Forming method and device for brick-type bags

A bag forming and brick-shaped technology, which is applied in the field of brick-shaped bag forming methods and forming devices, can solve the problems of low bag forming efficiency, poor packaging bag forming neatness, inconvenient stacking and transportation, etc., so as to ensure the continuity of packaging , improve packaging efficiency, improve the effect of vacuuming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

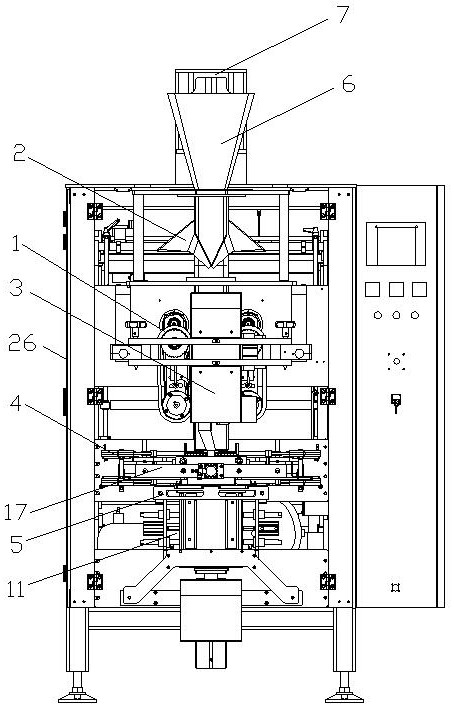

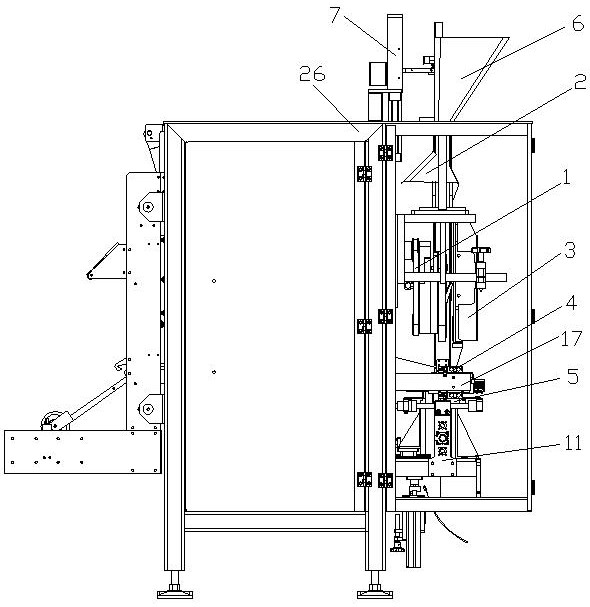

[0060] see figure 1 , figure 2 , Figure 5 and Figure 6 , a kind of brick type bag forming method, comprises the following steps:

[0061] a. First, the film is pulled into the collar former 2 by the film pulling mechanism 1, and the film is rolled into a cylinder through the collar former 2;

[0062] b. The film pulling mechanism 1 pulls the rolled-up cylindrical film into the middle sealing mechanism 3, and performs middle sealing through the middle sealing mechanism 3, and then the film pulling mechanism 1 pulls the middle-sealed cylindrical film into the pin mechanism In 4, the bottom is pinned through the pin mechanism 4;

[0063] c. The bottom of the cylindrical film is pre-clamped and sealed through the pre-clamping mechanism 5, and the material is added into the cylindrical packaging bag by the feeding mechanism 6, and then the upper end of the cylindrical packaging bag is sealed by the pin mechanism 4. pin;

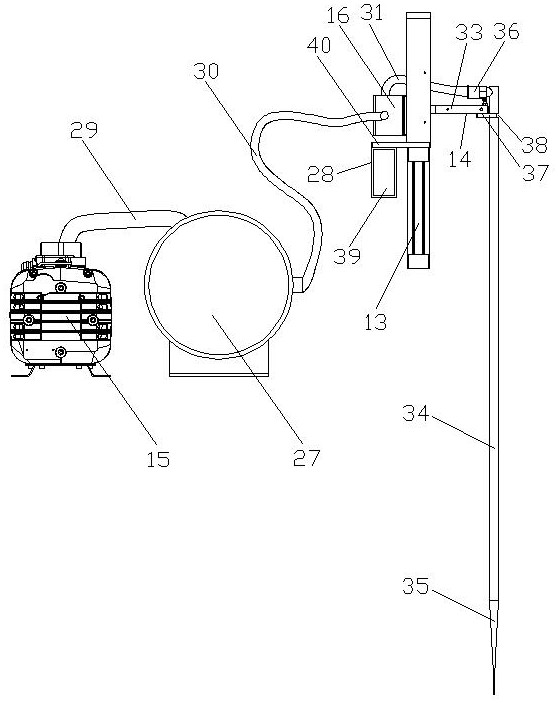

[0064] d. The packaging bag is evacuated by the vac...

Embodiment 2

[0067] see Figure 1-Figure 6 , a kind of brick type bag forming method, comprises the following steps:

[0068] a. First, the film is pulled into the collar former 2 by the film pulling mechanism 1, and the film is rolled into a cylinder through the collar former 2;

[0069] b. The film pulling mechanism 1 pulls the rolled-up cylindrical film into the middle sealing mechanism 3, and performs middle sealing through the middle sealing mechanism 3, and then the film pulling mechanism 1 pulls the middle-sealed cylindrical film into the pin mechanism In 4, the bottom is pinned through the pin mechanism 4;

[0070] c. The bottom of the cylindrical film is pre-clamped and sealed through the pre-clamping mechanism 5, and the material is added into the cylindrical packaging bag by the feeding mechanism 6, and then the upper end of the cylindrical packaging bag is sealed by the pin mechanism 4. pin;

[0071] d. The packaging bag is evacuated by the vacuum mechanism 7, the sliding ma...

Embodiment 3

[0080] see Figure 1-Figure 6 , a kind of brick type bag forming method, comprises the following steps:

[0081] a. First, the film is pulled into the collar former 2 by the film pulling mechanism 1, and the film is rolled into a cylinder through the collar former 2;

[0082] b. The film pulling mechanism 1 pulls the rolled-up cylindrical film into the middle sealing mechanism 3, and performs middle sealing through the middle sealing mechanism 3, and then the film pulling mechanism 1 pulls the middle-sealed cylindrical film into the pin mechanism In 4, the bottom is pinned through the pin mechanism 4;

[0083] c. The bottom of the cylindrical film is pre-clamped and sealed through the pre-clamping mechanism 5, and the material is added into the cylindrical packaging bag by the feeding mechanism 6, and then the upper end of the cylindrical packaging bag is sealed by the pin mechanism 4. pin;

[0084] d. The packaging bag is evacuated by the vacuum mechanism 7, the sliding ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com