Full-automatic bottled film sleeving machine

A laminating machine and fully automatic technology, applied in packaging, packaging bottles, wrapping paper, etc., can solve problems affecting enterprise development, affecting enterprise order sales, increasing sales costs of finished products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

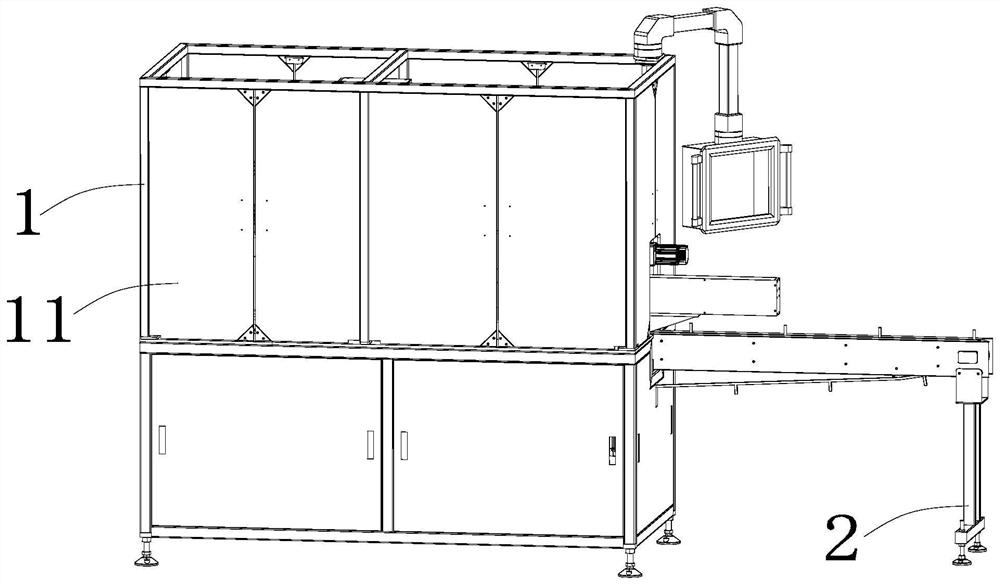

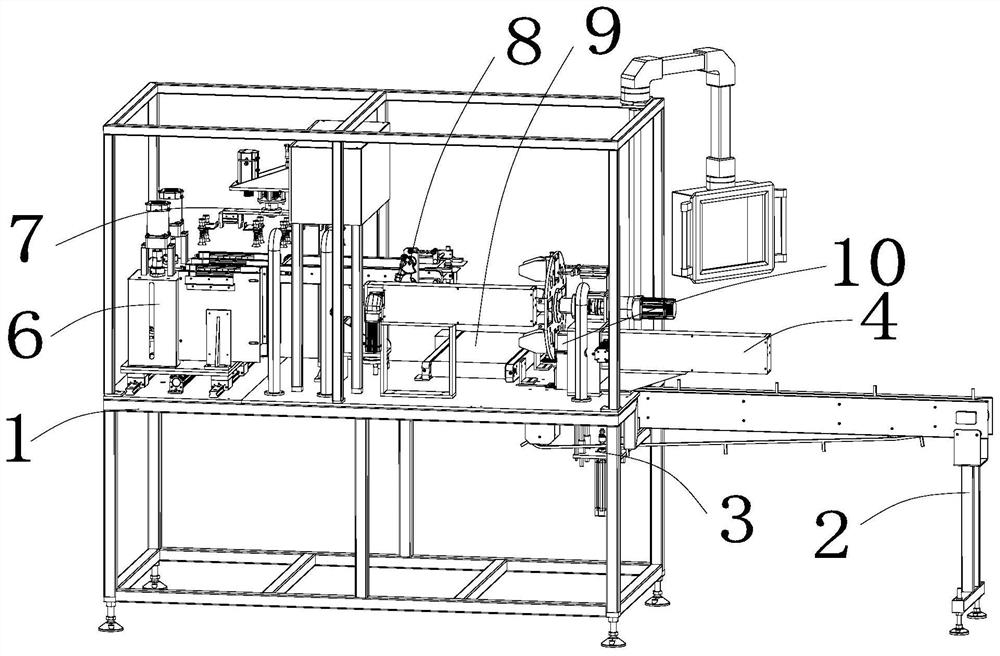

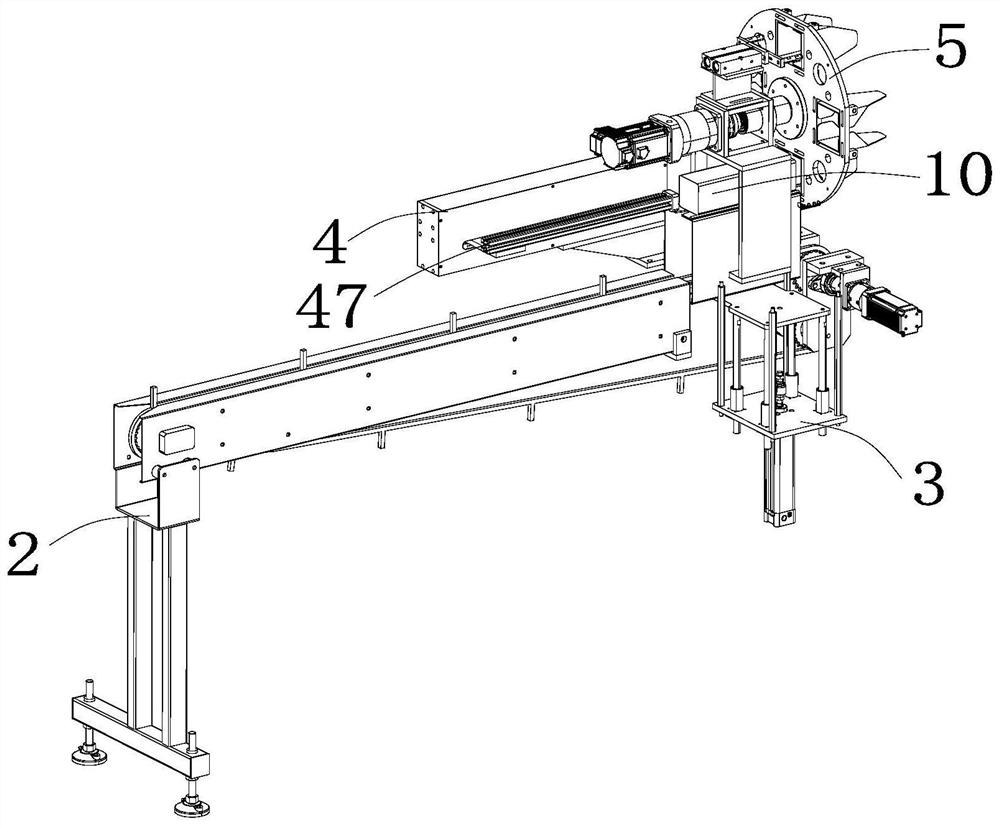

[0041] Embodiment: a kind of full-automatic bottle-packing film machine, as attached figure 1 with 2 As shown, the bottle hooding machine in the present embodiment comprises a frame 1, and the frame 1 is a frame structure, and the outer surface of the frame structure is provided with a protective shell 11, so that the working production line of the bottle hooding machine is isolated from the external environment, so as to avoid The external environment affects the normal operation of the production line; a frame plate is fixed at an appropriate height of the frame structure, and a bottle conveying mechanism 2, a bottle lifting mechanism 3, a bottle pushing mechanism 4, and a bag guiding mechanism are fixed on the frame 1 plate 5. Bag storage mechanism 6, bag grasping mechanism 7, bag opening translation mechanism 8, finished product conveying mechanism 9; bottle body conveying mechanism 2 is used to convey the bottle body 10 to be coated, and the bottle lifting mechanism 3 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com