Three-centimeter flush all-in-one machine for machining interior door frame

An integrated, indoor door technology, used in wood processing appliances, special forming/shaping machines, manufacturing tools, etc., can solve problems affecting the aesthetics of door frames, and achieve the effect of no damage to the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

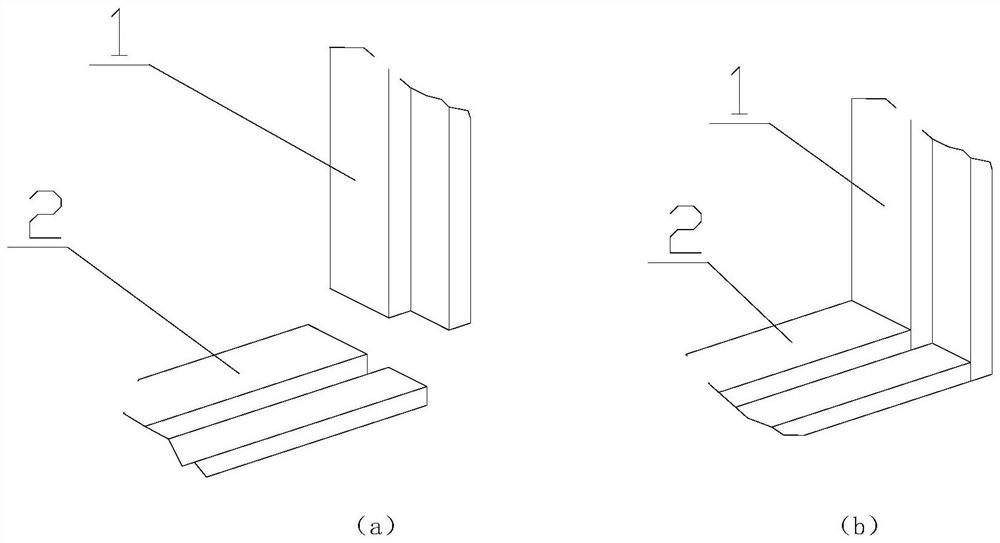

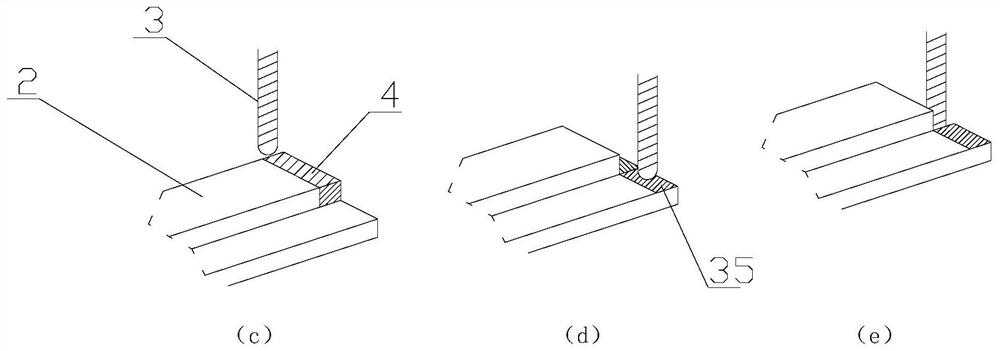

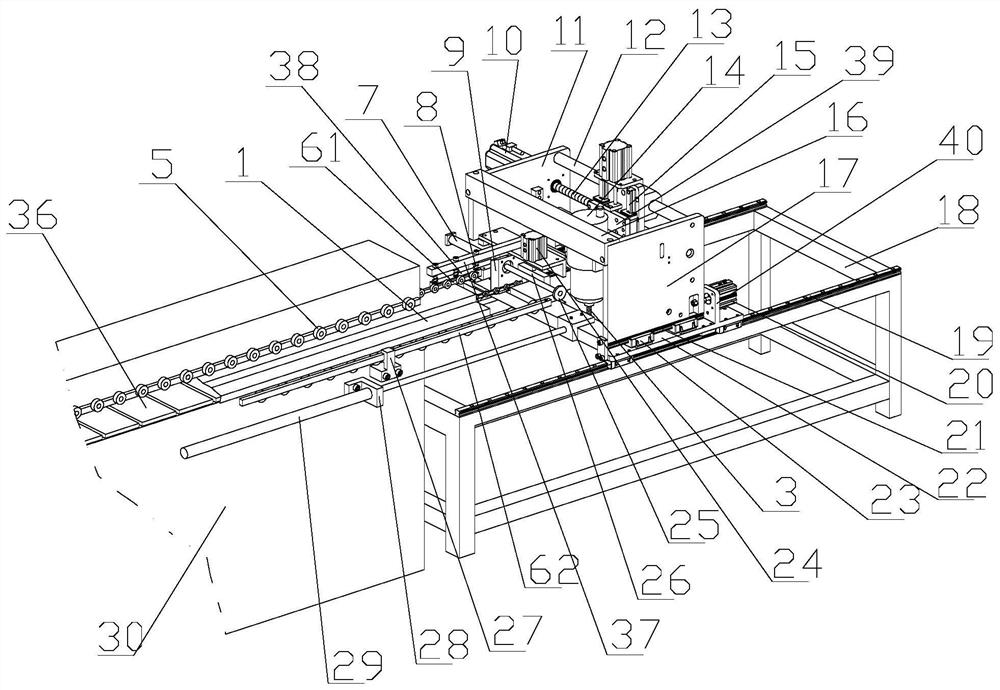

[0019] refer to Figure 1 to Figure 5 , a three-centimeter all-in-one machine for indoor door frame processing, including a bracket 18, a plate and profile conveying mechanism body 30 and a tool milling assembly mechanism ( Figure 4 shown).

[0020] combine image 3 As shown, there is a conveyor belt 36 and an upper pressure roller 5 on the door frame plate profile conveying mechanism body 30, the door frame profile plate 1 is installed on the conveyor belt 36, and is pressed with the upper pressure roller 5, and the conveyor belt 36 transports the door frame profile plate 1 Towards the tool milling combination mechanism ( Figure 4 shown) direction to move.

[0021] combine image 3 , Figure 4 As shown, the tool milling combination mechanism consists of three sets of line rails, two stroke cylinders, an upper left support rod 61, a lower left support rod, a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com