Wind-induced vibration control method for high-pier long-span bridge during construction period

A wind-induced vibration and bridge technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of poor wind resistance and safety of construction personnel, low inherent damping, and small lateral stiffness of beams, etc. Effects of wind safety and construction personnel comfort, reduction of wind vibration response and wind-induced buffeting load, and improvement of lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

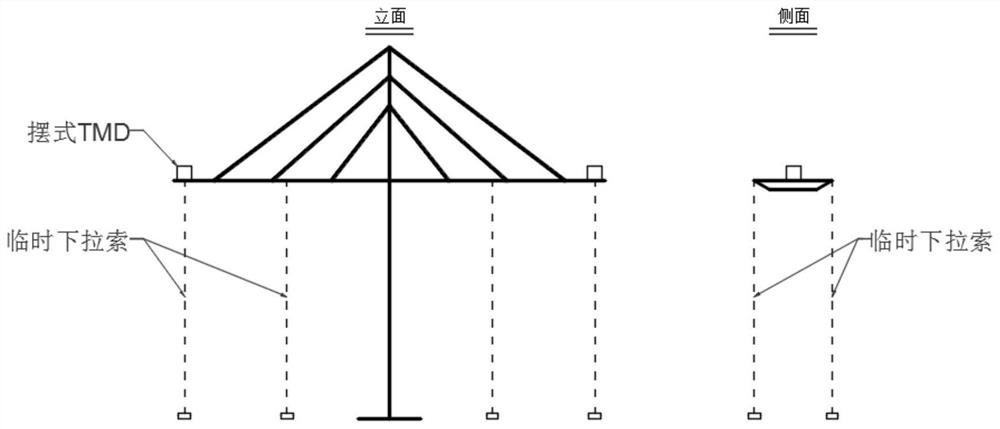

[0061] Example: A wind-induced vibration control method during the construction period of a high-pier long-span bridge, such as figure 1 shown, including the following steps:

[0062] S101: Analyze the dynamic characteristics of the cantilever structure of the main beam of the high-pier long-span bridge during the construction period, and obtain the natural frequency information of the first 20 orders of the main beam at different construction stages;

[0063] S102: Establishing the original finite element model of the construction state of the main girder cantilever of the bridge structure according to the bridge structure design parameters and construction plan data;

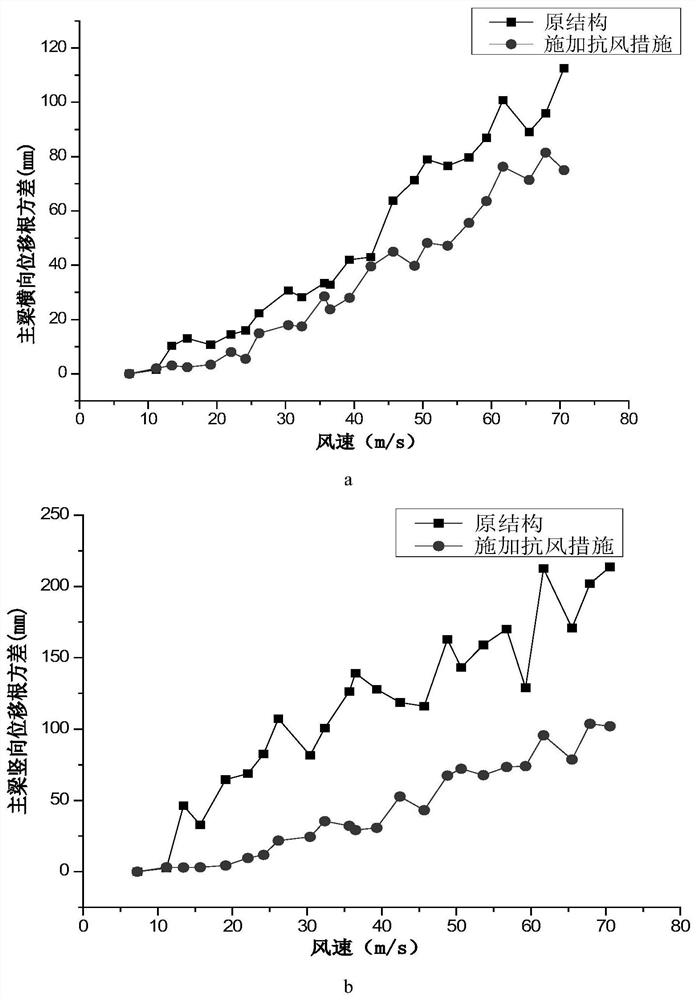

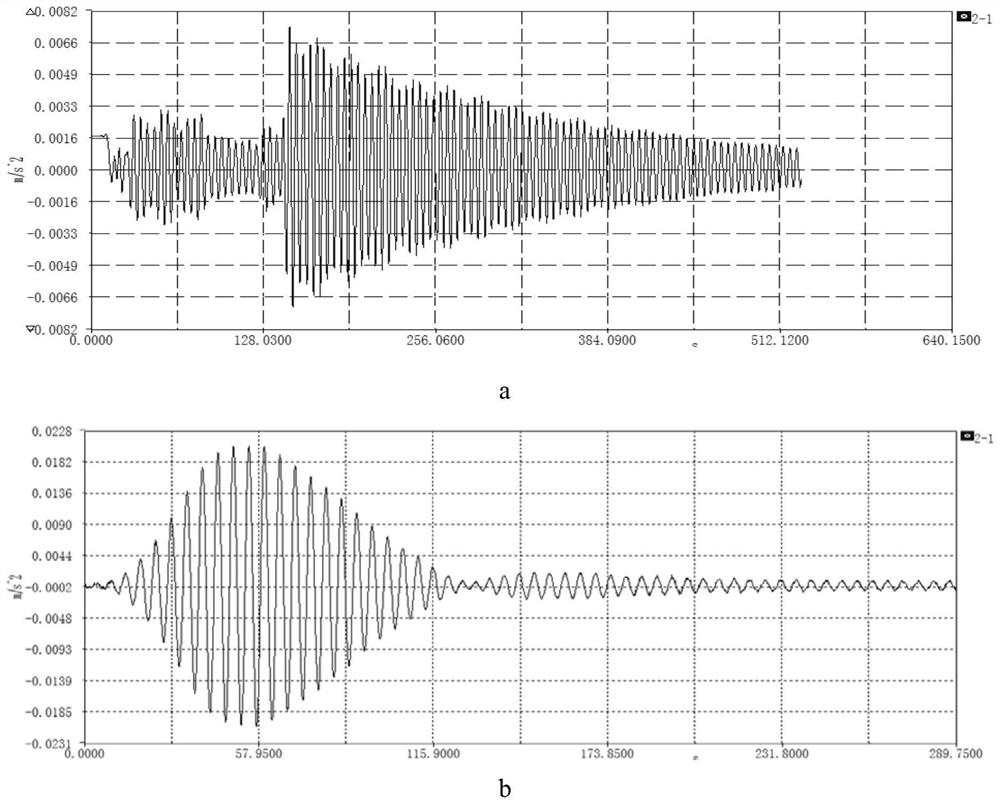

[0064] S103: Obtain the wind resistance measure parameters for the cooperation between the vertical pull cable and the eddy current pendulum TMD, and input the wind resistance measure parameters into the original finite element model to establish the wind resistance finite element model;

[0065] S104: After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com