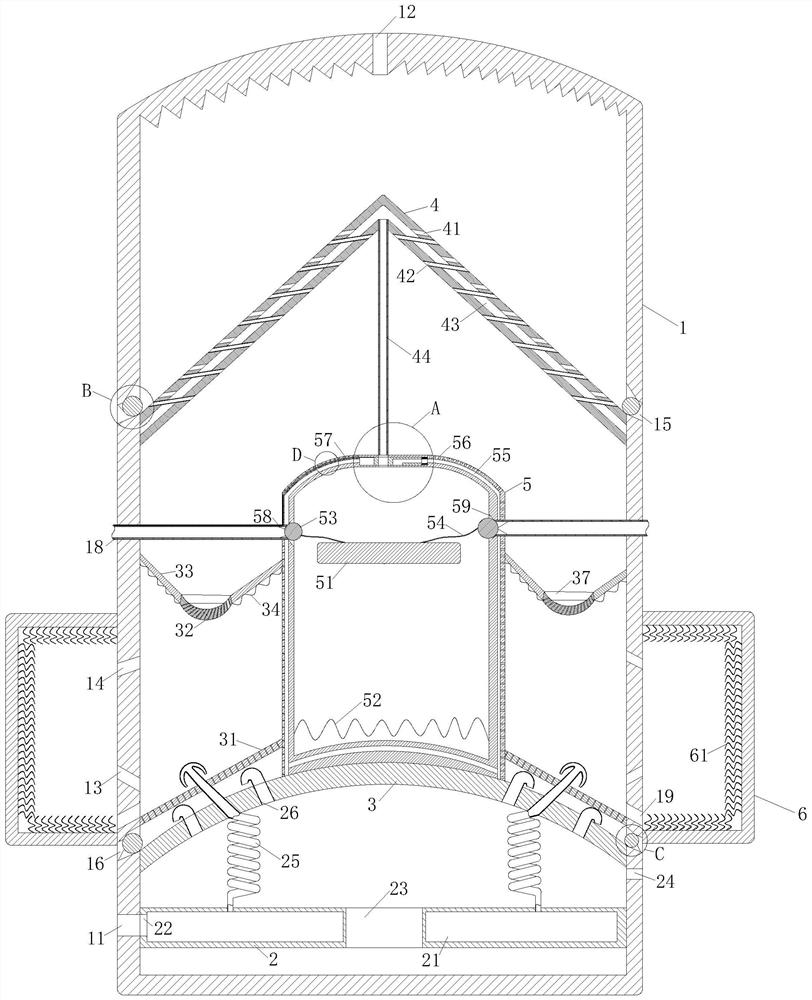

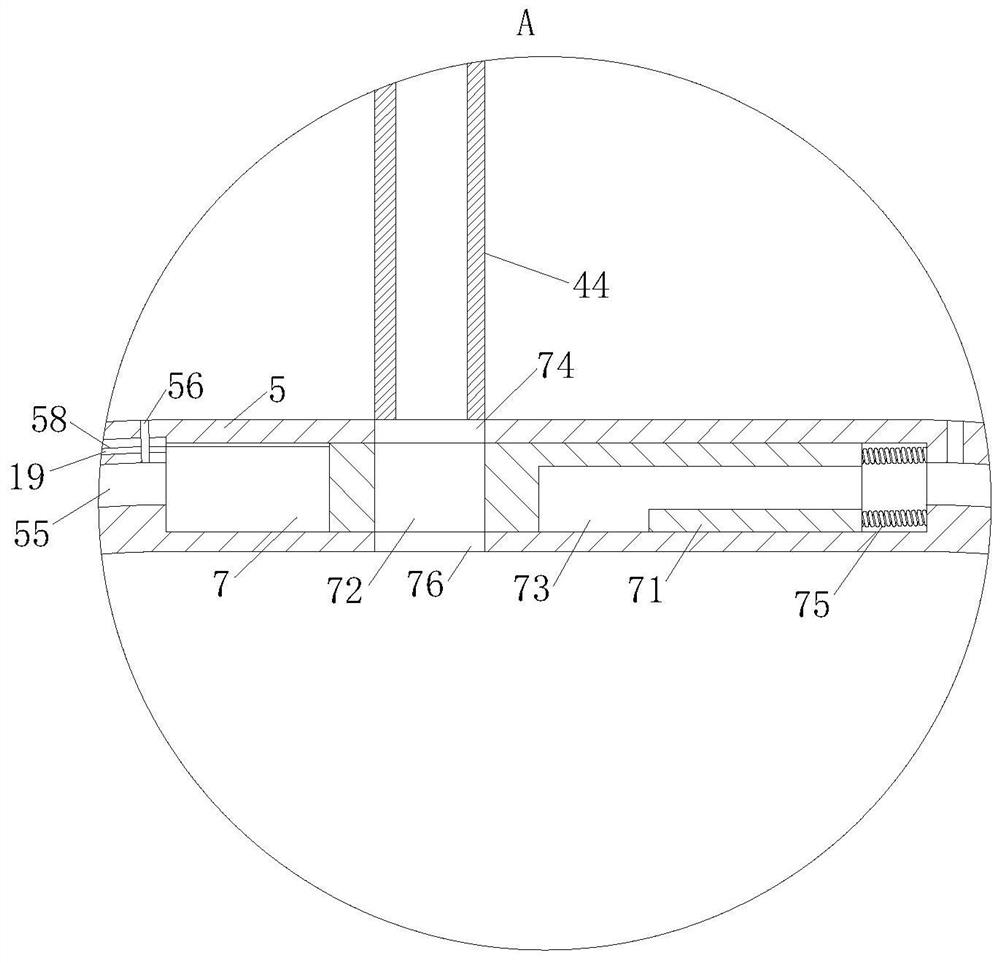

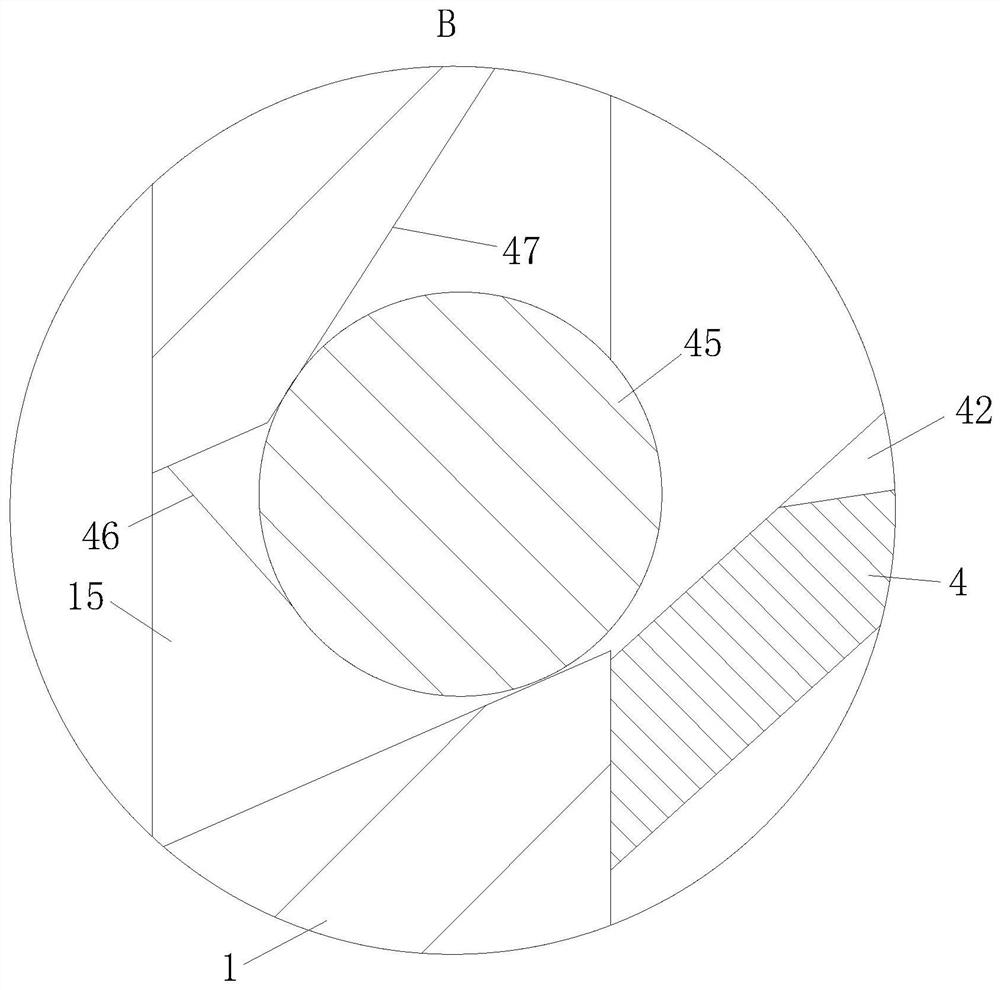

[0026] As an embodiment of the present invention, the first filter 31 having a annular design between the water tank 5 and the inner wall of the tower body 1; the first filter 31 is inclined by the inner wall of the tank 5 toward the tower body 1 Designed, and the hook tube 26 is located below the first filter 31; the inner wall of the tower body 1 is connected to the first filter 31 in the inner wall of the tower body 1, uniformly open a slaglet 19; the helical pipe 25 end ship anchor The shape is designed and passed through the second separator 3 and the first filter 31; the helical conduit 25 is directed through the direction of the first filter 31 to the first filter 31; the tower body 1 Uniform solid dust box 6; the tower body 1 side wall uniformly opens the second intake port 13 and the second air port 14 to connect the dust box 6 inner space; the second air port 14 is located in the second On the upper side of the air inlet 13; the second intake port 13 is designed by the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com