A microfabricated gas matching layer modulated bulk ultrasonic cell assembly and arrangement device, preparation method and application

A technology for arrangement devices and matching layers, which is applied in tissue cell/virus culture devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problem that cells cannot be arranged tightly and orderly, and it is difficult to realize arbitrary patterns of cells issues such as globalization, to achieve the effect of huge application prospects and commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

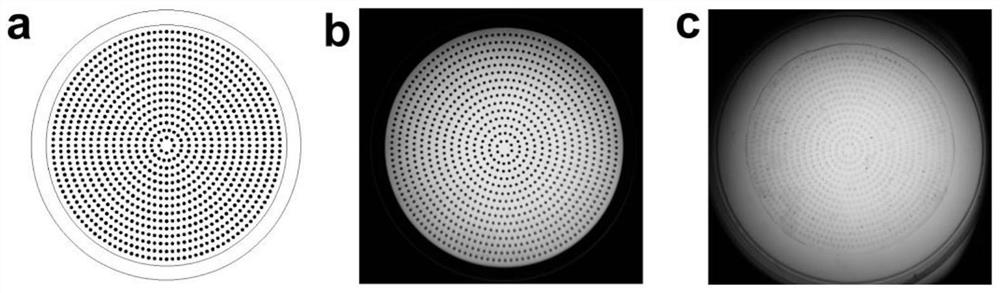

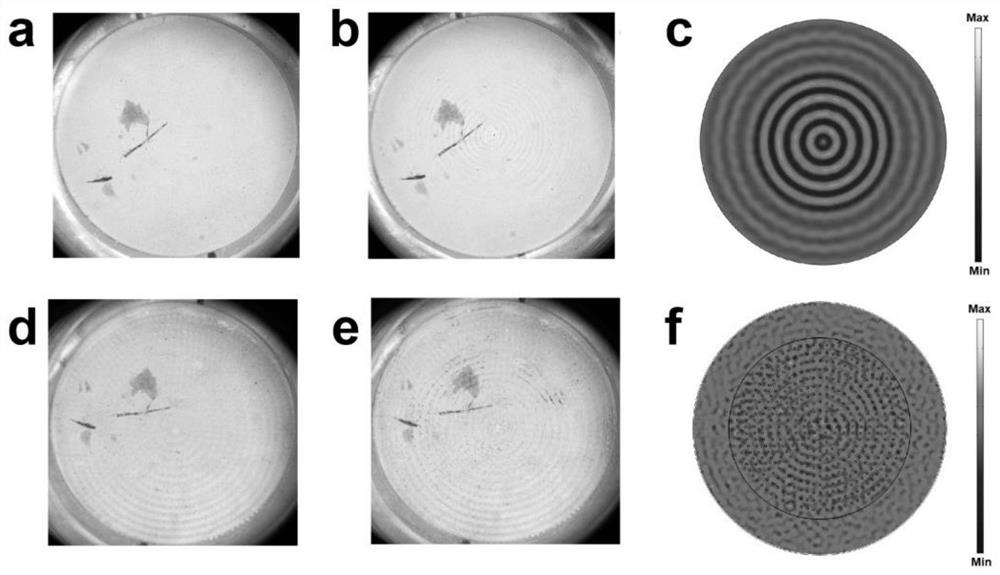

[0043] Example 1 Using soft lithography to process simple patterned acoustic matching layers for assembly and arrangement of polystyrene microspheres

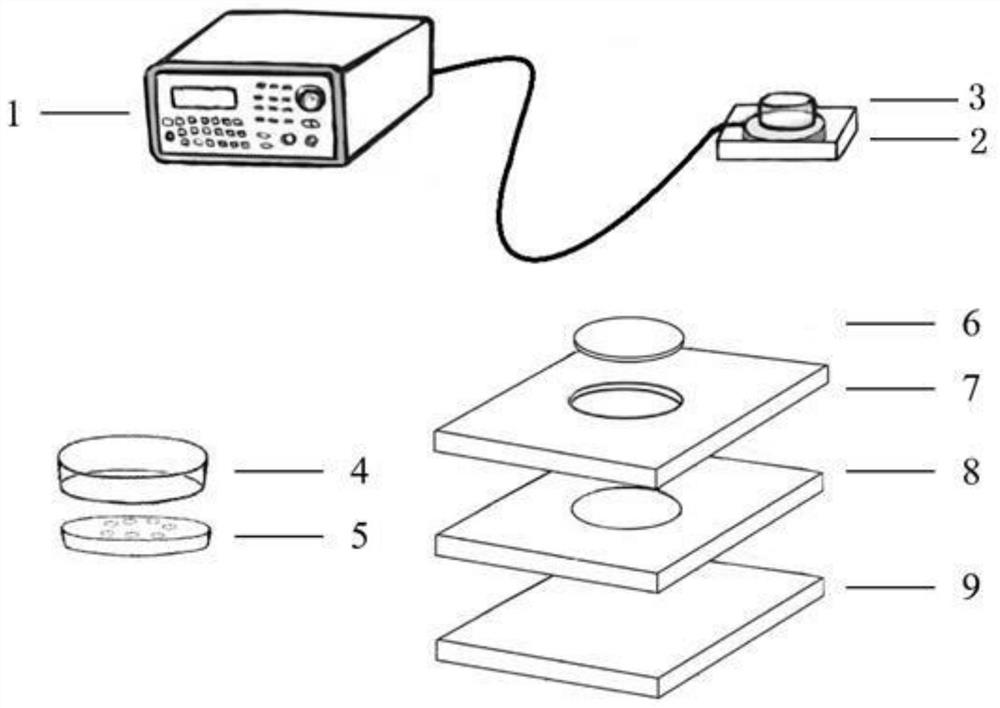

[0044] like figure 1 As shown, the apparatus for assembling and arranging polystyrene microspheres by processing an acoustic matching layer with soft lithography according to an embodiment of the present invention includes an arbitrary waveform function generator 1, a cell assembly chamber 3, a micropatterned structure matching layer 5, and an ultrasonic Transducer 2. In this embodiment, the cell assembly chamber 3 is composed of a cell culture dish 4 , the micro-patterned structure matching layer 5 is located at the outer bottom of the cell culture dish 4 , and the ultrasonic transducer 2 is located at the bottom of the micro-patterned structure matching layer 5 .

[0045] Arbitrary waveform function generator 1 is AFG3000, with a dual-channel design, the maximum sampling rate is 1GS / s, the output frequency is up to 100MHz, a...

Embodiment 2

[0056] Example 2 Using soft lithography to process complex pattern acoustic matching layers for assembly and arrangement of polystyrene microspheres

[0057] like figure 1 As shown, the apparatus for assembling and arranging polystyrene microspheres by processing an acoustic matching layer with soft lithography according to an embodiment of the present invention includes an arbitrary waveform function generator 1, a cell assembly chamber 3, a micropatterned structure matching layer 5, and an ultrasonic Transducer 2. In this embodiment, the cell assembly chamber 3 is composed of a cell culture dish 4 , the micro-patterned structure matching layer 5 is located at the outer bottom of the cell culture dish 4 , and the ultrasonic transducer 2 is located at the bottom of the micro-patterned structure matching layer 5 .

[0058] Arbitrary waveform function generator 1 is AFG3000, with a dual-channel design, the maximum sampling rate is 1GS / s, the output frequency is up to 100MHz, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com