High-smoothness grinding machine for inner hole of straight hole

A high-gloss, grinding machine technology, applied in the direction of grinding machine tools, grinding tools, grinding devices, etc., can solve the problems of low processing efficiency, high processing cost of straight holes and inner holes, etc., achieve low single machine cost, improve grinding effect, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

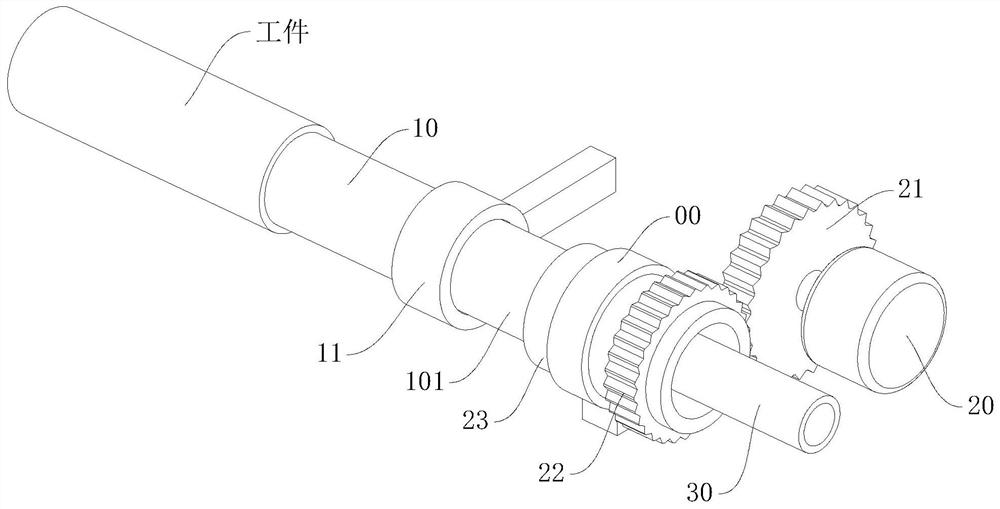

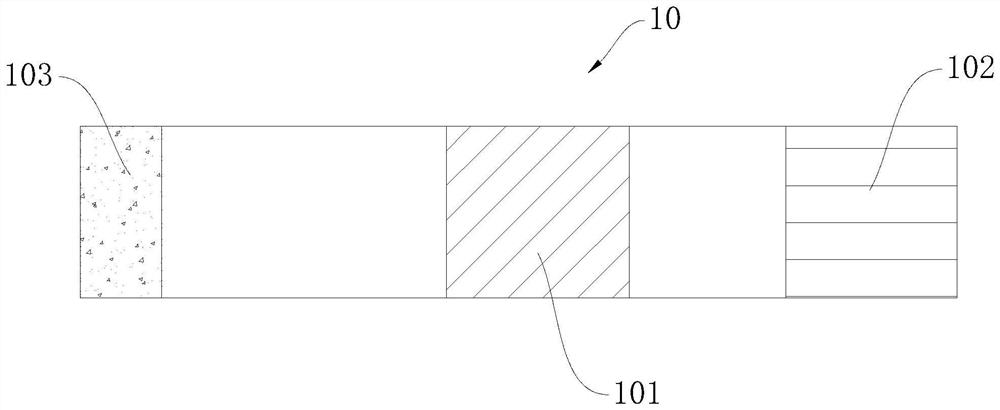

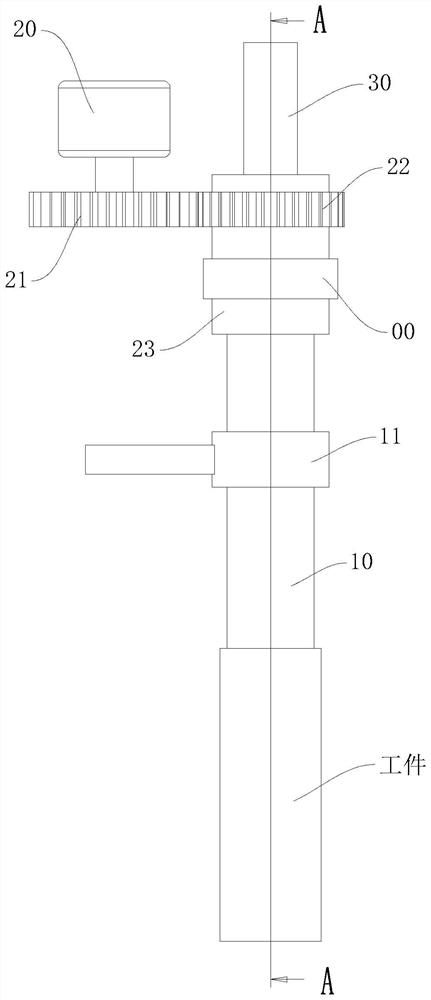

[0035] Such as Figure 1 to Figure 4 As shown, a straight hole inner hole high-gloss grinding machine provided by the embodiment of the present invention includes: a support 00; a grinding shaft 10, one end of which has a grinding head 1031 for grinding the inner hole of a workpiece; a driving device , which includes a power unit and a drive ring 11, and the drive ring 11 is fixedly arranged on the support 00, such as figure 2 As shown, the grinding shaft 10 at least includes a grinding section 103, a screw section 101 and a spline section 102 arranged in sequence, and the screw section 101 is a driving screw; hole, when the grinding shaft 10 rotates, the drive ring 11 drives the grinding shaft 10 to move axially;

[0036] The power device includes a drive motor 20 and a power ring 23, the power ring 23 is provided with an internal spline matched with the spline section 102, and the spline section 102 is provided with an external spline, and the internal spline cooperates wi...

Embodiment 2

[0040] On the basis of Example 1, due to the small machining allowance and high dimensional accuracy requirements during grinding, frequent inspection after grinding is required, which reduces the processing and inspection efficiency, such as Figure 7 As shown, therefore the grinding section 103 includes a step-off section 1081, a pass-through section 1082 and a pass-through section 1083. The diameter of the pass-through section 1081 is smaller than the diameter of the inner hole of the workpiece, and the outer diameter of the pass-through section 1082 is the lower diameter of the inner hole of the workpiece. The limit value, the outer diameter of the no-pass section 1083 is the upper limit of the diameter of the inner hole of the workpiece, and the diameter of the relief section 1081 is smaller than the diameter of the relief section 1081. During the grinding process, if the grinding size exceeds the inspection section 1082, the inspection section 1082 can enter, indicating t...

Embodiment 3

[0044] On the basis of Embodiment 1 or 2, since the grinding head 1031 with a fixed size is used for many times, the outer diameter of the grinding head 1031 will become smaller, resulting in a smaller diameter of the grinding hole, and it is necessary to replace the new grinding head 1031 frequently. , resulting in higher processing costs, so in this embodiment, such as Figure 5 and Figure 6 As shown, the grinding head 1031 includes a support block 12, a connecting rod 105, an elastic pad 107 and a grinding layer 106, the support block 12 is connected to one end of the grinding shaft 10 through the connecting rod 105, and an air inlet 104 is provided in the grinding shaft 10 , an air intake pipe 30 is externally connected to the end of the air intake hole 104 along the advancing direction of grinding, as Figure 6 As shown, the elastic pad 107 is a ring structure, and its two ends are respectively sealed and connected to the grinding shaft 10 and the support block 12. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com