A kind of antibacterial self-healing microcapsule and its preparation method and application in coating

A self-healing microcapsule and self-healing technology, which is applied in the direction of microcapsule preparation, microsphere preparation, antifouling/underwater coating, etc., can solve the problems of poor product storage, poor compatibility, and microcapsule agglomeration, and achieve improved storage High stability, reduced agglomeration, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

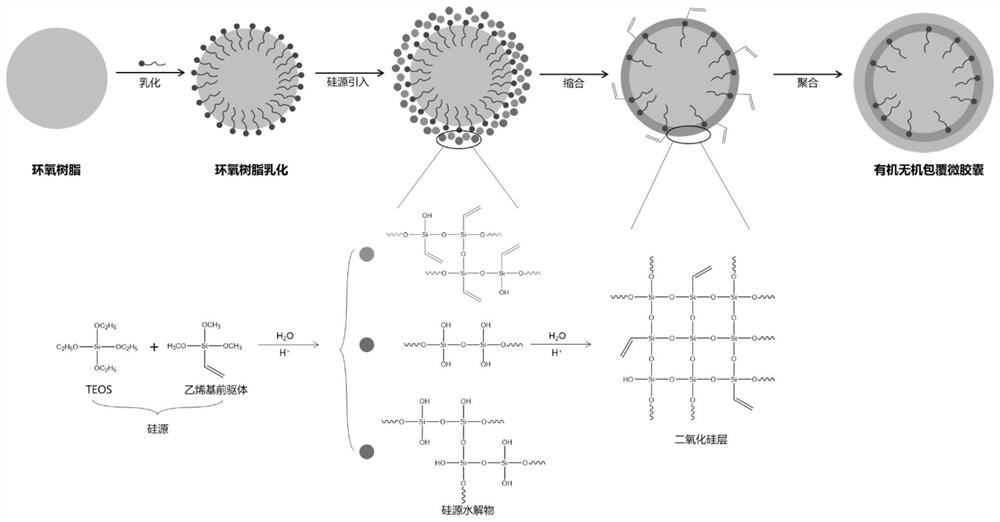

[0036] The present invention also provides the preparation method of the above-mentioned antibacterial self-healing microcapsules, which comprises the following steps:

[0037] S1 adds the self-healing substance to the emulsifier to obtain a mixture;

[0038] S2 adds the silicon source material to the obtained mixture after hydrolysis with acid conditions, to form inorganic microcapsules with inorganic shell layers covering the self-healing material;

[0039] S3 emulsion-polymerizes the obtained inorganic microcapsules with acrylic monomers to obtain the antibacterial self-healing microcapsules.

[0040] like figure 1 As shown in the present invention, after the self-healing substance is emulsified by an emulsifier in advance, the emulsifier coats the self-healing substance; The emulsifier covered with the self-healing substance undergoes interfacial condensation to form a silica inorganic shell layer; at this time, the silica shell layer contains vinyl active groups, and th...

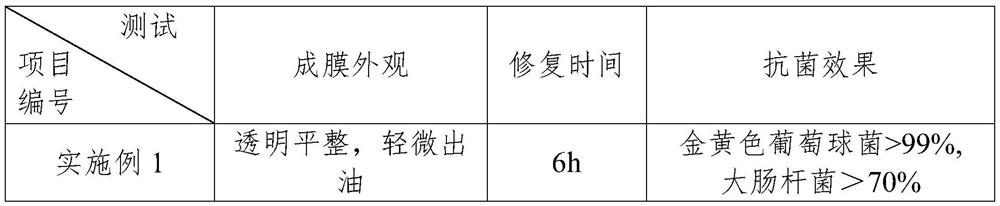

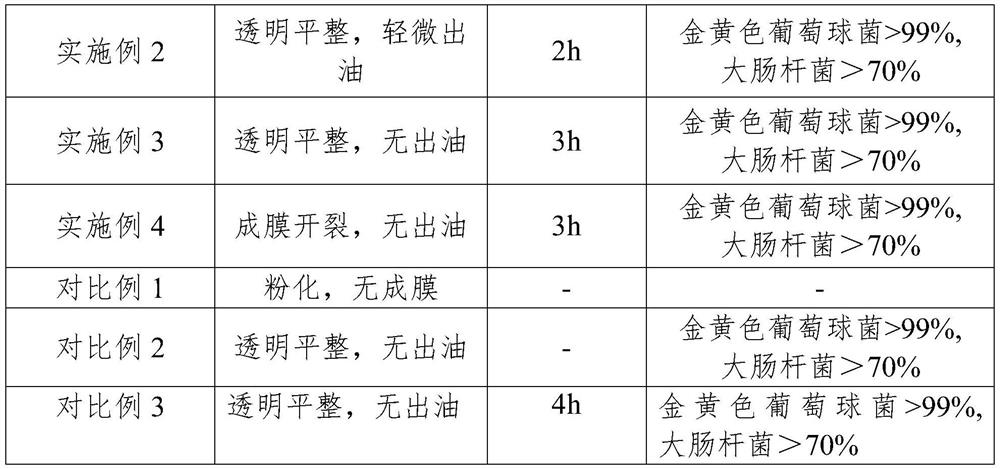

Embodiment 1

[0048] Preparation of antibacterial self-healing microcapsules:

[0049] Emulsifying mixing of S1 self-healing substances

[0050]Under mechanical dispersion at 1500rpm, add 4g of PF80S (nonionic emulsifier) to 100g of water to form a homogeneous solution; continue to stir at a rotational speed of 3000rpm, add 100g of a mixture of epoxy resin E51 and cationic photoinitiator WPI113 (wherein the initiator and The resin ratio is 1:20), and the mixture is dispersed at high speed for half an hour to form a uniform emulsified mixture.

[0051] S2 silicon source pre-hydrolyzate

[0052] Take 20g of ethyl orthosilicate and 10g of vinyltrimethoxysilane and add it to 70g of water under stirring at 250rpm, slowly add dilute hydrochloric acid (mass concentration of 10%) to adjust the pH of the system to 2.0; continue to stir at 40°C for 30min to form a transparent The silicon source hydrolyzate.

[0053] S3 forms inorganic microcapsules

[0054] S31, under stirring at 250rpm, slowly...

Embodiment 2

[0062] The preparation method of antibacterial self-healing microcapsules, steps and parameters are the same as those in Example 1, the difference is: the epoxy resin in step S1 is replaced by E44, the photoinitiator is WPI113, and the weight ratio of initiator to resin is 1:5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com