Closed belt conveyor with dust escape prevention structure

A belt conveyor, anti-escape technology, applied in the direction of conveyor, transportation and packaging, loading/unloading, etc., can solve the problems of dust escaping and poor dust prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

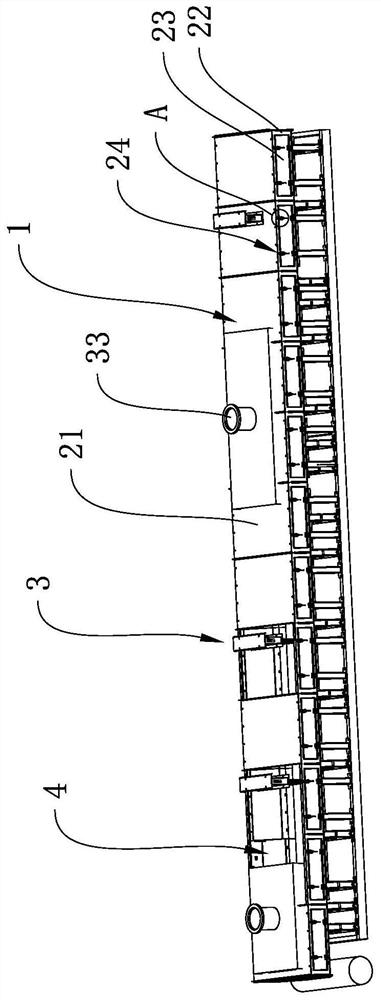

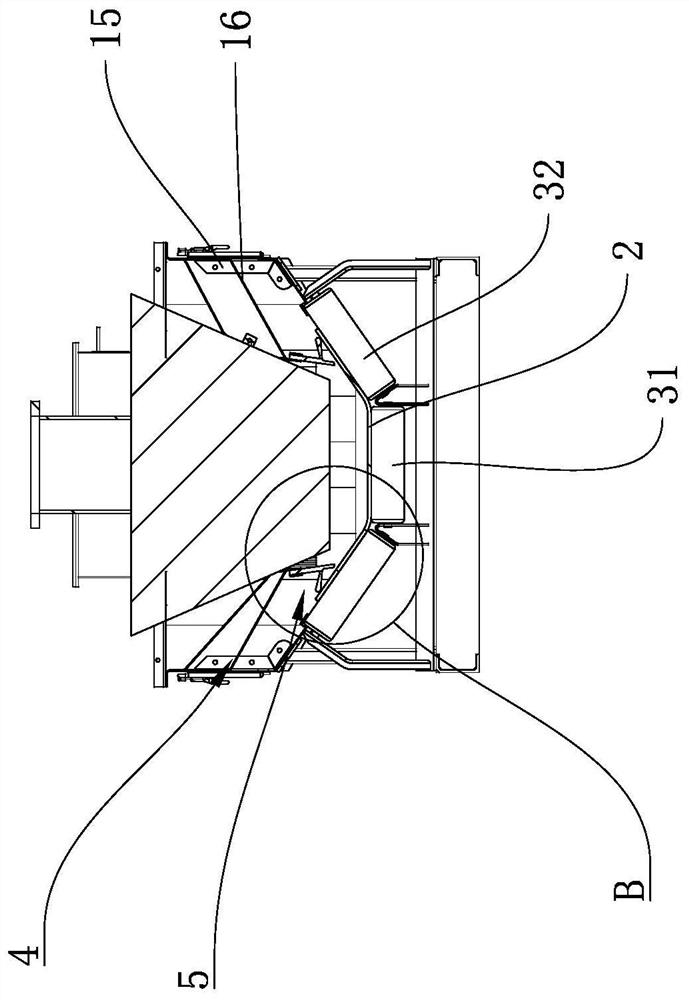

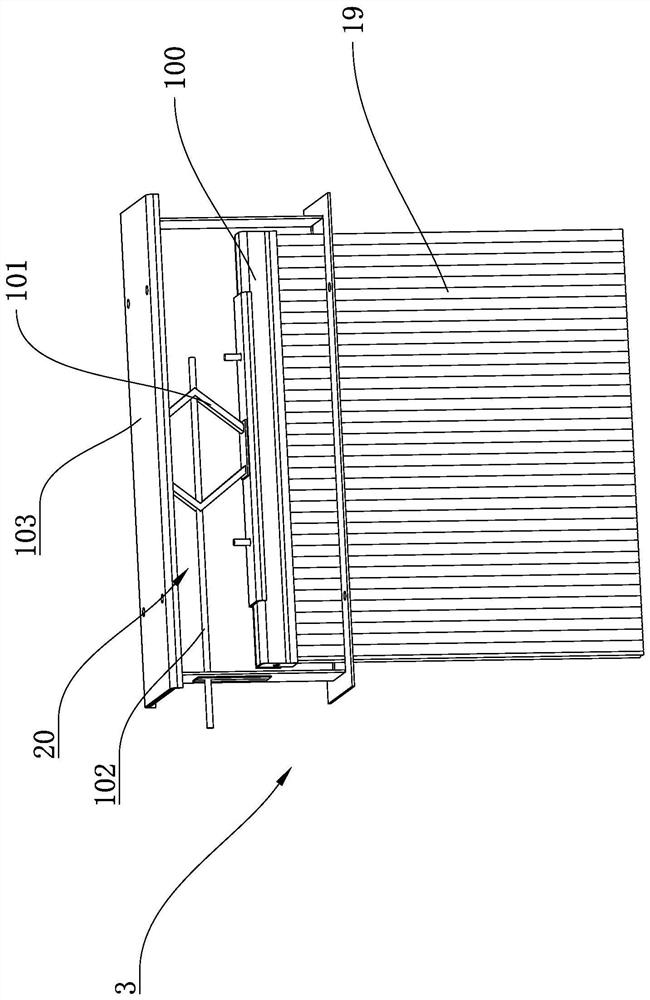

[0030] Such as figure 1 with figure 2 As shown, a closed belt conveyor with a dust-proof structure includes a body 1 and a conveyor belt 2 arranged in the body 1. Several floating dust capture mechanisms 3 are arranged in the body 1 along the conveying direction of the conveyor belt 2. , the two sides of the body 1 are also provided with deflector structures 4 , and an adjustable dust-proof assembly 5 is provided between the deflector structures 4 and the conveyor belt 2 .

[0031] In this embodiment, the deflector structure 4 can prevent floating dust from accumulating on the inner wall of the body, and several floating dust capture mechanisms 3 arranged along the conveying direction of the conveyor belt 2 can capture the floating dust generated during the conveying process. When the captured floating dust accumulates to a certain weight Finally, it will slide to the surface of the conveyor belt under the action of gravity and move forward with the material. The adjustable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com