Test method for simulating partial root zone irrigation through longitudinal water difference distribution

A technology of distribution simulation and test method, applied in the fields of botanical equipment and methods, automatic watering device, application, etc., can solve problems such as being unsuitable for studying cotton water use efficiency, etc., and achieve the effect of convenient observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

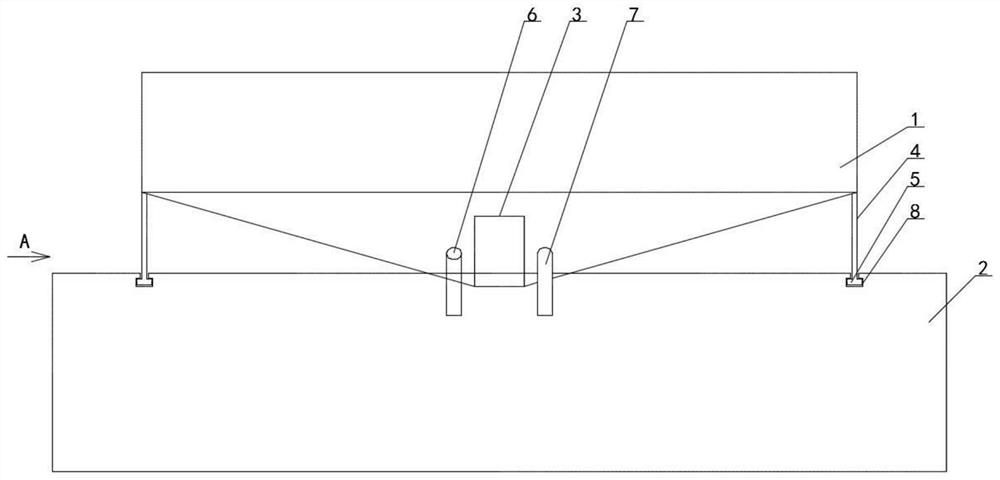

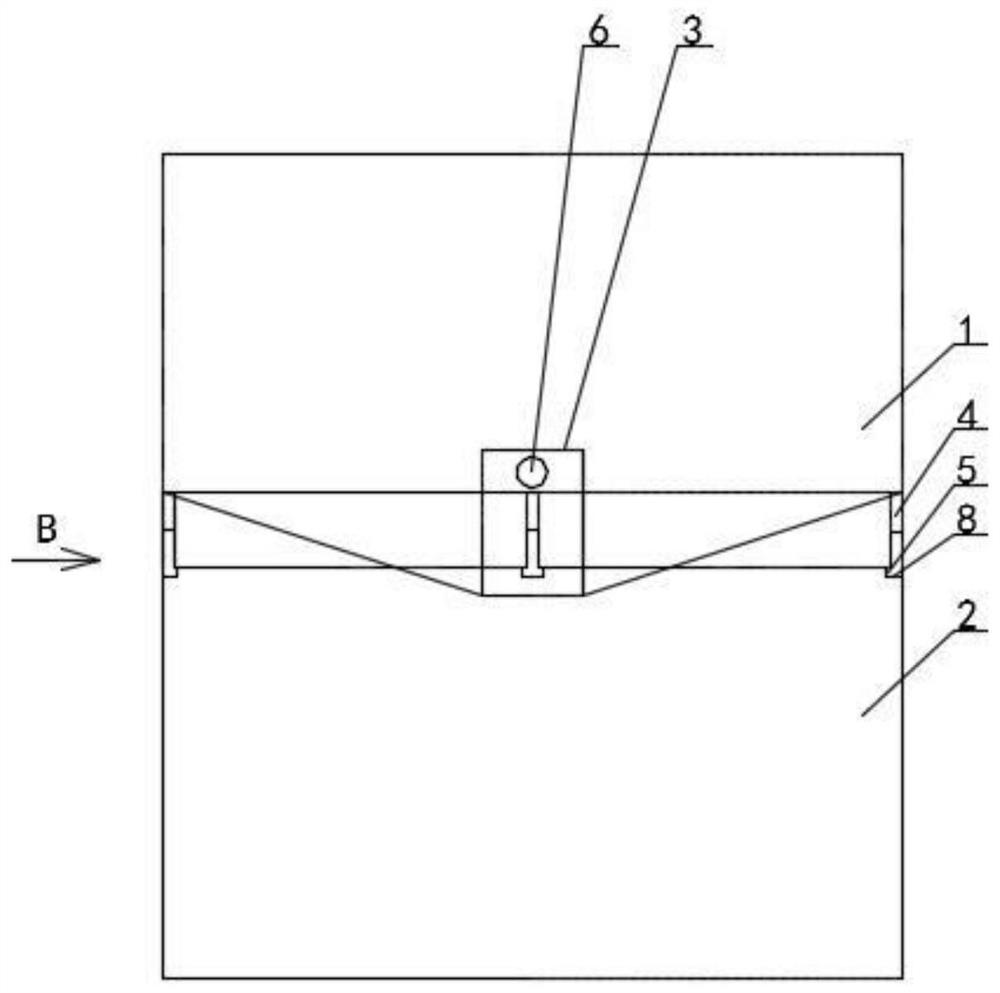

[0045] as attached figure 1 , 2 As shown, the special test device in this embodiment is mainly composed of an upper box 1, a lower box 2, and a communication tube 3, and each part is not made of plexiglass.

[0046] The upper box 1 is in the shape of a square funnel, the upper part is a square tube with a length of 20cm, a width of 10cm and a height of 3cm; . The connecting tube 3 is 1.5 cm high, and the cross section is a square with a side length of 1 cm. Both ends of the upper box 1 in the length direction are fixed with support columns 4 with a length of 2.5 cm, and the lower ends of the support columns 4 are processed with tabs 5 . The lower port of the communication pipe 3 and the tab 5 are on the same plane. Two drainage holes 6 with a diameter of 0.5 cm are respectively machined on the inclined surfaces on both sides of the upper box 1 in the width direction, which are slightly lower than the position along the plane of the communication pipe 3 . Both the two drai...

Embodiment 2

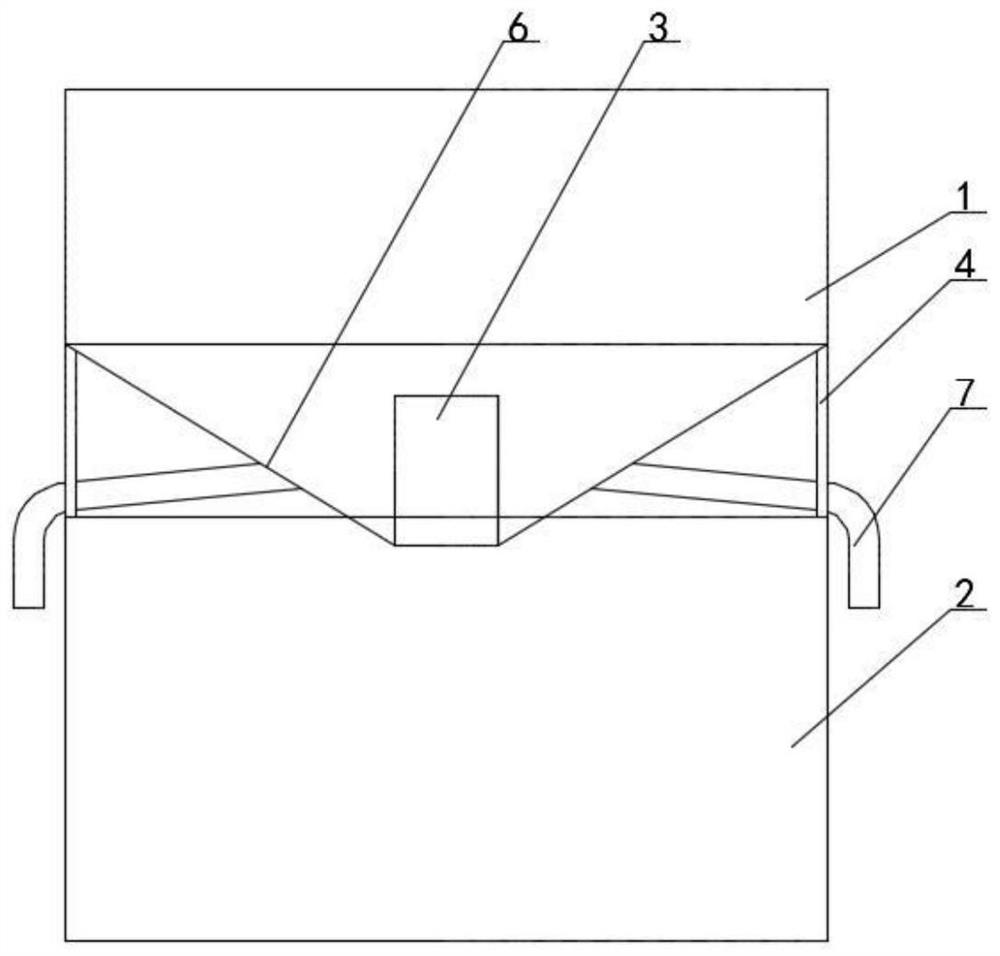

[0049] as attached image 3 , 4As shown, the special test device in this embodiment is mainly composed of an upper box 1, a lower box 2, and a communication tube 3, and each part is not made of plexiglass.

[0050] The upper box 1 is in the shape of a cylindrical funnel, the upper half is cylindrical with a radius of 10 cm and a height of 4 cm; the bottom surface of the lower half is inclined downward from the lower end of the upper half, and is connected with the lower mouth of the communication pipe 3 at the center of the bottom. . The connecting tube 3 is 2 cm high, and the cross section is a circle with a radius of 0.5 cm. Four support columns 4 with a length of 1 cm are fixed at the lower end of the side wall of the upper box 1 , and the lower end of the support columns 4 is processed with a tab 5 . The lower port of the communication pipe 3 and the tab 5 are on the same plane. Two drainage holes 6 with a diameter of 0.5 cm are machined at the lower end of the side wa...

Embodiment 3

[0054] According to the maximum water-holding capacity of the substrate used, mix an appropriate amount of water with the substrate to make it reach 70-80% of the maximum water-holding capacity, and put the mixed substrate in the upper box of Example 1, about 1cm away from the edge of the upper layer, Weigh and record the weight of the loaded matrix. Fill the lower box with the mixed substrate, weigh and record the weight of the loaded substrate. Put the tabs on both sides of the lower part of the upper box into the slot of the lower box, so that the upper and lower boxes are stuck and fixed, so that the matrix in the communication tube of the upper box is in close contact with the matrix in the lower box without leaving a gap. If you need to move it later, you should support the bottom of the lower box. Put cotton seeds in the center of the upper box, just above the orifice of the connecting pipe, and the depth of the seeds is about 1.5cm. Cotton seedlings emerged 1 week la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com