Near-field suspension and static pressure suction coupled suspension grabbing system

An adsorption phase and static pressure technology, applied in non-mechanical conveyors, transportation and packaging, conveyors, etc., can solve the problems of product damage, inability to maintain the stability of suspended objects, etc., and achieve safe and reliable use, low noise, The effect of simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings.

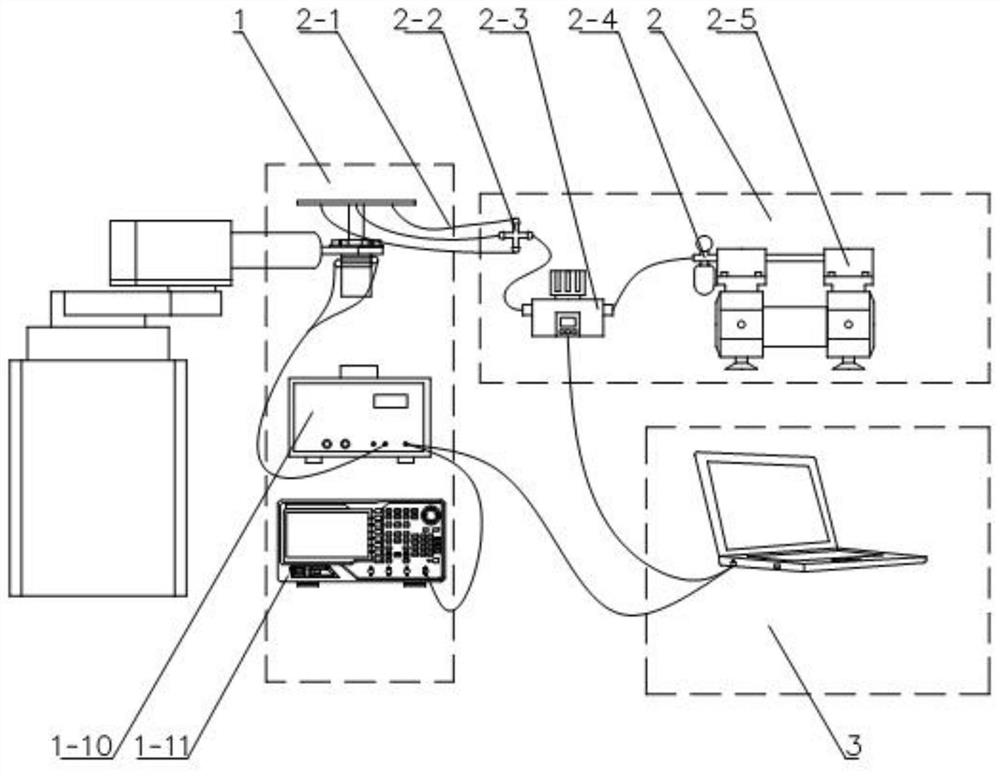

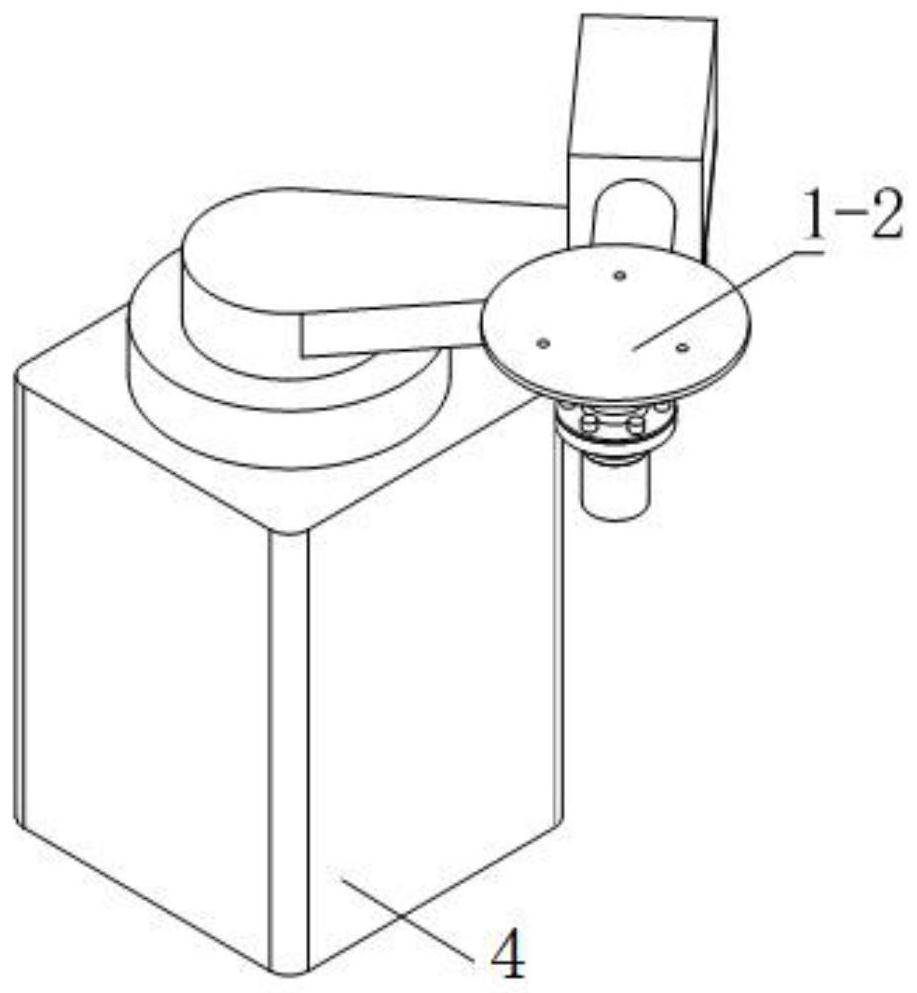

[0031] Such as figure 1 As shown, a suspension grasping system coupled with near-field suspension and static pressure adsorption includes an ultrasonic suspension excitation device 1 , a static pressure adsorption device 2 , a control system 3 , and a robotic arm 4 .

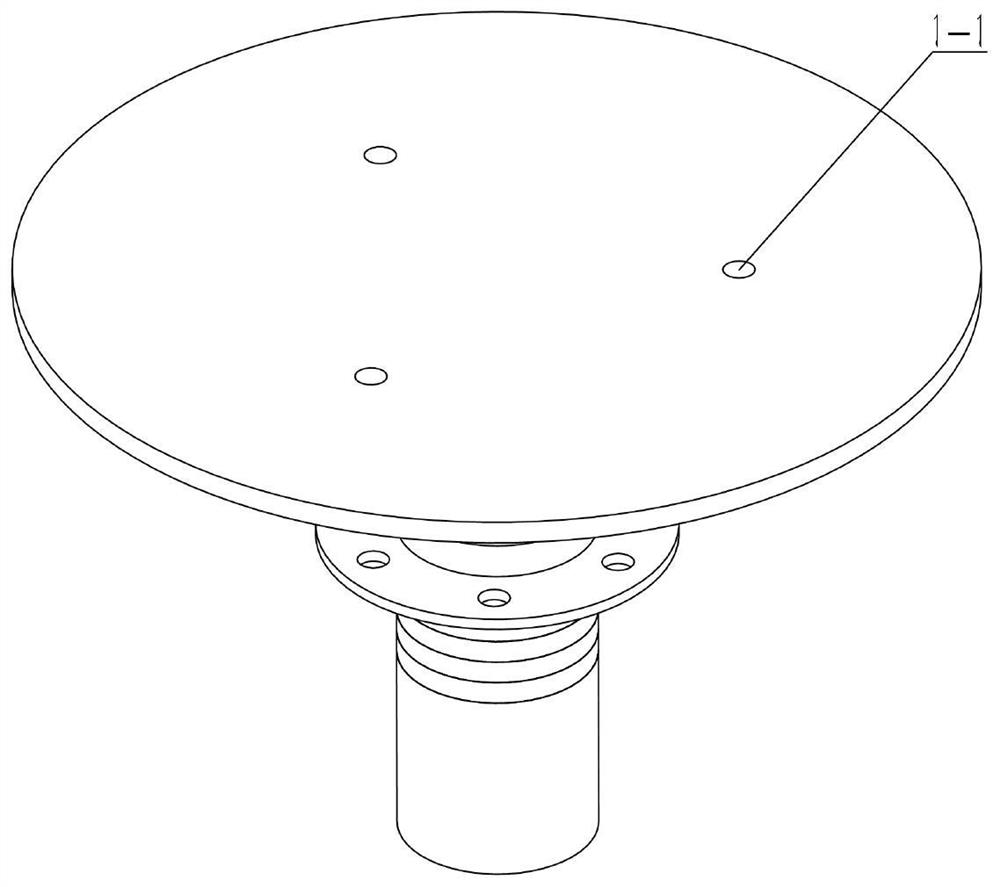

[0032] Such as Figure 5 to Figure 7 As shown, the ultrasonic levitation excitation device 1 includes a piezoelectric transducer, a radiation disk 1-2, a stabilized power supply 1-10, and an ultrasonic signal generator 1-11. The piezoelectric transducer includes ultrasonic horn 1-3, nodal flange 1-4, several piezoelectric ceramic sheets 1-5, several electrode sheets 1-6, insulating sleeve 1-7, rear cover 1- 8. Pre-tightening bolts 1-9. Ultrasonic horns 1-3, insulating sleeves 1-7, and rear cover plates 1-8 are arranged sequentially from top to bottom, and piezoelectric ceramic sheets 1-5 and electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com