A preparation method of γ-tial alloy with preferential orientation of lamellar interface and fine lamellar characteristics

A preferred orientation and interface technology, applied in the field of TiAl intermetallic compounds, can solve problems such as insufficient high temperature performance and poor room temperature plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

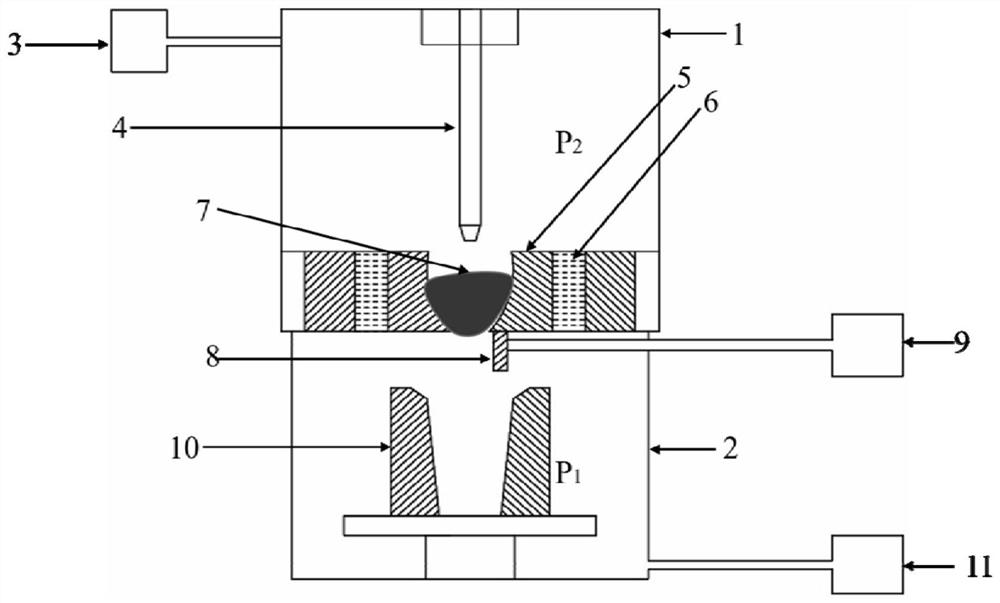

Method used

Image

Examples

Embodiment

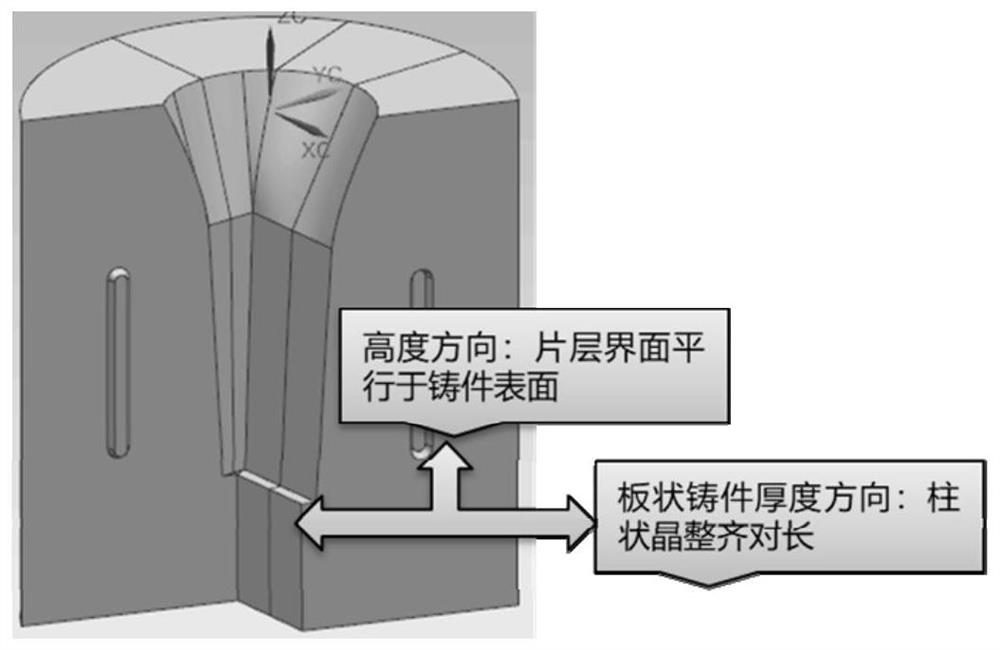

[0032]In this embodiment, the selected alloy composition is Ti-48Al-2Cr-2Nb (at%), and its primary phase is α; the selected metal mold 10 is a thick-walled steel mold without preheating, and the cavity of the metal mold 10 is Plate-like, with the largest temperature gradient in its thickness direction, and satisfying In the formula, G is the actual temperature gradient in the liquid phase at the front of the solid-liquid interface (K / μm), R is the crystal growth rate (the advancing speed of the solid-liquid interface into the liquid phase) (μm / s), and m is the phase diagram Slope of the upper liquidus (dimensionless), c 0 is the solute content (%), k 0 is the solute partition coefficient (dimensionless), and D is the diffusion coefficient of the solute in the liquid phase (μm 2 / s). Since the primary phase of Ti-48Al-2Cr-2Nb is α, the α phase preferentially grows along the [0001] direction in the thickness direction, forming a neat and long α columnar crystal; the lamellar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com