Production facility and production method for cultivating fresh grass through seeds

A fresh grass and seed technology, applied in the field of plant cultivation, can solve the problems affecting the yield and quality of livestock, the inability to obtain fresh grass feed, and reducing the supply of effective nutrition for livestock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

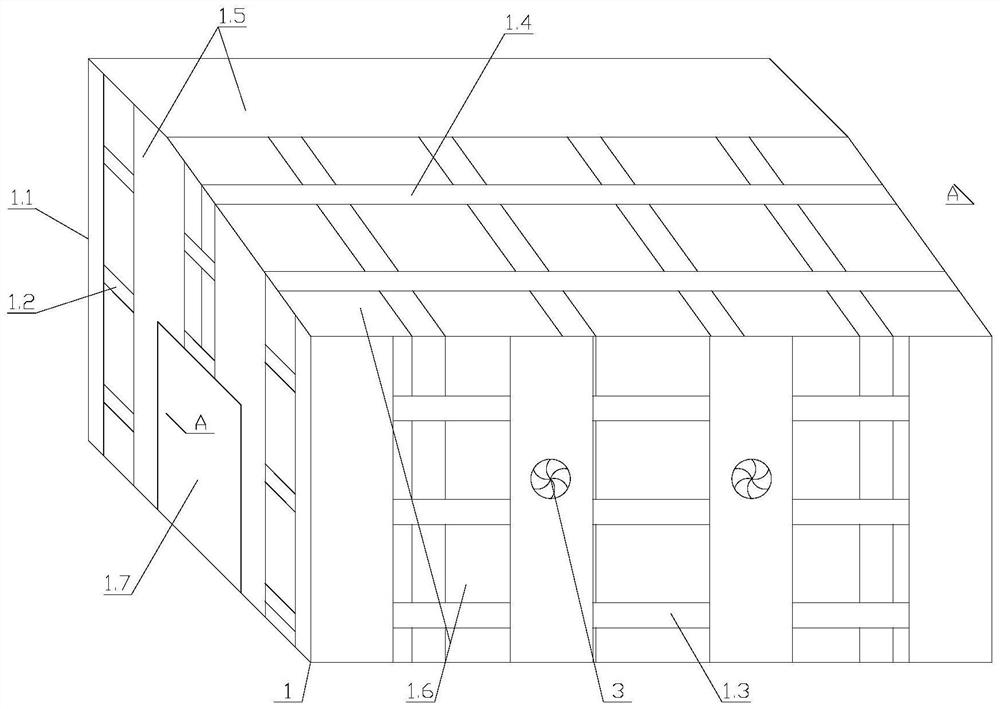

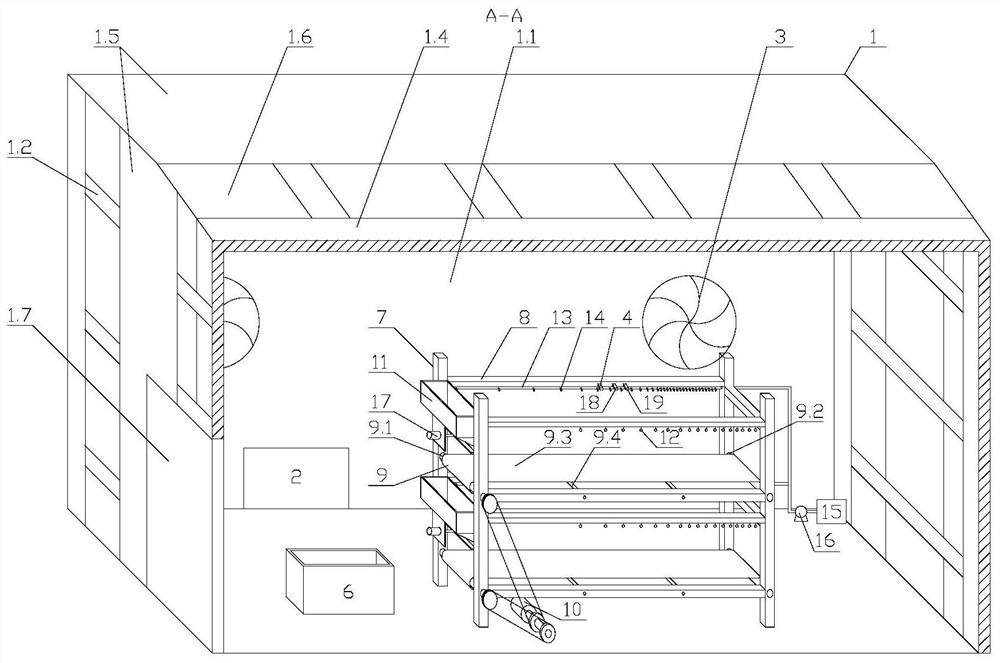

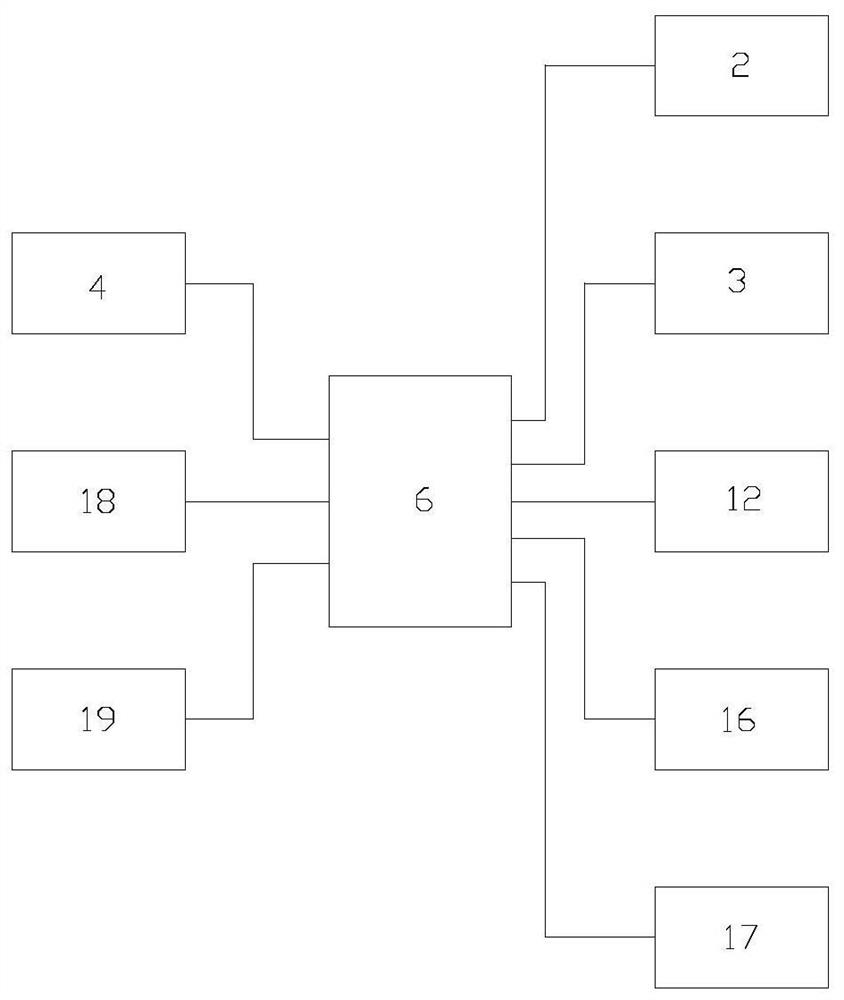

[0030] Embodiment 1: as Figure 1-4 As shown, a production facility for cultivating fresh grass from seeds, which includes a lighting and heat preservation room body 1, a heating facility 2, a ventilation facility 3, a humidity sensor 4, a light sensor 18, a temperature sensor 19 and a controller 5; Including the back wall 1.1, the gable frame 1.2, the front wall frame 1.3 and the roof frame 1.4; on the gable frame 1.2 and the front wall frame 1.3, the insulation board 1.5 and the hollow insulation glass 1.6 are fixed at intervals, and the insulation board 1.5 ensures the lighting and heat preservation of the room body 1 has good thermal insulation, and the hollow thermal insulation glass 1.6 ensures that the daylighting and thermal insulation room body 1 has good light transmission while thermal insulation; a door 1.7 is also arranged on the gable frame 1.2; a part of the roof frame 1.4 close to the rear wall 1.1 The insulation board 1.5 is fixedly laid on the side, and the i...

Embodiment 2

[0037] Embodiment 2: Utilize the method for the production facility described in embodiment 1 to produce fresh grass, it comprises the following steps: (1) seed selection; (2) seed soaking; (3) seed distribution; (4) continuous seedling cultivation; (5) collect fresh grass;

[0038] (1) Seed selection: select seeds with a germination rate of more than 90%, and use clear water or a sterilizing solution with a bactericidal effect to clean the seeds;

[0039] (2) Seed soaking: the seeds cleaned in step (1) are placed in the seed soaking tank 6, soaked in warm water with a temperature of 20°C for 6 hours, and taken out;

[0040] (3) Seed distribution: add the seeds fished out in step (2) to the seed distribution machine 11; control the electric flapper valve 17 to open through the controller 5, and simultaneously make the seedling raising conveyor belt 9.3 move forward slowly, and distribute the seeds The seeds in the machine 11 are slowly sprinkled onto the seedling raising conv...

Embodiment 3

[0046] Embodiment 3: Utilize the method for the production facility described in embodiment 1 to produce fresh grass, it comprises the following steps: (1) seed selection; (2) seed soaking; (3) seed distribution; (4) continuous seedling cultivation; (5) collect fresh grass;

[0047] (1) Seed selection: select seeds with a germination rate of more than 90%, and use clear water or a sterilizing solution with a bactericidal effect to clean the seeds;

[0048] (2) Seed soaking: the seeds cleaned in step (1) are placed in the seed soaking tank 6, soaked in warm water with a temperature of 30°C for 12 hours, and removed;

[0049] (3) Seed distribution: add the seeds fished out in step (2) to the seed distribution machine 11; control the electric flapper valve 17 to open through the controller 5, and simultaneously make the seedling raising conveyor belt 9.3 move forward slowly, and distribute the seeds The seeds in the machine 11 are slowly sprinkled onto the seedling raising conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com