Novel preparation method of electronic-grade CHF3

An electronic-grade and new technology, applied in the field of new preparation of electronic-grade CHF3, can solve the problems of not taking into account the boiling point parameters of trifluoromethane, reducing the effect of trifluoromethane, etc., so as to enhance the thermal convection effect, enhance the structural strength, and ensure isolation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

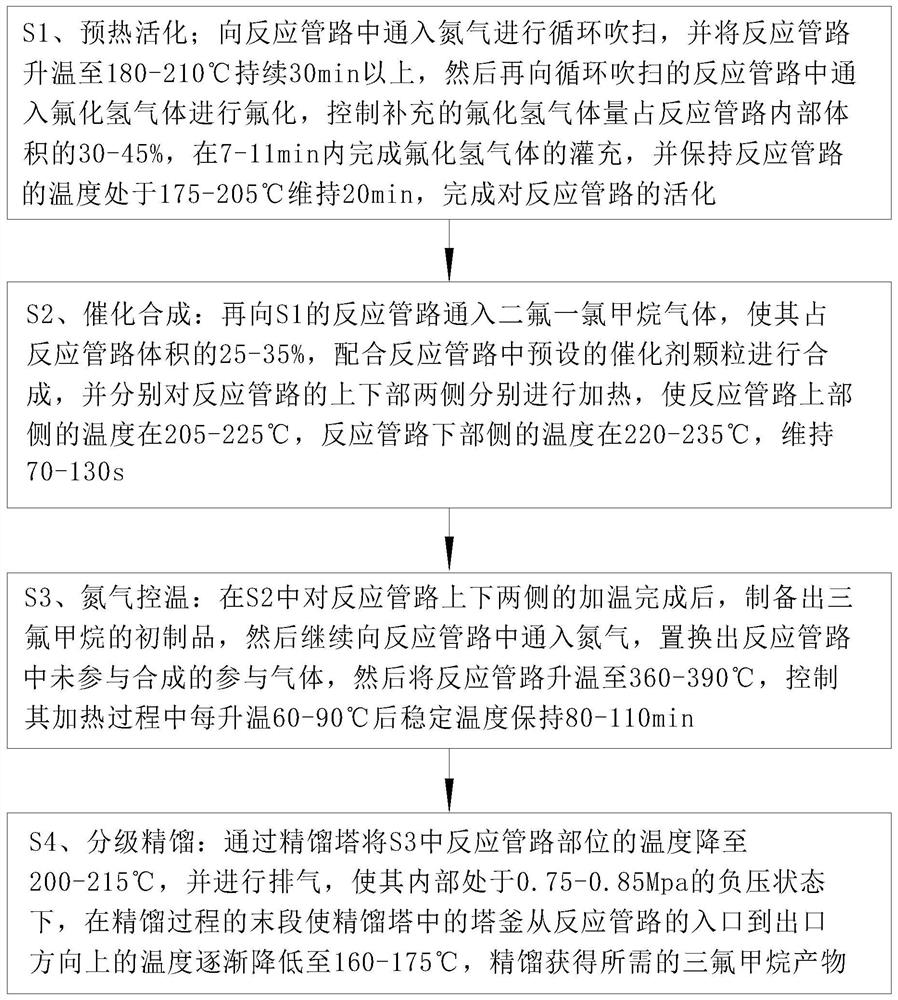

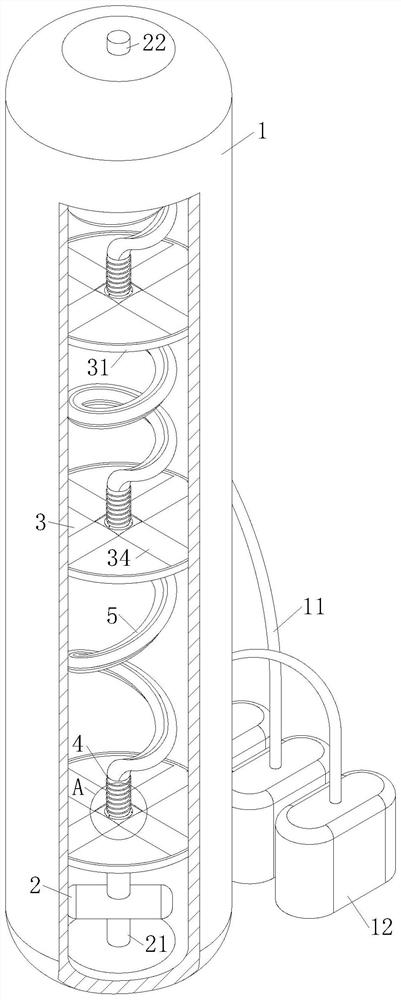

[0031] Such as Figure 1 to Figure 4 Shown, a kind of electronic grade CHF of the present invention Novel preparation method, this method step is as follows:

[0032] S1, preheating and activation; feed nitrogen into the reaction pipeline 2 for circular purging, and raise the temperature of the reaction pipeline 2 to 180-210°C for more than 30 minutes, and then pass into the circularly purged reaction pipeline 2 Hydrogen fluoride gas is used for fluorination, and the amount of supplemented hydrogen fluoride gas is controlled to account for 30-45% of the internal volume of the reaction pipeline 2. The filling of hydrogen fluoride gas is completed within 7-11 minutes, and the temperature of the reaction pipeline 2 is kept at 175-205°C Maintain for 20 minutes to complete the activation of the reaction pipeline 2;

[0033] S2. Catalytic synthesis: feed difluorochloromethane gas into the reaction pipeline 2 of S1 to make it account for 25-35% of the volume of the reaction pipeline...

Embodiment approach

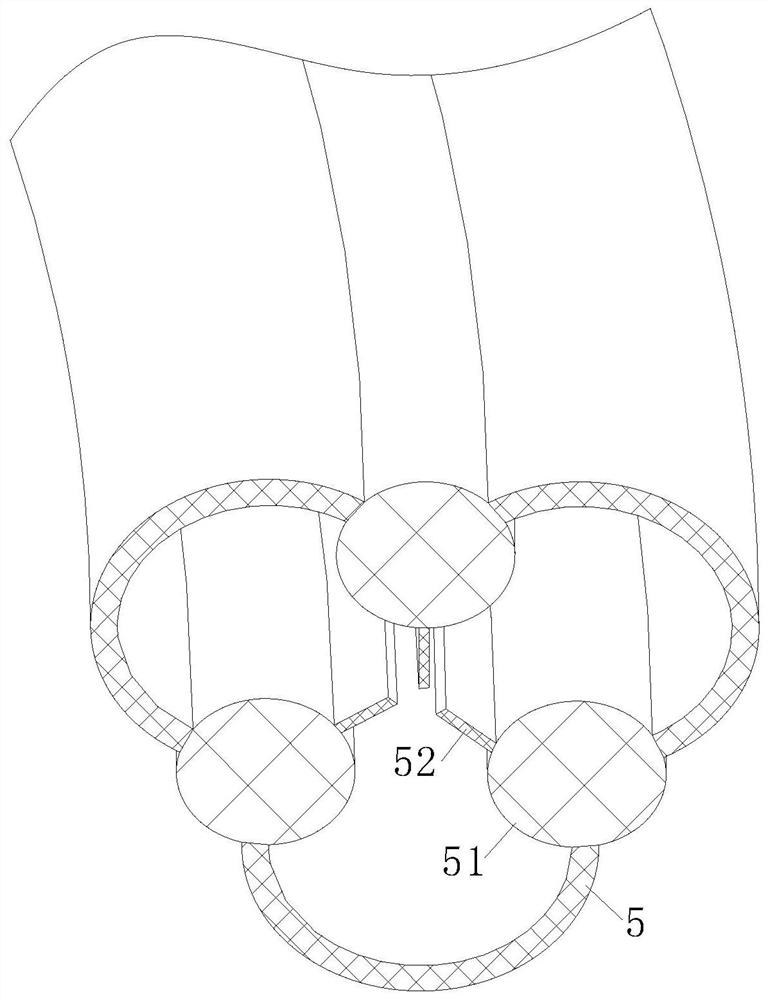

[0039] As an embodiment of the present invention, the center of the sealing diaphragm 3 is provided with an expansion hole 32, and the sealing diaphragm 3 is in sliding contact with the fractionating tube 4 through the expansion hole 32; an annular expansion bag 33 is also installed in the expansion hole 32 , the inside of the expansion bag 33 is divided into two independent upper and lower layers, and the expansion bag 33 is also provided with a port 331 on both sides of the sealing partition; when in use, the ring plate 31 on the inner wall of the tower kettle 1 is used to adjust the sealing diaphragm 3 In order to change the pressure of the cavity where the fractionation conduit 5 is located, the sealing diaphragm 3 will be deformed under the different pressure state on both sides; through the expansion hole 32 arranged in the center of the sealing diaphragm 3, cooperate with the installed expansion hole 32 The bladder 33, when the sealing diaphragm 3 is deformed due to pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com