A construction method for cleaning the clogged screen hole of vibrating screen

A construction method and vibrating screen technology, applied in chemical instruments and methods, filter screens, solid separation, etc., can solve the problems of poor working environment, long time for vibration cleaning, and much dust, and achieve poor resonance effect and vibration efficiency. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described below, but the scope of claims is not limited to the above.

[0026] join Figure 1 to 2 Indicated.

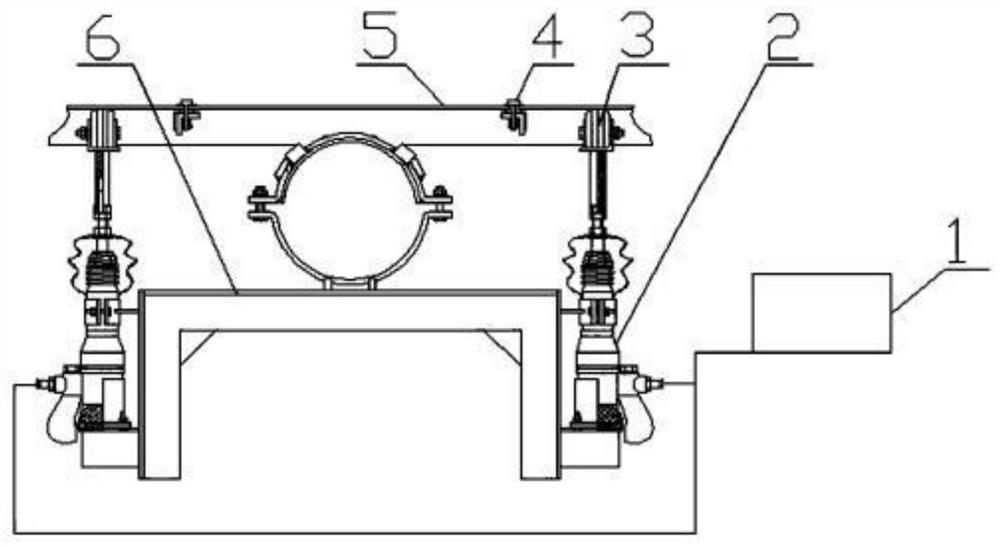

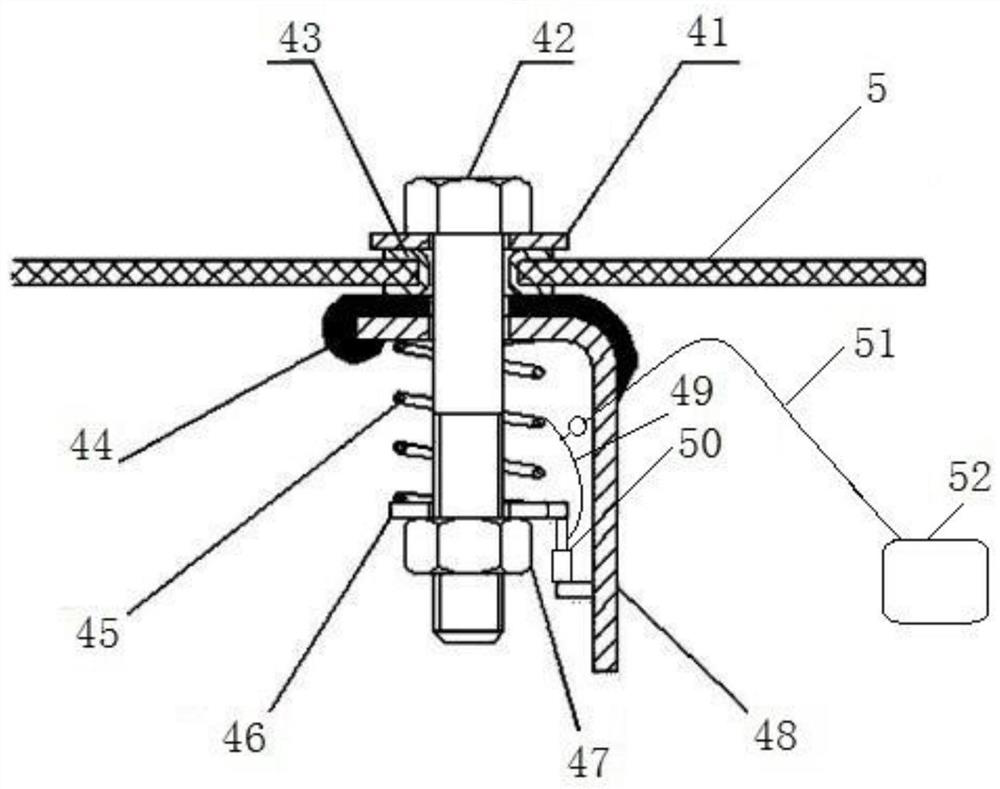

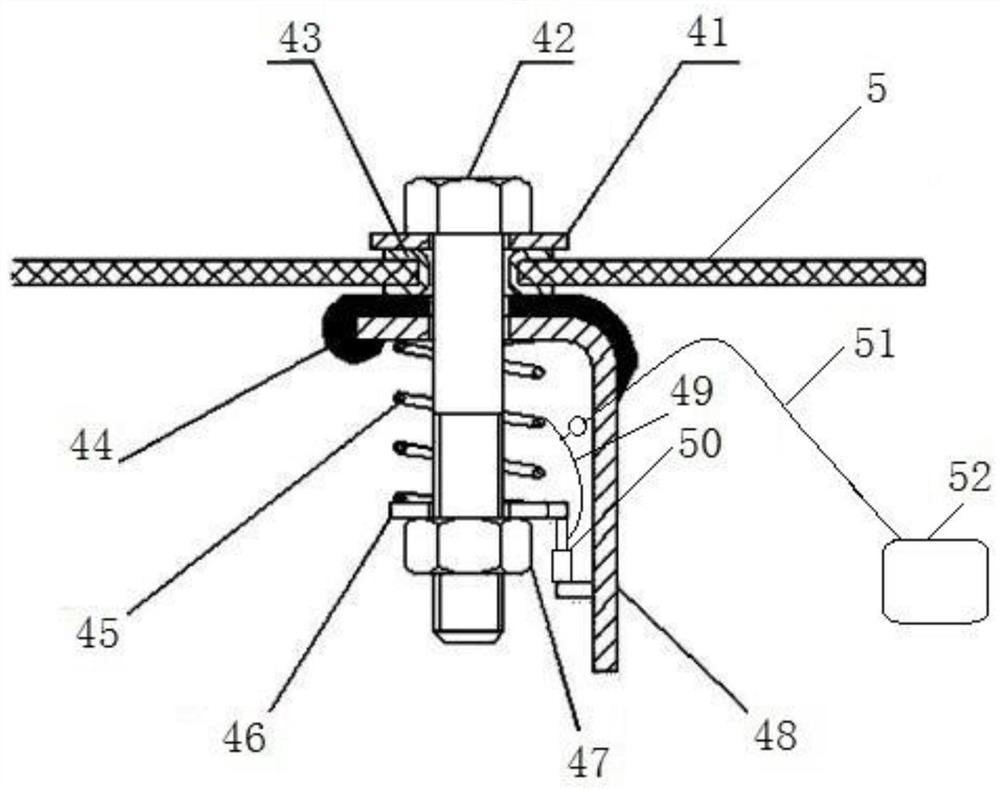

[0027] A vibrating screen of the present invention is blocked the cleaning system, including: the vibrating screen 5 and the resonator 4 that adjust the resonance damping coefficient, the screen of the vibrating screen 5 is mounted on the rack through the resonator 4.

[0028] When the vibrating screen 5 is or vibrated, the damping coefficient of the resonator 4 is adjusted, improve the resonance effect, and the vibration efficiency is increased, and the time required to vibrate cleanup is shortened.

[0029] It also includes a control system 1, a support device 6 secured to the rack of the vibrating screen 5, and the drive device 2 attached to the support device 6 and mounted on the support device 6, and is installed below the vibrating screen 5 screen. The hammer head 3 on the drive device 2.

[0030] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com